News

How to reduce manual intervention in sheet metal manufacturing

Category:answer Publishing time:2025-10-04 11:23:41 Browse: Times

With the rapid development of the manufacturing industry and the continuous progress of automation technology, the sheet metal processing industry is gradually transforming towards intelligent and efficient directions. Traditional sheet metal processing processes heavily rely on manual operations, such as material handling, equipment adjustment, and quality inspection, which are not only inefficient but also prone to errors or safety hazards caused by human factors. Therefore, how to effectively reduce manual intervention and improve the level of production automation has become an important issue in the sheet metal manufacturing industry.

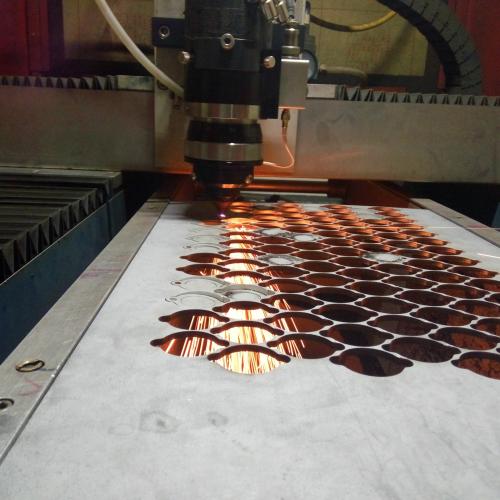

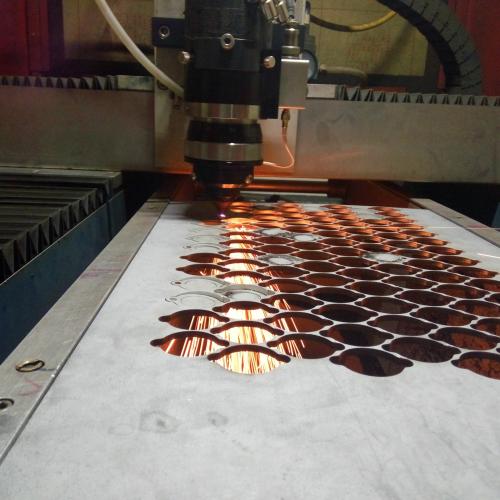

Firstly, introducing automated equipment is one of the key measures for reducing manual intervention. For example, the use of advanced equipment such as automatic feeding systems, robotic bending units, and laser cutting manipulators can achieve full-process automation from raw material feeding to processing completion. These equipment not only improves production efficiency but also significantly reduces dependence on skilled workers and reduces errors caused by manual operations.

Secondly, the application of intelligent manufacturing systems is also gradually changing the production mode of sheet metal manufacturing. Through MES (Manufacturing Execution System) and ERP (Enterprise Resource Planning) information management systems, enterprises can achieve real-time monitoring and optimization of production processes, equipment status, and material scheduling, thereby reducing the intermediate links involving manual participation and improving production transparency and management efficiency.

In addition, the development of intelligent detection technology also provides technical support for reducing manual intervention. Traditional quality inspection of sheet metal parts often relies on manual visual inspection and measurement, which is time-consuming and prone to errors. Now, based on machine vision, quality detection systems can automatically identify and judge parameters such as workpiece dimensions and surface defects, greatly improving detection efficiency and accuracy.

Moreover, strengthening employee training and equipment maintenance is also an important guarantee for promoting less labor-intensive production. Although automated equipment reduces the need for direct operators, it still requires engineers with certain technical capabilities for maintenance and technical support. Therefore, enterprises should strengthen the skill training of employees to enable them to operate and maintain automated equipment proficiently, ensuring the stable operation of the production process.

Finally, in the process of promoting the reduction of manual intervention, enterprises should also combine their own实际情况, reasonably plan the rhythm and scale of automation transformation, avoid blind investment, and ensure the maximization of investment return rate.

In summary, by introducing automated equipment, applying intelligent manufacturing systems, adopting intelligent detection methods, and strengthening personnel training, sheet metal manufacturing can significantly improve production efficiency and reduce manual intervention while ensuring product quality. In the future, with the further integration of cutting-edge technologies such as artificial intelligence and the Internet of Things, sheet metal manufacturing will continue to develop towards a more intelligent and efficient direction.

kkkkkkk

kkkkkkk

With the rapid development of the manufacturing industry and the continuous progress of automation technology, the sheet metal processing industry is gradually transforming towards intelligent and efficient directions. Traditional sheet metal processing processes heavily rely on manual operations, such as material handling, equipment adjustment, and quality inspection, which are not only inefficient but also prone to errors or safety hazards caused by human factors. Therefore, how to effectively reduce manual intervention and improve the level of production automation has become an important issue in the sheet metal manufacturing industry.

Firstly, introducing automated equipment is one of the key measures for reducing manual intervention. For example, the use of advanced equipment such as automatic feeding systems, robotic bending units, and laser cutting manipulators can achieve full-process automation from raw material feeding to processing completion. These equipment not only improves production efficiency but also significantly reduces dependence on skilled workers and reduces errors caused by manual operations.

Secondly, the application of intelligent manufacturing systems is also gradually changing the production mode of sheet metal manufacturing. Through MES (Manufacturing Execution System) and ERP (Enterprise Resource Planning) information management systems, enterprises can achieve real-time monitoring and optimization of production processes, equipment status, and material scheduling, thereby reducing the intermediate links involving manual participation and improving production transparency and management efficiency.

In addition, the development of intelligent detection technology also provides technical support for reducing manual intervention. Traditional quality inspection of sheet metal parts often relies on manual visual inspection and measurement, which is time-consuming and prone to errors. Now, based on machine vision, quality detection systems can automatically identify and judge parameters such as workpiece dimensions and surface defects, greatly improving detection efficiency and accuracy.

Moreover, strengthening employee training and equipment maintenance is also an important guarantee for promoting less labor-intensive production. Although automated equipment reduces the need for direct operators, it still requires engineers with certain technical capabilities for maintenance and technical support. Therefore, enterprises should strengthen the skill training of employees to enable them to operate and maintain automated equipment proficiently, ensuring the stable operation of the production process.

Finally, in the process of promoting the reduction of manual intervention, enterprises should also combine their own实际情况, reasonably plan the rhythm and scale of automation transformation, avoid blind investment, and ensure the maximization of investment return rate.

In summary, by introducing automated equipment, applying intelligent manufacturing systems, adopting intelligent detection methods, and strengthening personnel training, sheet metal manufacturing can significantly improve production efficiency and reduce manual intervention while ensuring product quality. In the future, with the further integration of cutting-edge technologies such as artificial intelligence and the Internet of Things, sheet metal manufacturing will continue to develop towards a more intelligent and efficient direction.

kkkkkkk

kkkkkkk