News

How to Optimize Production Layout in Sheet Metal Manufacturing

Category:answer Publishing time:2025-09-24 01:16:39 Browse: Times

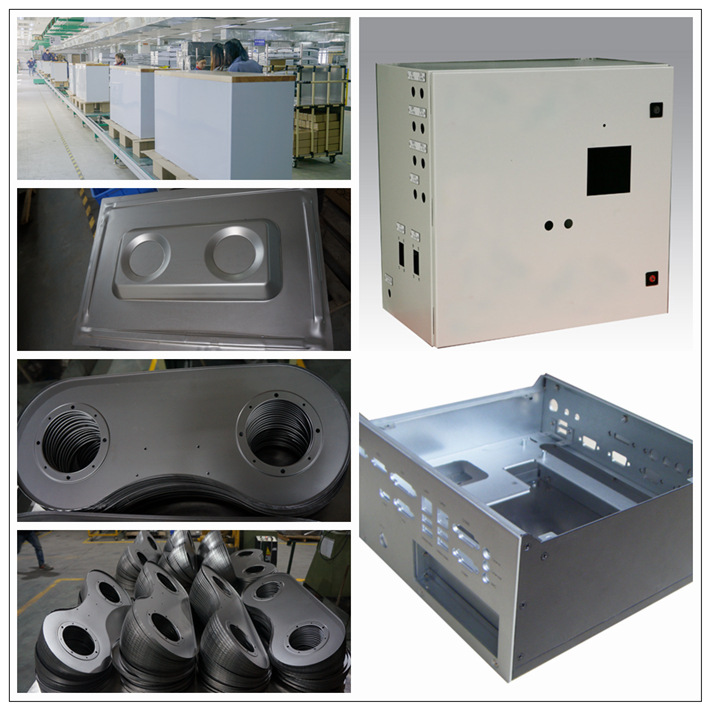

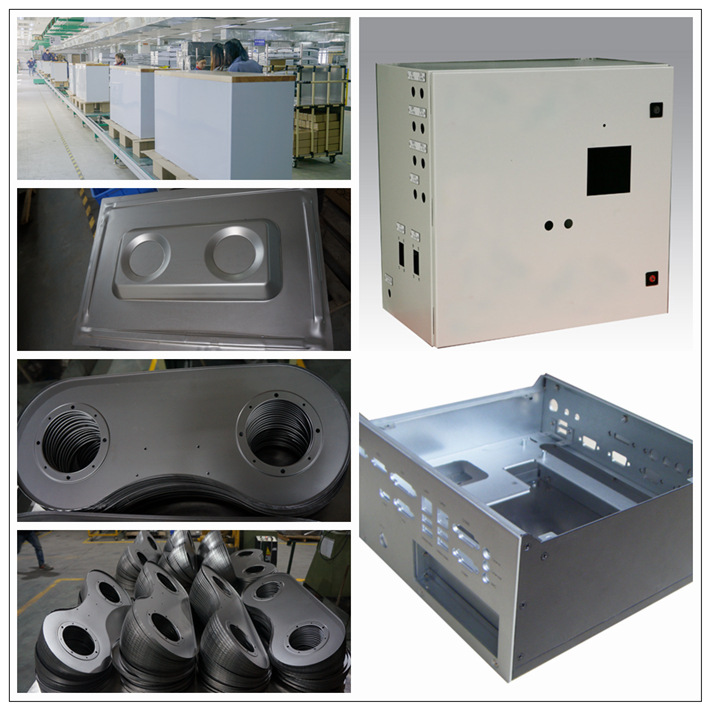

In modern manufacturing, sheet metal processing as an important production link is widely used in many fields such as automobiles, aerospace, electronic equipment, and construction machinery. With the intensification of market competition and the diversification of customer needs, how to improve efficiency, reduce costs, and enhance flexible production capacity through optimizing production layout has become an important issue that sheet metal manufacturing enterprises urgently need to solve.

The Significance of Optimizing Production Layout

The production layout is one of the key factors determining whether the production process runs smoothly. A reasonable workshop layout can effectively shorten the logistics path, reduce the accumulation of semi-finished products, improve equipment utilization rate and employee work efficiency, and at the same time, it is helpful to achieve lean production management. For sheet metal manufacturing, due to its complex process, a variety of equipment, frequent transportation of raw materials and finished products, scientific layout planning is even more necessary.

15. Main process flow and equipment distribution of sheet metal manufacturing

Sheet metal manufacturing generally includes multiple processes such as blanking, stamping, bending, welding, surface treatment, and assembly. Each process requires different equipment (such as laser cutting machines, stamping machines, bending machines, spot welding machines, etc.) for space, electricity, ventilation, and operation safety. Therefore, comprehensive consideration should be given to the联动 relationship between equipment, material flow paths, personnel flow, and storage space configuration when optimizing the layout.

13. Common layout methods and their advantages and disadvantages

12. Product-oriented layout: Suitable for sheet metal enterprises with large-scale, standardized production. Arrange the equipment required for similar products in sequence according to the process, which is conducive to improving production efficiency and automation level, but lacks flexibility and is difficult to adapt to the needs of multi-type small batch production.

11. Process-oriented layout: Concentrate similar process equipment together, suitable for scenarios of mixed-line production of various products, with strong flexibility but may lead to complex logistics and high handling costs.

10. Unitized layout (Cell Layout): Combine multiple related processes into an independent production unit, suitable for the production of sheet metal parts with various types and medium batch sizes. It helps to shorten the production cycle, reduce inventory of semi-finished products, and improve response speed.

9. U-shaped or circular layout: Suitable for assembly or bending processes with more manual participation, facilitating staff collaboration and material flow, and improving space utilization.

Four, Optimization strategies and suggestions

7. Process optimization based on value stream analysis: By identifying the value-added and non-value-added links in the production process, waste is eliminated, and the connection between each process is optimized.

6. Introduction of lean production concept: Adopting '5S' management, visual control, standardized operations, and other means to enhance on-site management level.

5. Rational planning of logistics paths: Ensure that the transportation paths of raw materials, semi-finished products, and finished products are the shortest and have no cross interference, avoiding congestion and waiting time.

4. Flexible equipment and space configuration: Reserve a certain amount of expansion space for future capacity adjustment or equipment upgrade.

3. Combination of digitalization and automation: Utilize MES, ERP systems to integrate information flow, and combine automated equipment such as AGV vehicles, robots for loading and unloading, etc., to improve layout efficiency and intelligent level.

Five, Conclusion

In summary, the optimization of production layout in the sheet metal manufacturing industry is a systematic project, involving various factors such as process flow, equipment configuration, logistics management, and personnel efficiency. Through scientific planning and continuous improvement, enterprises can not only enhance production efficiency and product quality but also strengthen market competitiveness. In the future, with the development of intelligent manufacturing, sheet metal manufacturing enterprises will have more innovative possibilities in layout optimization, achieving a higher level of intelligent, green, and efficient development.

In modern manufacturing, sheet metal processing as an important production link is widely used in many fields such as automobiles, aerospace, electronic equipment, and construction machinery. With the intensification of market competition and the diversification of customer needs, how to improve efficiency, reduce costs, and enhance flexible production capacity through optimizing production layout has become an important issue that sheet metal manufacturing enterprises urgently need to solve.

The Significance of Optimizing Production Layout

The production layout is one of the key factors determining whether the production process runs smoothly. A reasonable workshop layout can effectively shorten the logistics path, reduce the accumulation of semi-finished products, improve equipment utilization rate and employee work efficiency, and at the same time, it is helpful to achieve lean production management. For sheet metal manufacturing, due to its complex process, a variety of equipment, frequent transportation of raw materials and finished products, scientific layout planning is even more necessary.

15. Main process flow and equipment distribution of sheet metal manufacturing

Sheet metal manufacturing generally includes multiple processes such as blanking, stamping, bending, welding, surface treatment, and assembly. Each process requires different equipment (such as laser cutting machines, stamping machines, bending machines, spot welding machines, etc.) for space, electricity, ventilation, and operation safety. Therefore, comprehensive consideration should be given to the联动 relationship between equipment, material flow paths, personnel flow, and storage space configuration when optimizing the layout.

13. Common layout methods and their advantages and disadvantages

12. Product-oriented layout: Suitable for sheet metal enterprises with large-scale, standardized production. Arrange the equipment required for similar products in sequence according to the process, which is conducive to improving production efficiency and automation level, but lacks flexibility and is difficult to adapt to the needs of multi-type small batch production.

11. Process-oriented layout: Concentrate similar process equipment together, suitable for scenarios of mixed-line production of various products, with strong flexibility but may lead to complex logistics and high handling costs.

10. Unitized layout (Cell Layout): Combine multiple related processes into an independent production unit, suitable for the production of sheet metal parts with various types and medium batch sizes. It helps to shorten the production cycle, reduce inventory of semi-finished products, and improve response speed.

9. U-shaped or circular layout: Suitable for assembly or bending processes with more manual participation, facilitating staff collaboration and material flow, and improving space utilization.

Four, Optimization strategies and suggestions

7. Process optimization based on value stream analysis: By identifying the value-added and non-value-added links in the production process, waste is eliminated, and the connection between each process is optimized.

6. Introduction of lean production concept: Adopting '5S' management, visual control, standardized operations, and other means to enhance on-site management level.

5. Rational planning of logistics paths: Ensure that the transportation paths of raw materials, semi-finished products, and finished products are the shortest and have no cross interference, avoiding congestion and waiting time.

4. Flexible equipment and space configuration: Reserve a certain amount of expansion space for future capacity adjustment or equipment upgrade.

3. Combination of digitalization and automation: Utilize MES, ERP systems to integrate information flow, and combine automated equipment such as AGV vehicles, robots for loading and unloading, etc., to improve layout efficiency and intelligent level.

Five, Conclusion

In summary, the optimization of production layout in the sheet metal manufacturing industry is a systematic project, involving various factors such as process flow, equipment configuration, logistics management, and personnel efficiency. Through scientific planning and continuous improvement, enterprises can not only enhance production efficiency and product quality but also strengthen market competitiveness. In the future, with the development of intelligent manufacturing, sheet metal manufacturing enterprises will have more innovative possibilities in layout optimization, achieving a higher level of intelligent, green, and efficient development.