News

How to avoid delamination in aluminum-plastic plate sheet metal

Category:answer Publishing time:2025-09-20 00:15:15 Browse: Times

As a composite material widely used in architectural curtain walls, indoor and outdoor decoration, and industrial sheet metal processing, aluminum-plastic plates are favored for their light weight, aesthetics, and ease of processing. However, in the actual application process, aluminum-plastic plates often encounter the 'delamination' problem during processing, transportation, or installation, that is, the separation of the aluminum skin from the plastic core material, which seriously affects its structural performance and appearance quality. Therefore, how to effectively avoid the delamination phenomenon in the aluminum-plastic plate sheet metal process has become a problem that engineering and technical personnel must pay attention to.

Firstly, the reasons for delamination can mainly be analyzed from three aspects: the material itself, processing technology, and environmental factors. From the perspective of materials, the quality difference of aluminum-plastic plates is one of the main reasons for delamination. Poor-quality aluminum-plastic plates are prone to delamination during processing due to loose bonding layers or poor core material quality. In addition, if the aluminum-plastic plate is dampened during storage, it may also lead to a decrease in the bonding force between the core material and the aluminum skin.

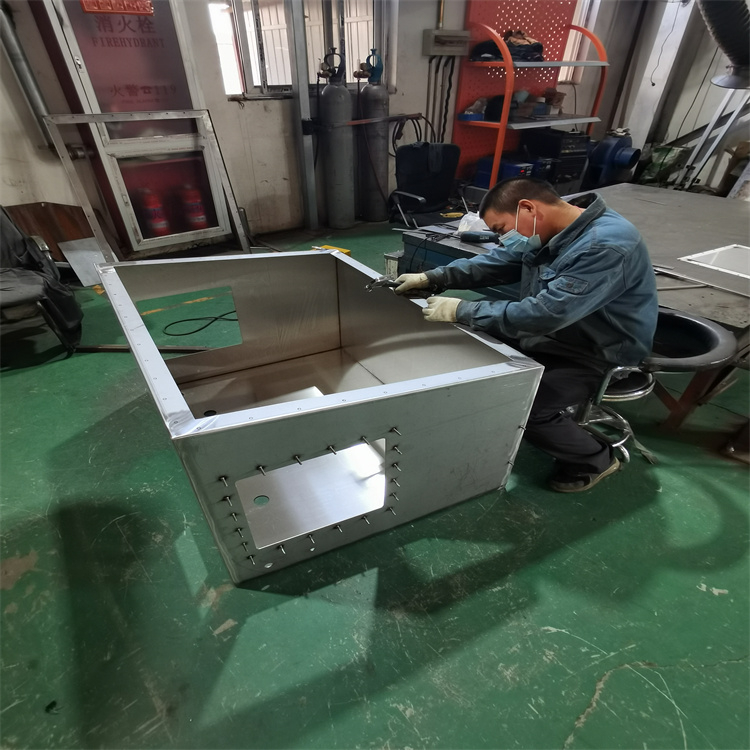

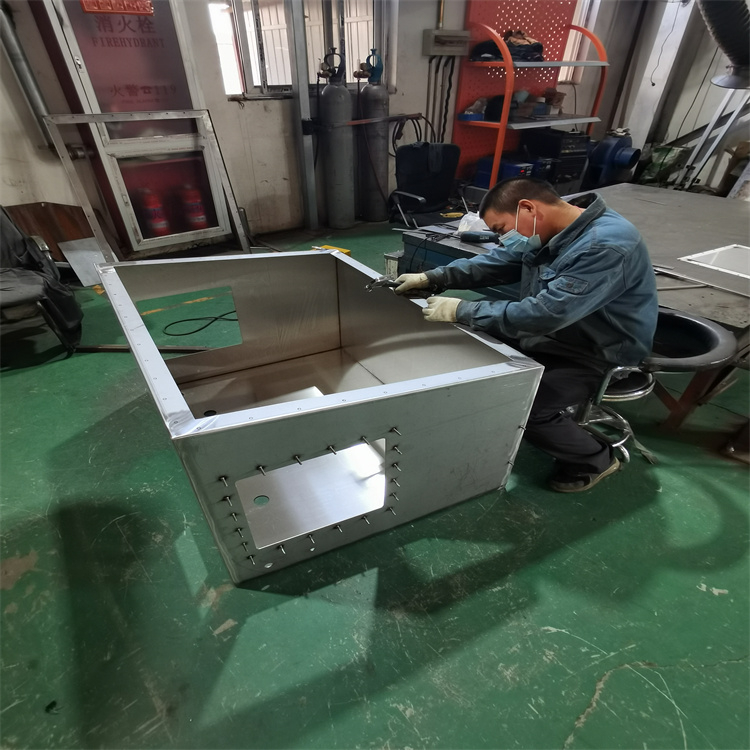

Secondly, in the sheet metal processing stage, improper operation is a common factor causing delamination. For example, a too small bending radius, excessive processing speed, and the use of unsuitable molds can all lead to excessive stress concentration on the aluminum-plastic plate during bending, thereby destroying the bonding between the aluminum skin and the core material. In addition, if the aluminum-plastic plate is dampened during storage, it may also lead to a decrease in the bonding force between the core material and the aluminum skin.

In order to effectively avoid the delamination problem of aluminum-plastic plates in sheet metal processing, we should start from the following aspects:

1. Select high-quality aluminum-plastic plate materials: Choosing aluminum-plastic plate products with excellent bonding performance and stable structure is the fundamental measure to prevent delamination. It is recommended to prioritize products produced by regular manufacturers and those with relevant certifications.

2. Reasonably design processing parameters: In processes such as bending and stamping, the minimum bending radius and processing speed should be reasonably set according to the specific model and thickness of the aluminum-plastic plate to avoid structural damage caused by excessive bending or stretching.

3. Optimize the processing technology methods: Cold processing methods are superior to hot processing methods. When hot processing is necessary, the temperature range should be strictly controlled to prevent overheating from affecting the material structure.

4. Strengthen protective measures during the processing: Pay attention to moisture-proof and collision-proof during transportation, storage, and processing to avoid delamination caused by external force damage or environmental changes.

5. Strengthen quality inspection and process training: Regularly conduct professional training for operators to enhance their understanding of the characteristics of aluminum-plastic plates and their operational skills, while strengthening the quality inspection of finished products to ensure that each process meets the standard.

kkkkkkk

kkkkkkk

In summary, in order to effectively avoid the delamination problem in the aluminum-plastic plate sheet metal process, it is necessary to consider multiple aspects such as material selection, processing technology, and operational specifications. Only by being rigorous and meticulous at every stage can the quality and performance of the final product be ensured, meeting the high standard requirements of engineering applications.

As a composite material widely used in architectural curtain walls, indoor and outdoor decoration, and industrial sheet metal processing, aluminum-plastic plates are favored for their light weight, aesthetics, and ease of processing. However, in the actual application process, aluminum-plastic plates often encounter the 'delamination' problem during processing, transportation, or installation, that is, the separation of the aluminum skin from the plastic core material, which seriously affects its structural performance and appearance quality. Therefore, how to effectively avoid the delamination phenomenon in the aluminum-plastic plate sheet metal process has become a problem that engineering and technical personnel must pay attention to.

Firstly, the reasons for delamination can mainly be analyzed from three aspects: the material itself, processing technology, and environmental factors. From the perspective of materials, the quality difference of aluminum-plastic plates is one of the main reasons for delamination. Poor-quality aluminum-plastic plates are prone to delamination during processing due to loose bonding layers or poor core material quality. In addition, if the aluminum-plastic plate is dampened during storage, it may also lead to a decrease in the bonding force between the core material and the aluminum skin.

Secondly, in the sheet metal processing stage, improper operation is a common factor causing delamination. For example, a too small bending radius, excessive processing speed, and the use of unsuitable molds can all lead to excessive stress concentration on the aluminum-plastic plate during bending, thereby destroying the bonding between the aluminum skin and the core material. In addition, if the aluminum-plastic plate is dampened during storage, it may also lead to a decrease in the bonding force between the core material and the aluminum skin.

In order to effectively avoid the delamination problem of aluminum-plastic plates in sheet metal processing, we should start from the following aspects:

1. Select high-quality aluminum-plastic plate materials: Choosing aluminum-plastic plate products with excellent bonding performance and stable structure is the fundamental measure to prevent delamination. It is recommended to prioritize products produced by regular manufacturers and those with relevant certifications.

2. Reasonably design processing parameters: In processes such as bending and stamping, the minimum bending radius and processing speed should be reasonably set according to the specific model and thickness of the aluminum-plastic plate to avoid structural damage caused by excessive bending or stretching.

3. Optimize the processing technology methods: Cold processing methods are superior to hot processing methods. When hot processing is necessary, the temperature range should be strictly controlled to prevent overheating from affecting the material structure.

4. Strengthen protective measures during the processing: Pay attention to moisture-proof and collision-proof during transportation, storage, and processing to avoid delamination caused by external force damage or environmental changes.

5. Strengthen quality inspection and process training: Regularly conduct professional training for operators to enhance their understanding of the characteristics of aluminum-plastic plates and their operational skills, while strengthening the quality inspection of finished products to ensure that each process meets the standard.

kkkkkkk

kkkkkkkIn summary, in order to effectively avoid the delamination problem in the aluminum-plastic plate sheet metal process, it is necessary to consider multiple aspects such as material selection, processing technology, and operational specifications. Only by being rigorous and meticulous at every stage can the quality and performance of the final product be ensured, meeting the high standard requirements of engineering applications.