News

How to improve material utilization rate in sheet metal manufacturing

Category:answer Publishing time:2025-11-05 00:51:14 Browse: Times

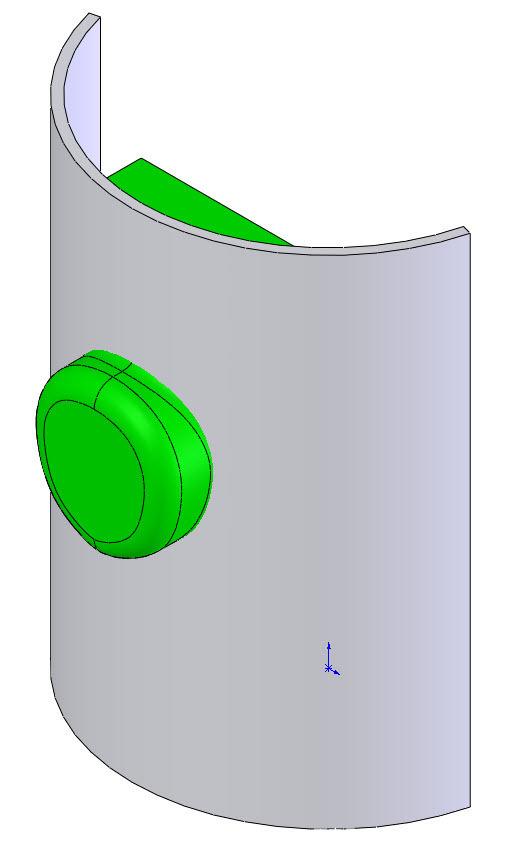

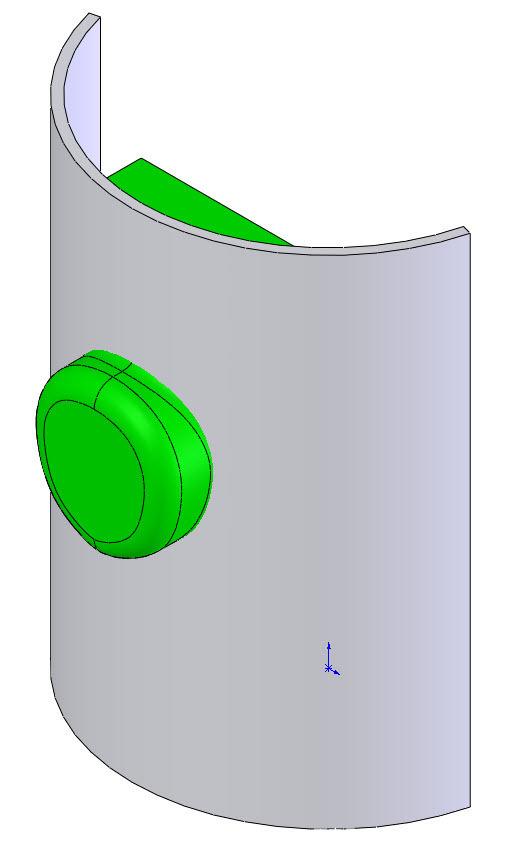

Firstly, optimizing product design is the key step to improve material utilization rate. In the design phase, engineers should fully consider the shape, size, and processing characteristics of materials, adopt modular and standardized design to reduce unnecessary structural complexity. At the same time, using computer-aided design (CAD) software for structural optimization can reduce the amount of material used without affecting performance.

Secondly, reasonable layout is the core means to improve material utilization rate. In the process of sheet metal cutting, the use of advanced nesting layout software can arrange multiple parts optimally on the sheet, to the greatest extent reducing the generation of scraps. Currently, many enterprises have introduced automatic layout systems, combined with advanced processes such as laser cutting and stamping, to achieve efficient and high-precision part processing, thereby significantly improving the utilization rate of raw materials.

Thirdly, improving processing technology and equipment is also an important way to increase material utilization rate. For example, the use of advanced laser cutting machines, CNC punch presses, and other equipment can achieve high-precision cutting, reducing the generation of waste. In addition, promoting the use of new cutting technologies such as co-edge cutting and bridge cutting can also save materials to a certain extent.

In addition, strengthening production management and process control cannot be ignored. By establishing a comprehensive material management system, fine management of raw materials can be achieved, avoiding waste caused by poor management. At the same time, strengthening the skill training of operation workers and improving their operation level and saving awareness also helps to reduce material loss caused by human factors.

Finally, promoting material recycling and reuse is also an effective way to achieve efficient resource utilization. The scraps and waste generated during the sheet metal manufacturing process should be sorted for recycling and cooperate with suppliers to realize the recycling or reprocessing of materials, thereby further reducing the overall material cost.

In summary, improving the material utilization rate in sheet metal manufacturing requires efforts from multiple aspects such as design optimization, layout technology, process improvement, production management, and material recycling. Only through systematic and scientific management methods can enterprises maintain a competitive edge in the fierce market competition and achieve the goals of green manufacturing and sustainable development at the same time.

Firstly, optimizing product design is the key step to improve material utilization rate. In the design phase, engineers should fully consider the shape, size, and processing characteristics of materials, adopt modular and standardized design to reduce unnecessary structural complexity. At the same time, using computer-aided design (CAD) software for structural optimization can reduce the amount of material used without affecting performance.

Secondly, reasonable layout is the core means to improve material utilization rate. In the process of sheet metal cutting, the use of advanced nesting layout software can arrange multiple parts optimally on the sheet, to the greatest extent reducing the generation of scraps. Currently, many enterprises have introduced automatic layout systems, combined with advanced processes such as laser cutting and stamping, to achieve efficient and high-precision part processing, thereby significantly improving the utilization rate of raw materials.

Thirdly, improving processing technology and equipment is also an important way to increase material utilization rate. For example, the use of advanced laser cutting machines, CNC punch presses, and other equipment can achieve high-precision cutting, reducing the generation of waste. In addition, promoting the use of new cutting technologies such as co-edge cutting and bridge cutting can also save materials to a certain extent.

In addition, strengthening production management and process control cannot be ignored. By establishing a comprehensive material management system, fine management of raw materials can be achieved, avoiding waste caused by poor management. At the same time, strengthening the skill training of operation workers and improving their operation level and saving awareness also helps to reduce material loss caused by human factors.

Finally, promoting material recycling and reuse is also an effective way to achieve efficient resource utilization. The scraps and waste generated during the sheet metal manufacturing process should be sorted for recycling and cooperate with suppliers to realize the recycling or reprocessing of materials, thereby further reducing the overall material cost.

In summary, improving the material utilization rate in sheet metal manufacturing requires efforts from multiple aspects such as design optimization, layout technology, process improvement, production management, and material recycling. Only through systematic and scientific management methods can enterprises maintain a competitive edge in the fierce market competition and achieve the goals of green manufacturing and sustainable development at the same time.