News

How to reduce debugging time in sheet metal processing

Category:answer Publishing time:2025-12-12 16:13:22 Browse: Times

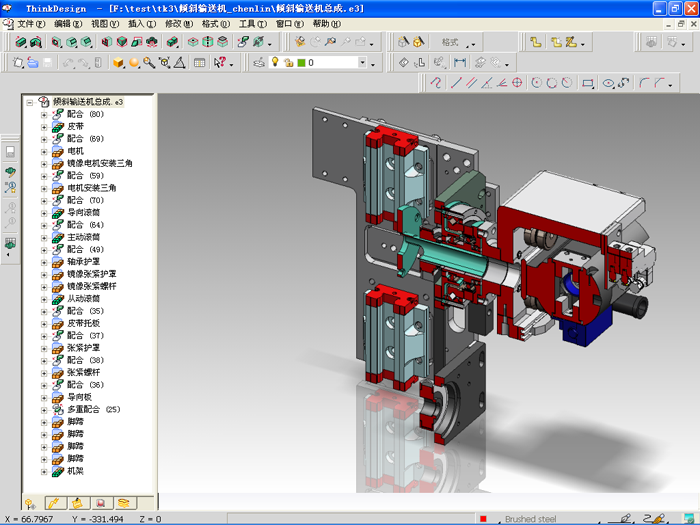

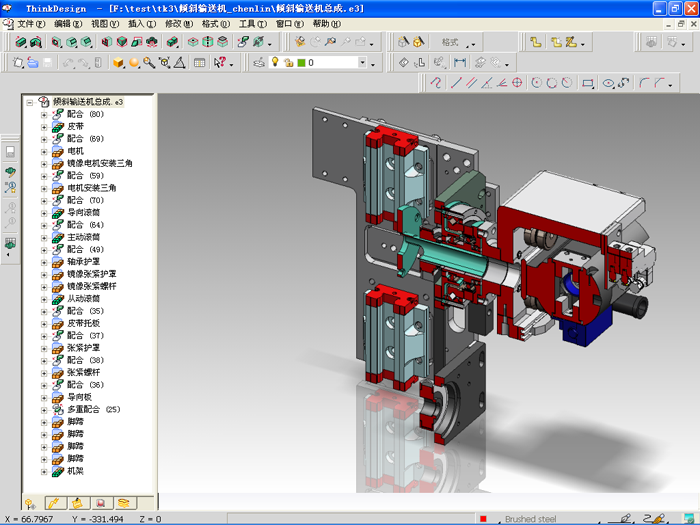

Firstly, optimizing design and process planning is the foundation for shortening debugging time. Whether the design of sheet metal parts is reasonable directly affects the complexity and difficulty of subsequent processing and debugging. Enterprises should closely collaborate with the manufacturing department at the product design stage and adopt the DFM (Design for Manufacturing) concept to ensure that the structure of the design is easy to process, easy to locate, and easy to clamp. In addition, with the help of CAD/CAM software for process simulation and path planning, potential problems can be discovered and adjusted in advance, thus reducing the trial-and-error cost in the actual debugging process.

Secondly, improving the level of equipment automation and intelligence is an effective means to reduce debugging time. For example, using advanced equipment such as press brakes with automatic mold change functions, laser cutting machines, and CNC bending machines can greatly shorten the time for mold change and parameter adjustment. At the same time, introducing intelligent control systems such as automatic positioning and automatic compensation functions can reduce manual intervention and improve the consistency and accuracy of debugging.

Furthermore, standardized operation processes and experience accumulation are crucial for shortening the debugging cycle. Enterprises should establish comprehensive debugging operation manuals and standard operating procedures (SOP), standardizing debugging steps and parameter settings. At the same time, encourage technical personnel to summarize debugging experience, form a case library or knowledge management system, which is convenient for new employees to quickly get started and can also quickly find solutions to similar problems when encountered.

Lastly, strengthening personnel training and team collaboration is also an indispensable part. The technical level and proficiency of operators directly affect the debugging efficiency. Regularly conducting skill training, equipment operation drills, and process knowledge learning can effectively enhance the overall quality of the team. In addition, strengthening inter-departmental communication and collaboration, such as information sharing between design, process, production, and quality, helps to quickly respond to problems in the debugging stage, reduce communication costs and rework time.

In summary, reducing debugging time in sheet metal processing requires efforts from multiple aspects such as design optimization, equipment upgrade, process standardization, and personnel training. Through systematic management and technological innovation, enterprises can not only improve production efficiency but also occupy a more advantageous position in the fierce market competition. In the future, with the continuous development of intelligent manufacturing technology, the debugging efficiency in the field of sheet metal processing is expected to achieve greater breakthroughs.

Firstly, optimizing design and process planning is the foundation for shortening debugging time. Whether the design of sheet metal parts is reasonable directly affects the complexity and difficulty of subsequent processing and debugging. Enterprises should closely collaborate with the manufacturing department at the product design stage and adopt the DFM (Design for Manufacturing) concept to ensure that the structure of the design is easy to process, easy to locate, and easy to clamp. In addition, with the help of CAD/CAM software for process simulation and path planning, potential problems can be discovered and adjusted in advance, thus reducing the trial-and-error cost in the actual debugging process.

Secondly, improving the level of equipment automation and intelligence is an effective means to reduce debugging time. For example, using advanced equipment such as press brakes with automatic mold change functions, laser cutting machines, and CNC bending machines can greatly shorten the time for mold change and parameter adjustment. At the same time, introducing intelligent control systems such as automatic positioning and automatic compensation functions can reduce manual intervention and improve the consistency and accuracy of debugging.

Furthermore, standardized operation processes and experience accumulation are crucial for shortening the debugging cycle. Enterprises should establish comprehensive debugging operation manuals and standard operating procedures (SOP), standardizing debugging steps and parameter settings. At the same time, encourage technical personnel to summarize debugging experience, form a case library or knowledge management system, which is convenient for new employees to quickly get started and can also quickly find solutions to similar problems when encountered.

Lastly, strengthening personnel training and team collaboration is also an indispensable part. The technical level and proficiency of operators directly affect the debugging efficiency. Regularly conducting skill training, equipment operation drills, and process knowledge learning can effectively enhance the overall quality of the team. In addition, strengthening inter-departmental communication and collaboration, such as information sharing between design, process, production, and quality, helps to quickly respond to problems in the debugging stage, reduce communication costs and rework time.

In summary, reducing debugging time in sheet metal processing requires efforts from multiple aspects such as design optimization, equipment upgrade, process standardization, and personnel training. Through systematic management and technological innovation, enterprises can not only improve production efficiency but also occupy a more advantageous position in the fierce market competition. In the future, with the continuous development of intelligent manufacturing technology, the debugging efficiency in the field of sheet metal processing is expected to achieve greater breakthroughs.