News

How to reduce processing stress in sheet metal processing

Category:answer Publishing time:2025-09-16 10:42:38 Browse: Times

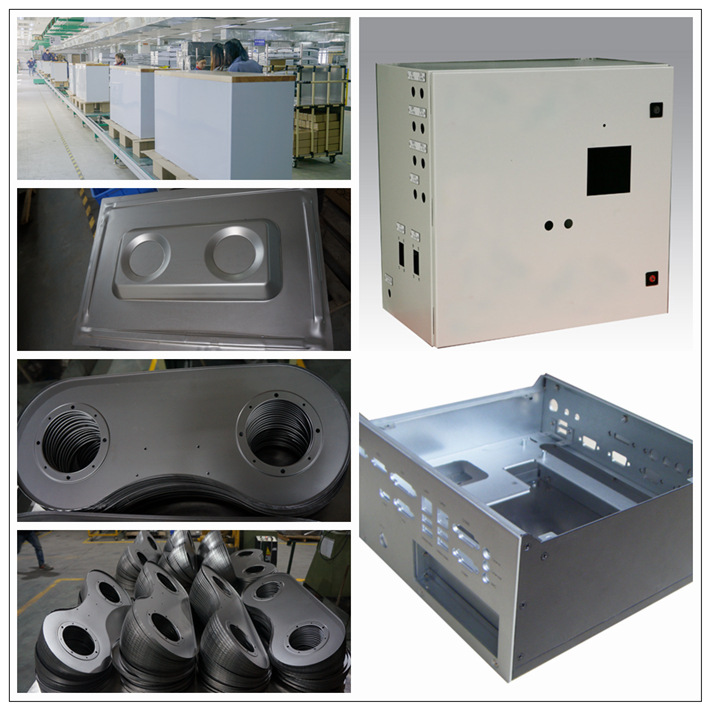

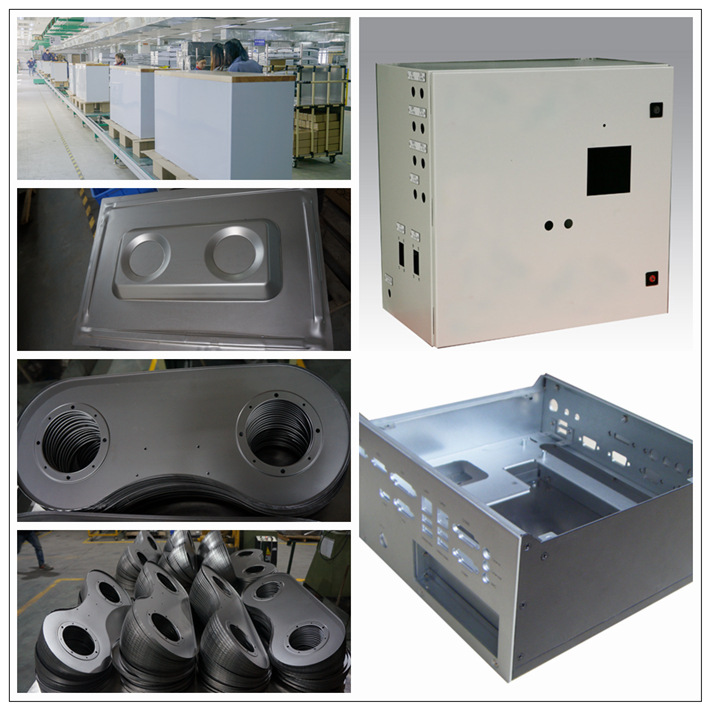

During the sheet metal processing process, when the material is subjected to external force, it will produce varying degrees of plastic deformation and elastic deformation, leading to the generation of processing stress. These stresses, if not eliminated or controlled in time, will not only affect the dimensional accuracy and shape stability of the workpiece but may also lead to deformation, cracking, and even affect the service life of the product. Therefore, how to reduce processing stress in sheet metal processing is a technical issue that cannot be ignored.

1. Reasonably select the processing technology

Different processing technologies produce different levels of stress on materials. For example, during the stamping forming process, if the stamping force is too large or the die clearance is unreasonable, it will cause the material to produce large plastic deformation and residual stress. Therefore, in the stage of process design, appropriate processing methods should be selected according to the material properties, thickness, and shape requirements, such as bending, deep drawing, and shearing, and the die parameters should be optimized to reduce stress concentration.

2. Adopt an appropriate forming speed

In the sheet metal processing process, the forming speed has a significant impact on the deformation behavior of the material. Excessive forming speed can cause rapid accumulation of internal stress in the material, increasing the risk of cracks and springback. Therefore, under the conditions allowed, a slower forming speed should be adopted for processing, allowing the material sufficient time to undergo plastic deformation and thus reduce internal stress.

3. Reasonably arrange the processing sequence

A reasonable processing sequence can effectively avoid the superposition of stress. Generally speaking, large-area or large deformation processing operations should be carried out first, followed by gradual local finishing. In addition, symmetrical processing helps to distribute stress uniformly, reducing stress concentration problems caused by asymmetric deformation.

4. Perform intermediate annealing treatment

For sheet metal parts with large deformation during processing, annealing treatment can be carried out at the intermediate stage of processing. Annealing can effectively release the residual stress inside the material, restore the plasticity and toughness of the material, and thus provide a good material state for subsequent processing. Common annealing methods include overall annealing and local annealing, which should be selected flexibly according to the part structure and processing requirements.

5. Use stress relief equipment and technology

Modern sheet metal processing enterprises can use some advanced equipment and technology to reduce processing stress, such as using vibration aging equipment, laser shock strengthening, and ultrasonic assisted processing. These technologies can effectively reduce the internal stress of the material without damaging the part structure, improving the dimensional stability and fatigue resistance of the part.

6. Optimize material selection

The tendency of work hardening and the plastic deformation capacity of different materials are different. Under the premise of meeting the performance requirements, it is advisable to choose materials with low work hardening tendency and good plasticity, which also helps to reduce stress accumulation during the processing process.

Conclusion

In summary, reducing processing stress in sheet metal processing is a systematic project that requires comprehensive consideration from multiple aspects such as design, technology, materials, and equipment. Through scientific and reasonable methods and means, not only can processing stress be effectively controlled, but the product quality and production efficiency can also be improved, extending the service life of the product, which has important practical significance and economic benefits.

During the sheet metal processing process, when the material is subjected to external force, it will produce varying degrees of plastic deformation and elastic deformation, leading to the generation of processing stress. These stresses, if not eliminated or controlled in time, will not only affect the dimensional accuracy and shape stability of the workpiece but may also lead to deformation, cracking, and even affect the service life of the product. Therefore, how to reduce processing stress in sheet metal processing is a technical issue that cannot be ignored.

1. Reasonably select the processing technology

Different processing technologies produce different levels of stress on materials. For example, during the stamping forming process, if the stamping force is too large or the die clearance is unreasonable, it will cause the material to produce large plastic deformation and residual stress. Therefore, in the stage of process design, appropriate processing methods should be selected according to the material properties, thickness, and shape requirements, such as bending, deep drawing, and shearing, and the die parameters should be optimized to reduce stress concentration.

2. Adopt an appropriate forming speed

In the sheet metal processing process, the forming speed has a significant impact on the deformation behavior of the material. Excessive forming speed can cause rapid accumulation of internal stress in the material, increasing the risk of cracks and springback. Therefore, under the conditions allowed, a slower forming speed should be adopted for processing, allowing the material sufficient time to undergo plastic deformation and thus reduce internal stress.

3. Reasonably arrange the processing sequence

A reasonable processing sequence can effectively avoid the superposition of stress. Generally speaking, large-area or large deformation processing operations should be carried out first, followed by gradual local finishing. In addition, symmetrical processing helps to distribute stress uniformly, reducing stress concentration problems caused by asymmetric deformation.

4. Perform intermediate annealing treatment

For sheet metal parts with large deformation during processing, annealing treatment can be carried out at the intermediate stage of processing. Annealing can effectively release the residual stress inside the material, restore the plasticity and toughness of the material, and thus provide a good material state for subsequent processing. Common annealing methods include overall annealing and local annealing, which should be selected flexibly according to the part structure and processing requirements.

5. Use stress relief equipment and technology

Modern sheet metal processing enterprises can use some advanced equipment and technology to reduce processing stress, such as using vibration aging equipment, laser shock strengthening, and ultrasonic assisted processing. These technologies can effectively reduce the internal stress of the material without damaging the part structure, improving the dimensional stability and fatigue resistance of the part.

6. Optimize material selection

The tendency of work hardening and the plastic deformation capacity of different materials are different. Under the premise of meeting the performance requirements, it is advisable to choose materials with low work hardening tendency and good plasticity, which also helps to reduce stress accumulation during the processing process.

Conclusion

In summary, reducing processing stress in sheet metal processing is a systematic project that requires comprehensive consideration from multiple aspects such as design, technology, materials, and equipment. Through scientific and reasonable methods and means, not only can processing stress be effectively controlled, but the product quality and production efficiency can also be improved, extending the service life of the product, which has important practical significance and economic benefits.