News

How to choose the tonnage of a stamping press

Category:answer Publishing time:2025-09-07 00:16:25 Browse: Times

Understanding the meaning of stamping press tonnage

The 'tonnage' of a stamping press refers to the maximum stamping force it can provide, measured in 'tons' (T) or 'kN'. For example, a 100-ton press indicates that its maximum stamping force is 100 tons of force. This parameter determines the thickness and hardness of the material that the press can process, as well as the types of stamping processes it can complete (such as punching, blanking, stretching, etc.).

The main factors affecting the tonnage selection of stamping presses

1. Properties of processed materials

Different materials require different stamping forces. For example, the force required for stamping stainless steel is greater than that for stamping low-carbon steel, while stamping aluminum requires less force. Therefore, it is first necessary to clarify the type, thickness, and tensile strength of the material to be processed.

2. Stamping process type

Different types of stamping processes have different requirements for stamping force. For example, the force required for punching and blanking is relatively small, while stretching or deep drawing processes require a larger tonnage. Usually, the tonnage required for stretching processes is 2~3 times that of punching processes with the same material.

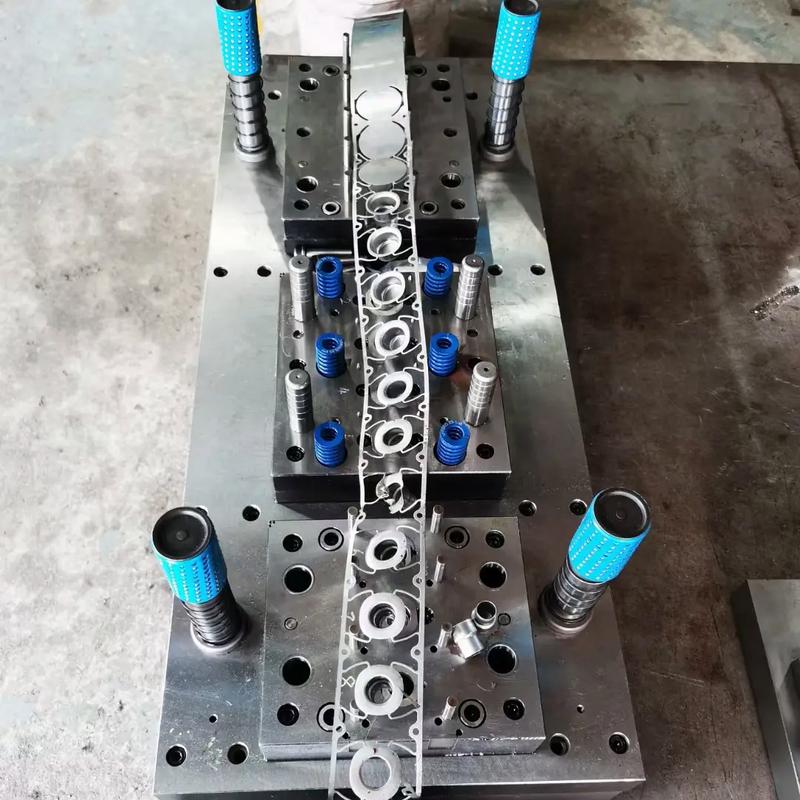

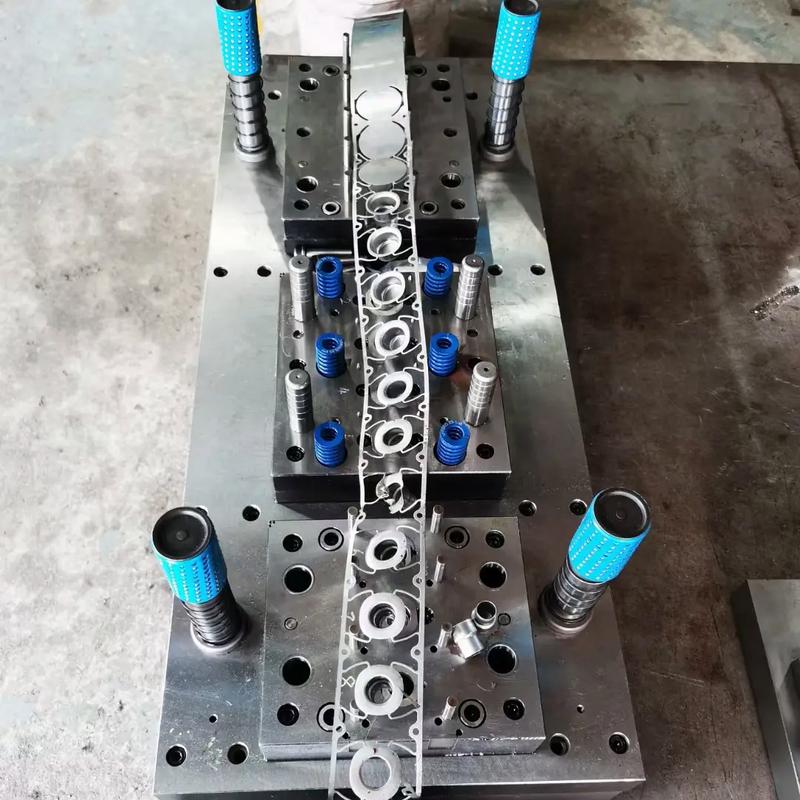

3. Mold structure and stamping area

The design of the mold directly affects the stamping area and the stress condition. The larger the stamping area, the higher the required stamping force. In addition, mold clearance, blade condition, and other factors will also affect the actual required tonnage.

4. Safety factor and future expansion needs

When calculating the required tonnage, it is appropriate to consider a safety factor (usually 1.2~1.5 times), to cope with unexpected situations or increased pressure from mold wear. At the same time, a certain tonnage reserve should also be left for future expansion of production scope.

III. Tonnage calculation method

The required tonnage of the press is generally estimated by the following formula:

$$

\text{Required tonnage (T)} = \frac{\text{Stamping circumference (mm)} × \text{Material thickness (mm)} × \text{Material shear strength (MPa)}}{9.8 × 1000}

$$

Among them:

- The stamping circumference refers to the contour length of the stamped part;

- The unit of material thickness is millimeters;

- Shear strength varies depending on the type of material, for example:

- Low-carbon steel is about 250~350 MPa;

- Stainless steel is about 400~600 MPa;

- Aluminum alloys are about 150~250 MPa.

Through this formula, a preliminary estimate of the required press tonnage can be made.

IV. Matters to be aware of in practical applications

1. Avoid excessively large or small tonnage

- An excessively small tonnage can result in incomplete stamping, accelerated mold wear, and even damage to the equipment;

- An excessively large tonnage leads to energy waste and increases the cost of purchase and operation.

2. Refer to equipment manufacturer recommendations

Most press manufacturers provide selection guides or technical support, which, combined with specific process requirements, are important references for purchasing.

3. Comprehensive consideration of automation needs

If automated production is planned, the compatibility of the press with the feeding system and mold change device also needs to be considered, which will also affect tonnage selection.

V. Conclusion

Choosing the appropriate press tonnage is the foundation for smooth production. Before purchasing a press, enterprises should fully understand their processing needs and, combined with material characteristics, process types, and mold design, conduct scientific and reasonable tonnage calculations. At the same time, it is recommended to communicate with professional technical personnel to obtain more accurate selection advice to ensure a perfect match between equipment performance and production needs. Only in this way can production efficiency be improved and operating costs reduced while ensuring product quality.

Understanding the meaning of stamping press tonnage

The 'tonnage' of a stamping press refers to the maximum stamping force it can provide, measured in 'tons' (T) or 'kN'. For example, a 100-ton press indicates that its maximum stamping force is 100 tons of force. This parameter determines the thickness and hardness of the material that the press can process, as well as the types of stamping processes it can complete (such as punching, blanking, stretching, etc.).

The main factors affecting the tonnage selection of stamping presses

1. Properties of processed materials

Different materials require different stamping forces. For example, the force required for stamping stainless steel is greater than that for stamping low-carbon steel, while stamping aluminum requires less force. Therefore, it is first necessary to clarify the type, thickness, and tensile strength of the material to be processed.

2. Stamping process type

Different types of stamping processes have different requirements for stamping force. For example, the force required for punching and blanking is relatively small, while stretching or deep drawing processes require a larger tonnage. Usually, the tonnage required for stretching processes is 2~3 times that of punching processes with the same material.

3. Mold structure and stamping area

The design of the mold directly affects the stamping area and the stress condition. The larger the stamping area, the higher the required stamping force. In addition, mold clearance, blade condition, and other factors will also affect the actual required tonnage.

4. Safety factor and future expansion needs

When calculating the required tonnage, it is appropriate to consider a safety factor (usually 1.2~1.5 times), to cope with unexpected situations or increased pressure from mold wear. At the same time, a certain tonnage reserve should also be left for future expansion of production scope.

III. Tonnage calculation method

The required tonnage of the press is generally estimated by the following formula:

$$

\text{Required tonnage (T)} = \frac{\text{Stamping circumference (mm)} × \text{Material thickness (mm)} × \text{Material shear strength (MPa)}}{9.8 × 1000}

$$

Among them:

- The stamping circumference refers to the contour length of the stamped part;

- The unit of material thickness is millimeters;

- Shear strength varies depending on the type of material, for example:

- Low-carbon steel is about 250~350 MPa;

- Stainless steel is about 400~600 MPa;

- Aluminum alloys are about 150~250 MPa.

Through this formula, a preliminary estimate of the required press tonnage can be made.

IV. Matters to be aware of in practical applications

1. Avoid excessively large or small tonnage

- An excessively small tonnage can result in incomplete stamping, accelerated mold wear, and even damage to the equipment;

- An excessively large tonnage leads to energy waste and increases the cost of purchase and operation.

2. Refer to equipment manufacturer recommendations

Most press manufacturers provide selection guides or technical support, which, combined with specific process requirements, are important references for purchasing.

3. Comprehensive consideration of automation needs

If automated production is planned, the compatibility of the press with the feeding system and mold change device also needs to be considered, which will also affect tonnage selection.

V. Conclusion

Choosing the appropriate press tonnage is the foundation for smooth production. Before purchasing a press, enterprises should fully understand their processing needs and, combined with material characteristics, process types, and mold design, conduct scientific and reasonable tonnage calculations. At the same time, it is recommended to communicate with professional technical personnel to obtain more accurate selection advice to ensure a perfect match between equipment performance and production needs. Only in this way can production efficiency be improved and operating costs reduced while ensuring product quality.