News

How to optimize the cooling method in sheet metal processing

Category:answer Publishing time:2025-10-14 20:49:04 Browse: Times

In the process of sheet metal processing, the reasonable selection and optimization of cooling methods have a significant impact on product quality, equipment life, and production efficiency. With the continuous advancement of processing technology, traditional cooling methods are no longer able to meet the production needs of high precision and high efficiency. Therefore, optimizing cooling methods has become one of the important means to improve the comprehensive performance of sheet metal processing.

Firstly, understanding the role of cooling in sheet metal processing is the premise of optimization. During the processing processes such as laser cutting, stamping, and welding, metal materials will produce a large amount of heat due to high temperature or friction. If the heat cannot be discharged in time, it may lead to workpiece deformation, a decrease in processing accuracy, or even equipment damage. Therefore, a reasonable cooling method not only helps to improve processing efficiency but also extends the service life of the equipment and ensures the quality of processing.

Currently, common cooling methods mainly include air cooling, water cooling, and oil cooling. Among them, air cooling has a simple structure and low cost, but low cooling efficiency, suitable for small equipment or low-power processing; water cooling systems have high cooling efficiency and are widely used in high-power laser cutting and other equipment, but they have high maintenance costs and are prone to scaling; oil cooling is suitable for high-precision processing equipment, which can provide a more stable cooling effect, but requires a large initial investment.

To optimize the cooling method, we should start from the following aspects:

1. Select the appropriate cooling type according to the process requirements

Different sheet metal processing technologies have different requirements for temperature control. For example, during the high-speed stamping process, it is recommended to prioritize air cooling or water cooling for rapid heat dissipation; while in high-precision laser cutting, it is suggested to use water cooling or oil cooling to maintain the stability and cutting accuracy of optical devices.

2. Introduce intelligent temperature control system

By introducing temperature sensors and automatic control systems, intelligent management of the cooling system is achieved. The system can automatically adjust the cooling intensity according to the temperature changes during the processing process, avoid energy waste, and ensure the stability of cooling effects.

3. Optimize cooling layout design

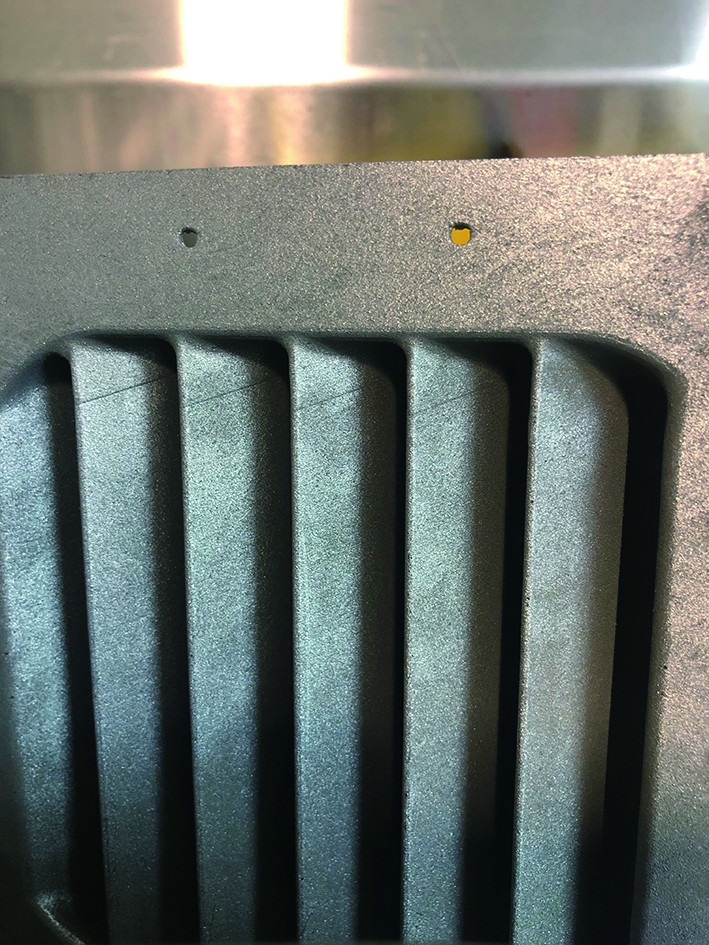

For large-scale sheet metal processing equipment, it is necessary to reasonably arrange cooling pipelines and heat dissipation openings to avoid local overheating. The use of modular cooling units can improve maintenance efficiency and provide precise cooling according to the heat load of different processing areas.

4. Promote environmentally friendly and energy-saving cooling media

Traditional coolants may pose pollution risks, and in the future, it should be promoted to use environmentally friendly coolants or gas cooling media, such as compressed air or inert gases, which can ensure cooling effects while reducing environmental pollution.

In summary, optimizing the cooling method in the process of sheet metal processing can not only improve processing efficiency and product accuracy, but also effectively reduce equipment wear and improve production safety. With the development of intelligent manufacturing and green manufacturing concepts, the future of sheet metal processing will continuously progress towards more efficient, intelligent, and environmentally friendly cooling directions. Enterprises should combine their own production characteristics, scientifically select and optimize cooling solutions, to cope with increasingly fierce market competition.

In the process of sheet metal processing, the reasonable selection and optimization of cooling methods have a significant impact on product quality, equipment life, and production efficiency. With the continuous advancement of processing technology, traditional cooling methods are no longer able to meet the production needs of high precision and high efficiency. Therefore, optimizing cooling methods has become one of the important means to improve the comprehensive performance of sheet metal processing.

Firstly, understanding the role of cooling in sheet metal processing is the premise of optimization. During the processing processes such as laser cutting, stamping, and welding, metal materials will produce a large amount of heat due to high temperature or friction. If the heat cannot be discharged in time, it may lead to workpiece deformation, a decrease in processing accuracy, or even equipment damage. Therefore, a reasonable cooling method not only helps to improve processing efficiency but also extends the service life of the equipment and ensures the quality of processing.

Currently, common cooling methods mainly include air cooling, water cooling, and oil cooling. Among them, air cooling has a simple structure and low cost, but low cooling efficiency, suitable for small equipment or low-power processing; water cooling systems have high cooling efficiency and are widely used in high-power laser cutting and other equipment, but they have high maintenance costs and are prone to scaling; oil cooling is suitable for high-precision processing equipment, which can provide a more stable cooling effect, but requires a large initial investment.

To optimize the cooling method, we should start from the following aspects:

1. Select the appropriate cooling type according to the process requirements

Different sheet metal processing technologies have different requirements for temperature control. For example, during the high-speed stamping process, it is recommended to prioritize air cooling or water cooling for rapid heat dissipation; while in high-precision laser cutting, it is suggested to use water cooling or oil cooling to maintain the stability and cutting accuracy of optical devices.

2. Introduce intelligent temperature control system

By introducing temperature sensors and automatic control systems, intelligent management of the cooling system is achieved. The system can automatically adjust the cooling intensity according to the temperature changes during the processing process, avoid energy waste, and ensure the stability of cooling effects.

3. Optimize cooling layout design

For large-scale sheet metal processing equipment, it is necessary to reasonably arrange cooling pipelines and heat dissipation openings to avoid local overheating. The use of modular cooling units can improve maintenance efficiency and provide precise cooling according to the heat load of different processing areas.

4. Promote environmentally friendly and energy-saving cooling media

Traditional coolants may pose pollution risks, and in the future, it should be promoted to use environmentally friendly coolants or gas cooling media, such as compressed air or inert gases, which can ensure cooling effects while reducing environmental pollution.

In summary, optimizing the cooling method in the process of sheet metal processing can not only improve processing efficiency and product accuracy, but also effectively reduce equipment wear and improve production safety. With the development of intelligent manufacturing and green manufacturing concepts, the future of sheet metal processing will continuously progress towards more efficient, intelligent, and environmentally friendly cooling directions. Enterprises should combine their own production characteristics, scientifically select and optimize cooling solutions, to cope with increasingly fierce market competition.