News

How to avoid oxidation in plasma cutting

Category:answer Publishing time:2025-09-28 16:06:05 Browse: Times

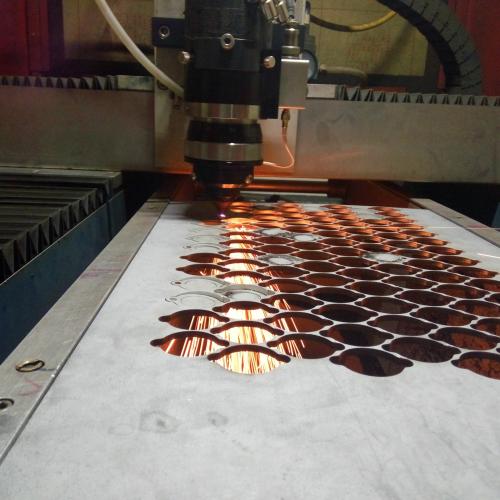

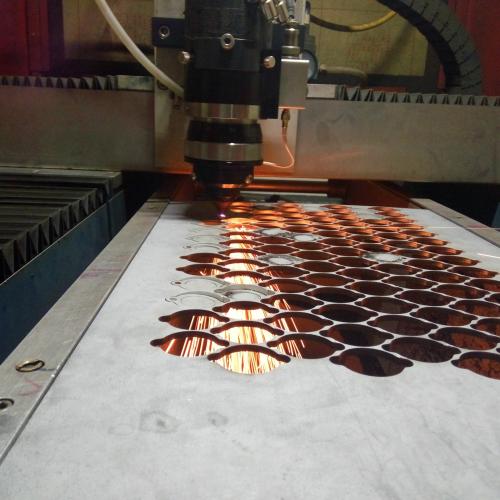

Plasma cutting is an efficient cutting technique widely used in the field of metal processing, especially suitable for the cutting of conductive materials such as carbon steel, stainless steel, and aluminum. However, during the cutting process, due to the action of high temperature and oxygen in the air, the metal surface is prone to oxidation, which affects the cutting quality and the subsequent processing effect. Therefore, how to effectively avoid oxidation problems during the plasma cutting process has become the key to improving the cutting quality.

I. Understanding the causes of oxidation

During the plasma cutting process, the high-temperature plasma arc heats the metal to the melting point and blows off the molten metal to achieve cutting. At the same time, oxygen in the air will react rapidly with the metal in the high-temperature environment, forming oxides, especially more obvious when cutting carbon steel and other easily oxidizable materials. The oxidation layer not only affects the appearance but also reduces the welding performance and increases the difficulty of subsequent processing.

II. Rational selection of gas medium

The type of gas used in plasma cutting has a direct impact on the degree of oxidation. Common cutting gases include compressed air, oxygen, nitrogen, argon, and their mixtures.

- Using oxygen as the cutting gas: Although it can improve cutting efficiency and cutting surface quality, it will also exacerbate oxidation reactions, forming a thicker oxidation layer.

- Using nitrogen or argon: These inert gases can effectively isolate oxygen, reduce oxidation phenomena, and are particularly suitable for materials sensitive to oxidation, such as stainless steel and aluminum alloy.

- Mixed gas: For example, a mixture of nitrogen and hydrogen can not only improve the cutting quality but also inhibit the occurrence of oxidation reactions.

Therefore, selecting the appropriate cutting gas according to the type of material and process requirements is an important means to avoid oxidation.

III. Controlling cutting parameters

Parameters such as cutting current, cutting speed, and nozzle height will also affect the degree of oxidation:

- Properly reducing the cutting current: High current will increase the temperature of the cutting area, aggravating the oxidation reaction.

- Maintaining an appropriate cutting speed: A slow cutting speed leads to heat concentration, increasing the possibility of oxidation; a fast speed may result in incomplete cutting.

- Adjusting the nozzle height: Keeping the nozzle at an appropriate distance from the workpiece surface helps the gas effectively cover the cutting area, reducing the participation of oxygen in the air in the reaction.

IV. Using protective gas assistance

In some high-precision or high-demand applications, additional protective gases (such as argon or carbon dioxide) can be introduced during plasma cutting to form a protective atmosphere in the cutting area, further isolating oxygen and reducing the occurrence of oxidation reactions.

V. Timely cleaning of the oxidation layer

Even with the above measures, it is still possible to form a slight oxidation layer at the cutting edge. After the cutting is completed, it should be timely removed using mechanical methods (such as grinding with sandpaper, polishing) or chemical methods (such as acid washing) to ensure the quality of subsequent processing.

Conclusion

In summary, to avoid oxidation during the plasma cutting process, it is necessary to start from multiple aspects such as gas selection, optimization of cutting parameters, and auxiliary protective measures. Through scientific and reasonable technical means, not only can the cutting quality be improved, but also the workload of subsequent processing can be reduced, and the overall processing efficiency can be increased. With the continuous progress of plasma cutting equipment and technology, in the future, there will also be more efficient and environmentally friendly solutions for inhibiting oxidation.

Plasma cutting is an efficient cutting technique widely used in the field of metal processing, especially suitable for the cutting of conductive materials such as carbon steel, stainless steel, and aluminum. However, during the cutting process, due to the action of high temperature and oxygen in the air, the metal surface is prone to oxidation, which affects the cutting quality and the subsequent processing effect. Therefore, how to effectively avoid oxidation problems during the plasma cutting process has become the key to improving the cutting quality.

I. Understanding the causes of oxidation

During the plasma cutting process, the high-temperature plasma arc heats the metal to the melting point and blows off the molten metal to achieve cutting. At the same time, oxygen in the air will react rapidly with the metal in the high-temperature environment, forming oxides, especially more obvious when cutting carbon steel and other easily oxidizable materials. The oxidation layer not only affects the appearance but also reduces the welding performance and increases the difficulty of subsequent processing.

II. Rational selection of gas medium

The type of gas used in plasma cutting has a direct impact on the degree of oxidation. Common cutting gases include compressed air, oxygen, nitrogen, argon, and their mixtures.

- Using oxygen as the cutting gas: Although it can improve cutting efficiency and cutting surface quality, it will also exacerbate oxidation reactions, forming a thicker oxidation layer.

- Using nitrogen or argon: These inert gases can effectively isolate oxygen, reduce oxidation phenomena, and are particularly suitable for materials sensitive to oxidation, such as stainless steel and aluminum alloy.

- Mixed gas: For example, a mixture of nitrogen and hydrogen can not only improve the cutting quality but also inhibit the occurrence of oxidation reactions.

Therefore, selecting the appropriate cutting gas according to the type of material and process requirements is an important means to avoid oxidation.

III. Controlling cutting parameters

Parameters such as cutting current, cutting speed, and nozzle height will also affect the degree of oxidation:

- Properly reducing the cutting current: High current will increase the temperature of the cutting area, aggravating the oxidation reaction.

- Maintaining an appropriate cutting speed: A slow cutting speed leads to heat concentration, increasing the possibility of oxidation; a fast speed may result in incomplete cutting.

- Adjusting the nozzle height: Keeping the nozzle at an appropriate distance from the workpiece surface helps the gas effectively cover the cutting area, reducing the participation of oxygen in the air in the reaction.

IV. Using protective gas assistance

In some high-precision or high-demand applications, additional protective gases (such as argon or carbon dioxide) can be introduced during plasma cutting to form a protective atmosphere in the cutting area, further isolating oxygen and reducing the occurrence of oxidation reactions.

V. Timely cleaning of the oxidation layer

Even with the above measures, it is still possible to form a slight oxidation layer at the cutting edge. After the cutting is completed, it should be timely removed using mechanical methods (such as grinding with sandpaper, polishing) or chemical methods (such as acid washing) to ensure the quality of subsequent processing.

Conclusion

In summary, to avoid oxidation during the plasma cutting process, it is necessary to start from multiple aspects such as gas selection, optimization of cutting parameters, and auxiliary protective measures. Through scientific and reasonable technical means, not only can the cutting quality be improved, but also the workload of subsequent processing can be reduced, and the overall processing efficiency can be increased. With the continuous progress of plasma cutting equipment and technology, in the future, there will also be more efficient and environmentally friendly solutions for inhibiting oxidation.