News

How to reduce handling loss in sheet metal manufacturing

Category:answer Publishing time:2025-11-03 19:32:18 Browse: Times

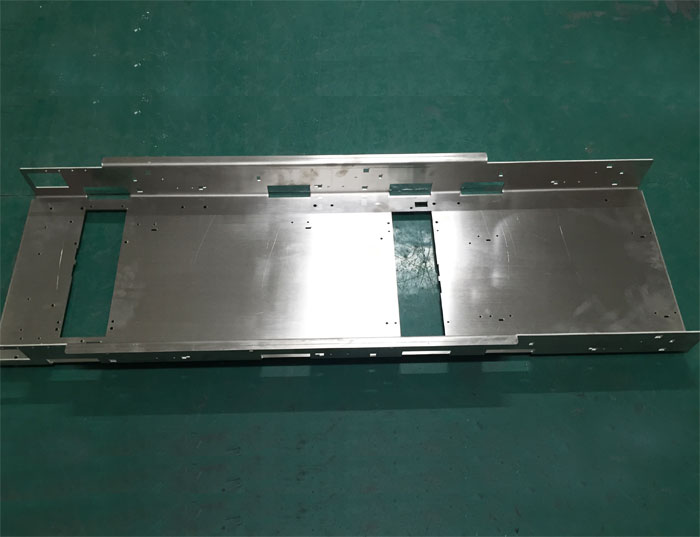

In the process of sheet metal manufacturing, handling is a seemingly simple but easily damaging link. Due to the thin, light, and easily deformed characteristics of sheet metal materials, improper handling often leads to surface scratches, deformation, or even scrapping, which in turn affects product quality and production efficiency, and increases enterprise costs. Therefore, in the sheet metal manufacturing industry, how to effectively reduce handling loss has become an important issue for improving overall management level.

Firstly, standardizing the handling process is the foundation for reducing loss. Enterprises should formulate detailed handling operation guidelines, specifying the operation specifications of each link, including loading, transportation, and stacking processes. For example, before handling, the fixed condition of the sheet metal parts should be checked to avoid collisions caused by loose fixation; during handling, avoid throwing or dragging at will to prevent scratches or deformation.

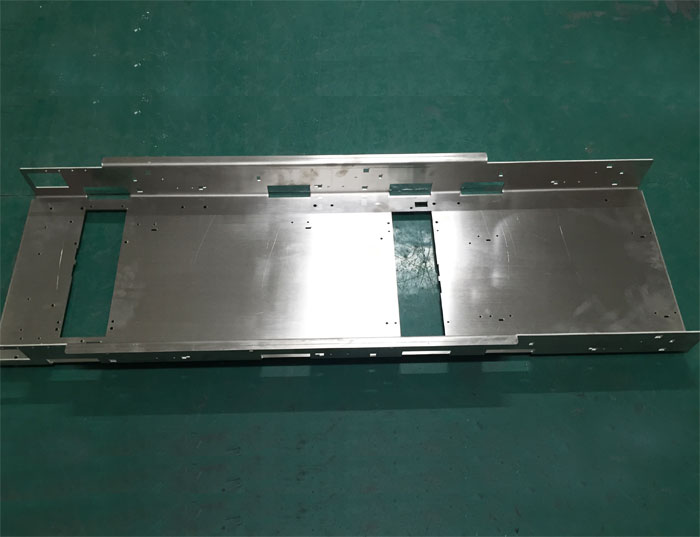

Secondly, the rational use of handling tools and equipment is vital. Traditional manual handling is prone to human errors, while using special handling equipment such as forklifts, hoists, and suction cup manipulators can not only improve work efficiency but also significantly reduce damage to sheet metal parts. Especially for large-area or easily deformed sheet metal parts, special tools or brackets should be used for support to prevent deformation due to gravity or external force during handling.

Thirdly, strengthening employee training and safety awareness is crucial. Front-line operators are key factors in the handling process. Regular training can improve employees' understanding of the characteristics of sheet metal materials, enabling them to master correct handling techniques such as gentle handling and avoiding stacking too high. At the same time, enhancing the sense of responsibility of employees makes them realize that handling loss not only affects product quality but also directly relates to the cost and benefit of the enterprise.

In addition, optimizing the storage and logistics layout also helps to reduce handling loss. Reasonably planning the storage area of materials allows sheet metal parts to be stored nearby before and after processing, reducing unnecessary long-distance transportation. At the same time, using special shelves and packaging materials for dust-proof, moisture-proof, and collision-proof can also effectively protect sheet metal parts from environmental influences.

Finally, introducing information management methods such as barcode recognition and RFID technology can enable the whole-process monitoring and traceability of the handling process of sheet metal parts, allowing for the timely discovery and correction of abnormal situations in the handling process, and controlling the loss from the source.

In summary, to reduce the loss in the handling process of sheet metal manufacturing, it is necessary to start from multiple aspects such as process specification, equipment investment, personnel training, storage layout, and information management. Only by establishing a scientific and reasonable handling management system can the goal of reducing loss, ensuring quality, and improving efficiency truly be achieved, laying a solid foundation for the sustainable development of the enterprise.

In the process of sheet metal manufacturing, handling is a seemingly simple but easily damaging link. Due to the thin, light, and easily deformed characteristics of sheet metal materials, improper handling often leads to surface scratches, deformation, or even scrapping, which in turn affects product quality and production efficiency, and increases enterprise costs. Therefore, in the sheet metal manufacturing industry, how to effectively reduce handling loss has become an important issue for improving overall management level.

Firstly, standardizing the handling process is the foundation for reducing loss. Enterprises should formulate detailed handling operation guidelines, specifying the operation specifications of each link, including loading, transportation, and stacking processes. For example, before handling, the fixed condition of the sheet metal parts should be checked to avoid collisions caused by loose fixation; during handling, avoid throwing or dragging at will to prevent scratches or deformation.

Secondly, the rational use of handling tools and equipment is vital. Traditional manual handling is prone to human errors, while using special handling equipment such as forklifts, hoists, and suction cup manipulators can not only improve work efficiency but also significantly reduce damage to sheet metal parts. Especially for large-area or easily deformed sheet metal parts, special tools or brackets should be used for support to prevent deformation due to gravity or external force during handling.

Thirdly, strengthening employee training and safety awareness is crucial. Front-line operators are key factors in the handling process. Regular training can improve employees' understanding of the characteristics of sheet metal materials, enabling them to master correct handling techniques such as gentle handling and avoiding stacking too high. At the same time, enhancing the sense of responsibility of employees makes them realize that handling loss not only affects product quality but also directly relates to the cost and benefit of the enterprise.

In addition, optimizing the storage and logistics layout also helps to reduce handling loss. Reasonably planning the storage area of materials allows sheet metal parts to be stored nearby before and after processing, reducing unnecessary long-distance transportation. At the same time, using special shelves and packaging materials for dust-proof, moisture-proof, and collision-proof can also effectively protect sheet metal parts from environmental influences.

Finally, introducing information management methods such as barcode recognition and RFID technology can enable the whole-process monitoring and traceability of the handling process of sheet metal parts, allowing for the timely discovery and correction of abnormal situations in the handling process, and controlling the loss from the source.

In summary, to reduce the loss in the handling process of sheet metal manufacturing, it is necessary to start from multiple aspects such as process specification, equipment investment, personnel training, storage layout, and information management. Only by establishing a scientific and reasonable handling management system can the goal of reducing loss, ensuring quality, and improving efficiency truly be achieved, laying a solid foundation for the sustainable development of the enterprise.