News

How to choose the tool magazine capacity of a machining center

Category:answer Publishing time:2025-10-24 03:17:01 Browse: Times

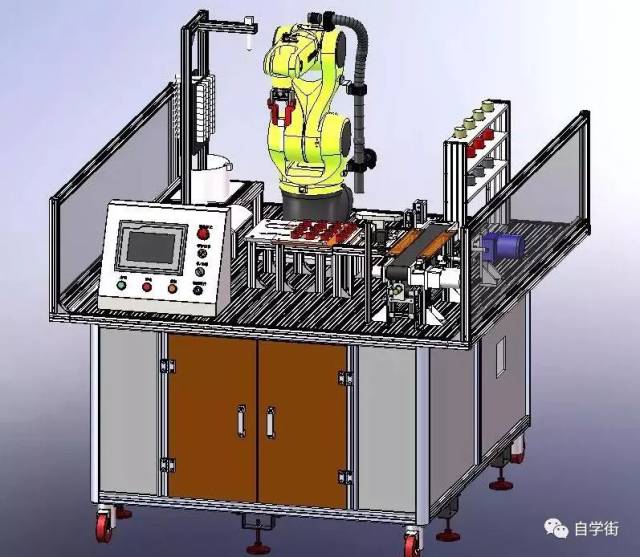

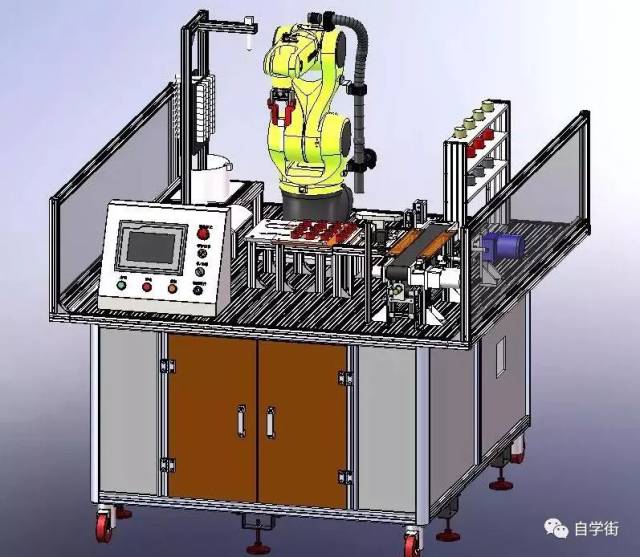

In modern manufacturing, the machining center (Machining Center) has become one of the key equipment for achieving high-efficiency and high-precision processing. Among the many configuration parameters of the machining center, the tool magazine capacity is a very critical selection factor. It not only directly affects the processing efficiency and automation level, but also is related to the investment cost of the equipment and the later expansion capability. Therefore, how to reasonably select the tool magazine capacity is particularly important when purchasing a machining center.

One, choose according to the complexity of the processing parts

The size of the tool magazine capacity directly affects the number of processing processes that can be completed in one clamping. For occasions where the processing parts are relatively simple and the number of tool types is small, such as processing tasks mainly involving milling, usually a tool capacity of about 24 sets is sufficient to meet the needs. For complex parts, especially those requiring multi-sided and multi-process combination processing, such as molds, box-type parts, etc., it may be necessary to frequently change different types of tools (such as drills, reamers, tapping tools, milling cutters, etc.), and in this case, a tool magazine with a larger capacity, such as 40, 60, or even more than 120 sets, should be chosen.

Two, consider the production volume and automation requirements

In mass production, the continuous operation capability and tool change efficiency of the equipment are crucial. A larger tool magazine can reduce the tool change time and avoid the efficiency loss caused by frequent shutdowns to change tools. In addition, if the enterprise has plans for automated production line layout, such as配合使用机械手、automatic loading and unloading system, it is recommended to choose products with larger tool magazine capacity and more stable structure to improve the degree of automation and flexibility of the entire line.

Three, balance the investment cost and usage efficiency of the equipment

Although large-capacity tool magazines can provide more processing freedom, their cost also increases accordingly, and may bring problems such as complex structure and increased maintenance difficulty. Therefore, comprehensive evaluation should be made when choosing, combining the current processing type, production tasks, and future development plan of the enterprise. For example, in the initial stage of small and medium-sized enterprises, it is advisable to prioritize medium-capacity tool magazines (such as 30-40 sets), which can meet most processing needs while avoiding resource waste; while for large-scale manufacturing enterprises or specialized processing plants, it is more suitable to configure large-capacity or chain-type tool magazines to meet diverse processing needs.

Four, pay attention to the matching of the tool magazine form and the tool change speed

In addition to capacity, the structural form of the tool magazine (such as disc type, chain type), the tool change speed, and the tool interface standard (such as BT, HSK) should also match the processing technology. For example, high-speed machining centers often adopt tool magazines with fast tool change speed and high stability, while heavy-duty cutting processing pays more attention to the carrying capacity and structural strength of the tools.

Conclusion

In summary, the selection of the tool magazine capacity of the machining center is not about the larger the better, but should be scientifically evaluated according to the actual processing requirements, the complexity of the parts, the production scale, and the level of automation. A reasonable configuration of the tool magazine capacity can not only improve the processing efficiency and equipment utilization rate, but also reduce the comprehensive operational cost of the enterprise while ensuring the quality of processing. Therefore, when purchasing a machining center, enterprises should fully investigate their own needs, combine the equipment performance and economy, and make the optimal choice.

In modern manufacturing, the machining center (Machining Center) has become one of the key equipment for achieving high-efficiency and high-precision processing. Among the many configuration parameters of the machining center, the tool magazine capacity is a very critical selection factor. It not only directly affects the processing efficiency and automation level, but also is related to the investment cost of the equipment and the later expansion capability. Therefore, how to reasonably select the tool magazine capacity is particularly important when purchasing a machining center.

One, choose according to the complexity of the processing parts

The size of the tool magazine capacity directly affects the number of processing processes that can be completed in one clamping. For occasions where the processing parts are relatively simple and the number of tool types is small, such as processing tasks mainly involving milling, usually a tool capacity of about 24 sets is sufficient to meet the needs. For complex parts, especially those requiring multi-sided and multi-process combination processing, such as molds, box-type parts, etc., it may be necessary to frequently change different types of tools (such as drills, reamers, tapping tools, milling cutters, etc.), and in this case, a tool magazine with a larger capacity, such as 40, 60, or even more than 120 sets, should be chosen.

Two, consider the production volume and automation requirements

In mass production, the continuous operation capability and tool change efficiency of the equipment are crucial. A larger tool magazine can reduce the tool change time and avoid the efficiency loss caused by frequent shutdowns to change tools. In addition, if the enterprise has plans for automated production line layout, such as配合使用机械手、automatic loading and unloading system, it is recommended to choose products with larger tool magazine capacity and more stable structure to improve the degree of automation and flexibility of the entire line.

Three, balance the investment cost and usage efficiency of the equipment

Although large-capacity tool magazines can provide more processing freedom, their cost also increases accordingly, and may bring problems such as complex structure and increased maintenance difficulty. Therefore, comprehensive evaluation should be made when choosing, combining the current processing type, production tasks, and future development plan of the enterprise. For example, in the initial stage of small and medium-sized enterprises, it is advisable to prioritize medium-capacity tool magazines (such as 30-40 sets), which can meet most processing needs while avoiding resource waste; while for large-scale manufacturing enterprises or specialized processing plants, it is more suitable to configure large-capacity or chain-type tool magazines to meet diverse processing needs.

Four, pay attention to the matching of the tool magazine form and the tool change speed

In addition to capacity, the structural form of the tool magazine (such as disc type, chain type), the tool change speed, and the tool interface standard (such as BT, HSK) should also match the processing technology. For example, high-speed machining centers often adopt tool magazines with fast tool change speed and high stability, while heavy-duty cutting processing pays more attention to the carrying capacity and structural strength of the tools.

Conclusion

In summary, the selection of the tool magazine capacity of the machining center is not about the larger the better, but should be scientifically evaluated according to the actual processing requirements, the complexity of the parts, the production scale, and the level of automation. A reasonable configuration of the tool magazine capacity can not only improve the processing efficiency and equipment utilization rate, but also reduce the comprehensive operational cost of the enterprise while ensuring the quality of processing. Therefore, when purchasing a machining center, enterprises should fully investigate their own needs, combine the equipment performance and economy, and make the optimal choice.