News

How to choose the process for surface treatment?

Category:answer Publishing time:2025-10-27 06:15:26 Browse: Times

In modern industrial manufacturing, surface treatment technology plays a crucial role in improving product performance, aesthetics, and extending service life. However, faced with a wide variety of surface treatment processes, how to choose the appropriate treatment method according to product characteristics and usage requirements has become an important issue for many enterprises.

I. Clarifying the Purpose of Surface Treatment

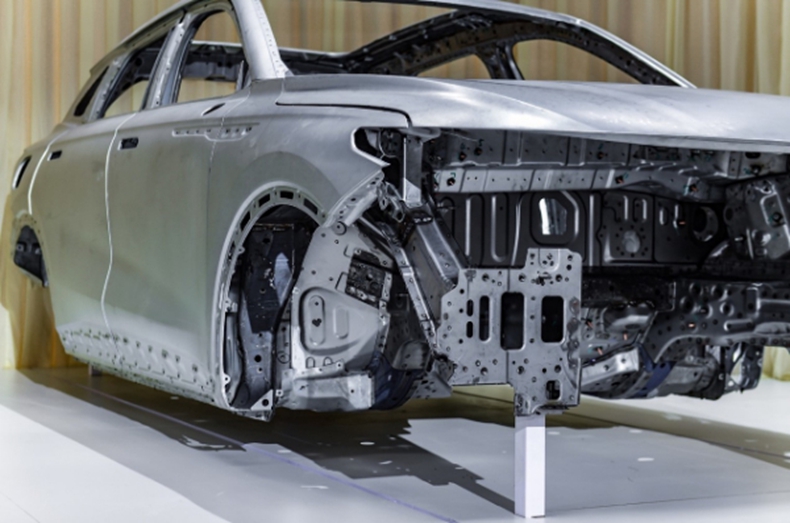

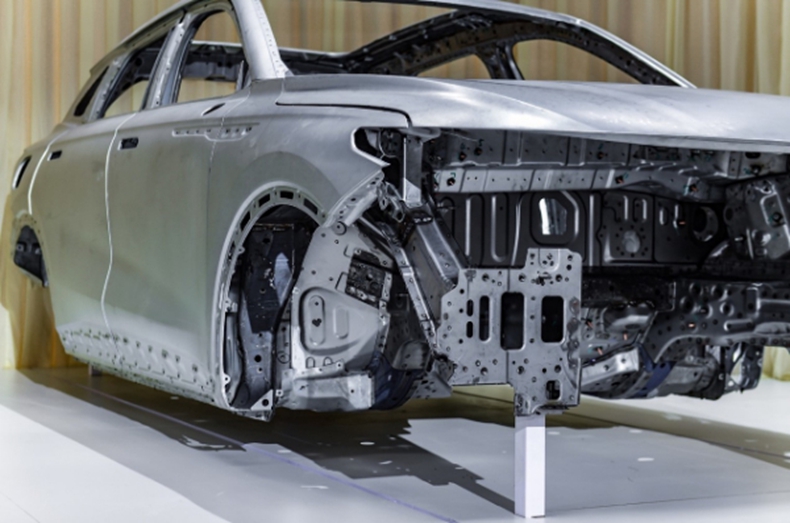

Before choosing a surface treatment process, it is first necessary to clarify the purpose of the treatment. Common treatment purposes include: improving material corrosion resistance, enhancing wear resistance, improving appearance, improving conductivity or insulation, and achieving specific functional coatings, etc. For example, automotive parts usually focus on corrosion resistance; while electronic components are more concerned about conductivity and welding performance.

II. Understanding Common Surface Treatment Processes

Currently common surface treatment processes include:

1. Electroplating (such as galvanizing, nickel plating, chrome plating): Suitable for surface protection and decoration of metals, with good corrosion resistance;

2. Anodizing: Mainly used for surface treatment of aluminum alloys, which can enhance wear resistance and corrosion resistance;

3. Spraying and Painting: Suitable for various materials such as metals and plastics, with good decorative effects;

4. Thermal Spraying: Suitable for applications requiring high wear resistance or high-temperature environments;

5. Chemical Plating: Suitable for non-conductive materials and complex-shaped parts;

6. Polishing and Wire Drawing: Used to enhance the luster and texture of the metal surface;

7. Passivation Treatment: Often used for stainless steel and galvanized layers to enhance their corrosion resistance.

III. Key Factors for Process Selection

9. Base Material Type: Different materials are suitable for different processes. For example, aluminum is suitable for anodizing, while steel parts are more suitable for electroplating or phosphating treatment.

8. Usage Environment: The working environment of the product determines the required protection level. For example, outdoor equipment needs to consider weather resistance, while marine environments emphasize anti-salt spray performance.

7. Cost Control: Some processes may have superior performance but high costs, so enterprises need to balance performance and cost.

6. Environmental Protection Requirements: With increasingly stringent environmental regulations, low-pollution and recyclable processes are becoming more favored. For example, water-based coatings, cyanide-free electroplating, and so on.

5. Process Feasibility: Includes factors such as processing cycle, equipment conditions, and process maturity.

IV. Case Study

Taking a certain outdoor metal structural component as an example, when choosing a surface treatment process, the first consideration is its long-term exposure to moisture and sunlight, therefore, it requires good anti-corrosion and weather resistance. Combined with carbon steel material, the final choice is to first galvanize and then apply a spray treatment, which ensures both the basic anti-corrosion performance and improves the appearance and weather resistance.

V. Conclusion

In summary, selecting an appropriate surface treatment process requires comprehensive consideration of various factors, not just the optimal performance of a single aspect. When enterprises are choosing a process, it is recommended to combine actual application needs, material characteristics, and cost-effectiveness. It is necessary to conduct small-scale sample verification if required, to ensure the quality and market competitiveness of the final product. Only by scientifically and reasonably selecting the surface treatment process can we truly achieve an overall improvement in product performance.

In modern industrial manufacturing, surface treatment technology plays a crucial role in improving product performance, aesthetics, and extending service life. However, faced with a wide variety of surface treatment processes, how to choose the appropriate treatment method according to product characteristics and usage requirements has become an important issue for many enterprises.

I. Clarifying the Purpose of Surface Treatment

Before choosing a surface treatment process, it is first necessary to clarify the purpose of the treatment. Common treatment purposes include: improving material corrosion resistance, enhancing wear resistance, improving appearance, improving conductivity or insulation, and achieving specific functional coatings, etc. For example, automotive parts usually focus on corrosion resistance; while electronic components are more concerned about conductivity and welding performance.

II. Understanding Common Surface Treatment Processes

Currently common surface treatment processes include:

1. Electroplating (such as galvanizing, nickel plating, chrome plating): Suitable for surface protection and decoration of metals, with good corrosion resistance;

2. Anodizing: Mainly used for surface treatment of aluminum alloys, which can enhance wear resistance and corrosion resistance;

3. Spraying and Painting: Suitable for various materials such as metals and plastics, with good decorative effects;

4. Thermal Spraying: Suitable for applications requiring high wear resistance or high-temperature environments;

5. Chemical Plating: Suitable for non-conductive materials and complex-shaped parts;

6. Polishing and Wire Drawing: Used to enhance the luster and texture of the metal surface;

7. Passivation Treatment: Often used for stainless steel and galvanized layers to enhance their corrosion resistance.

III. Key Factors for Process Selection

9. Base Material Type: Different materials are suitable for different processes. For example, aluminum is suitable for anodizing, while steel parts are more suitable for electroplating or phosphating treatment.

8. Usage Environment: The working environment of the product determines the required protection level. For example, outdoor equipment needs to consider weather resistance, while marine environments emphasize anti-salt spray performance.

7. Cost Control: Some processes may have superior performance but high costs, so enterprises need to balance performance and cost.

6. Environmental Protection Requirements: With increasingly stringent environmental regulations, low-pollution and recyclable processes are becoming more favored. For example, water-based coatings, cyanide-free electroplating, and so on.

5. Process Feasibility: Includes factors such as processing cycle, equipment conditions, and process maturity.

IV. Case Study

Taking a certain outdoor metal structural component as an example, when choosing a surface treatment process, the first consideration is its long-term exposure to moisture and sunlight, therefore, it requires good anti-corrosion and weather resistance. Combined with carbon steel material, the final choice is to first galvanize and then apply a spray treatment, which ensures both the basic anti-corrosion performance and improves the appearance and weather resistance.

V. Conclusion

In summary, selecting an appropriate surface treatment process requires comprehensive consideration of various factors, not just the optimal performance of a single aspect. When enterprises are choosing a process, it is recommended to combine actual application needs, material characteristics, and cost-effectiveness. It is necessary to conduct small-scale sample verification if required, to ensure the quality and market competitiveness of the final product. Only by scientifically and reasonably selecting the surface treatment process can we truly achieve an overall improvement in product performance.