News

How to reduce waste rate in sheet metal manufacturing

Category:answer Publishing time:2025-12-08 16:30:39 Browse: Times

In the sheet metal manufacturing industry, material cost is one of the important factors affecting enterprise profits. With the intensification of market competition and the continuous rise in raw material prices, how to effectively reduce waste rate and improve material utilization has become an important issue that sheet metal manufacturing enterprises must face and solve. This article will discuss effective strategies for reducing waste rate in sheet metal manufacturing from aspects such as design optimization, process improvement, equipment upgrading, and management enhancement.

First, optimize product design and improve material utilization

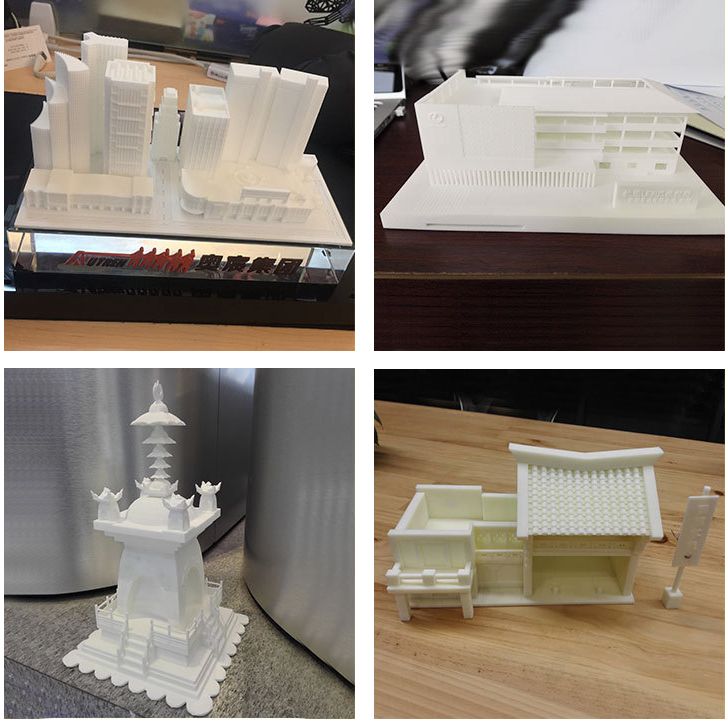

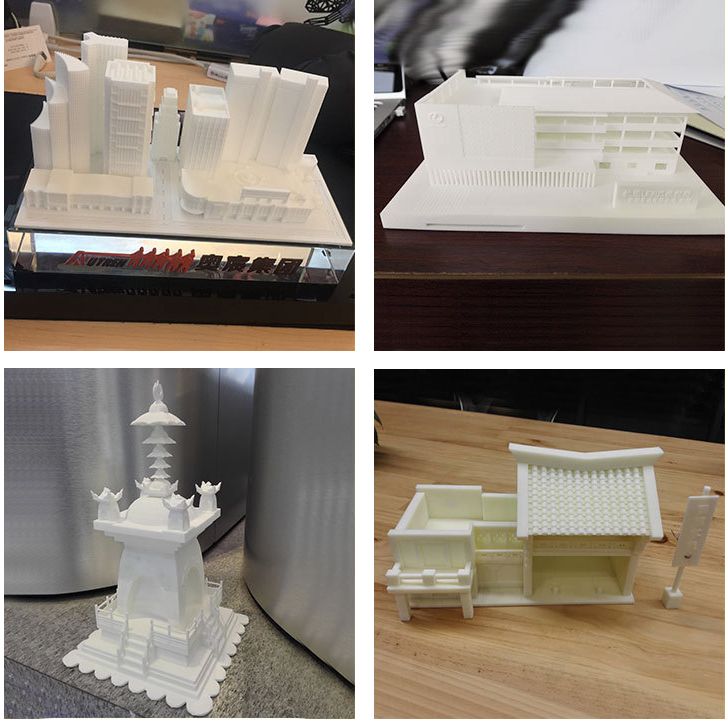

The design stage is a key link in determining the efficiency of material use. By adopting reasonable structural design and layout methods, material waste can be reduced at the source. For example, in product design, standardized and modular design is preferably used to facilitate the use of general molds and unified material specifications, thereby reducing additional losses caused by non-standard parts.

In addition, using advanced CAD/CAM software for part layout optimization can maximize the use of plate space and reduce the generation of waste materials. Especially in mass production, a good layout scheme can significantly improve material utilization and reduce unit cost.

Second, optimize the process flow and control processing loss

In the actual processing process, choosing appropriate processing technology and parameters is crucial for reducing waste. For example, reasonably selecting stamping, shearing, laser cutting, or water jet cutting, and choosing the best cutting path and process parameters according to the characteristics of different materials can effectively reduce burrs, deformation, and other quality problems, thereby reducing material waste caused by rework or scrapping.

At the same time, promoting the 'one-time molding' technology, reducing the number of process transitions, also helps to reduce material loss. In addition, the use of advanced processes such as progressive stamping and compound molds can also improve production efficiency and reduce the generation of waste materials.

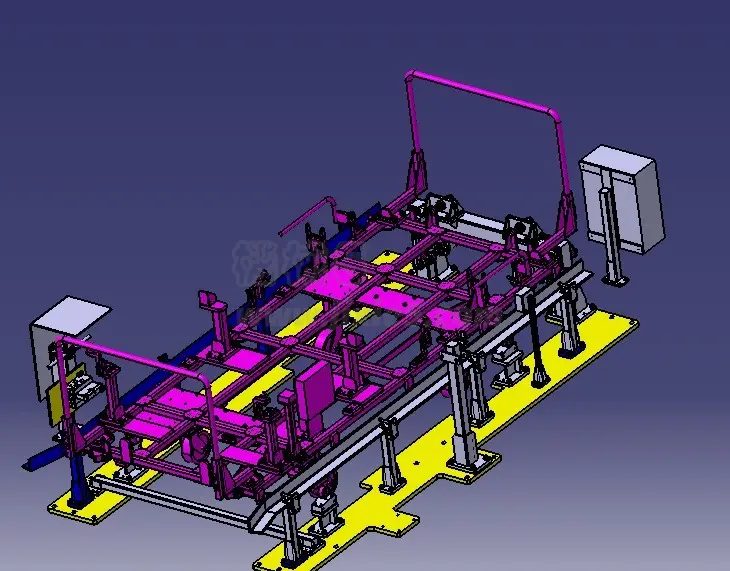

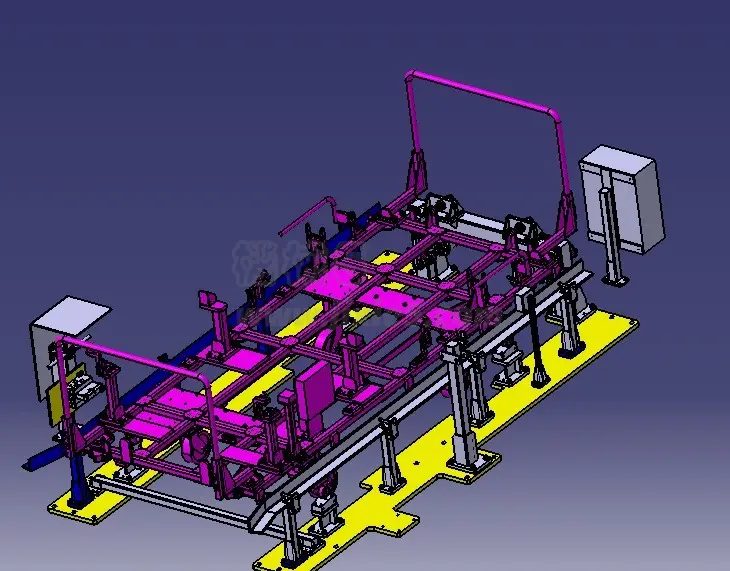

Third, introduce intelligent equipment to improve processing accuracy

Modern sheet metal manufacturing is increasingly dependent on automated and intelligent equipment. High-precision laser cutting machines, CNC punch presses, and automatic bending equipment can not only improve processing efficiency but also significantly improve processing accuracy, avoiding material waste caused by errors. For example, the use of intelligent material handling systems and automatic feeding devices can achieve efficient use of plates and minimize the generation of waste materials.

Fourth, strengthen production management and establish a cost control mechanism

Enterprises should establish a perfect material management system and cost control system. Through strict raw material procurement, inventory management, and production plan arrangement, avoid waste caused by material accumulation or misuse. At the same time, promote the lean production concept, track and analyze the source of waste in the production process, and discover and solve problems in a timely manner.

In addition, strengthening employee training and improving the technical level and awareness of operation personnel is also an indispensable part of reducing waste. The familiarity of front-line employees with equipment and technology directly affects the level of waste rate.

Conclusion

In summary, when facing fierce market competition, sheet metal manufacturing enterprises must start from multiple aspects such as design, technology, equipment, and management, comprehensively optimize the production process, improve material utilization rate, and effectively reduce waste rate. This not only helps to reduce costs and improve efficiency, but also is an important way to achieve green manufacturing and sustainable development.

In the sheet metal manufacturing industry, material cost is one of the important factors affecting enterprise profits. With the intensification of market competition and the continuous rise in raw material prices, how to effectively reduce waste rate and improve material utilization has become an important issue that sheet metal manufacturing enterprises must face and solve. This article will discuss effective strategies for reducing waste rate in sheet metal manufacturing from aspects such as design optimization, process improvement, equipment upgrading, and management enhancement.

First, optimize product design and improve material utilization

The design stage is a key link in determining the efficiency of material use. By adopting reasonable structural design and layout methods, material waste can be reduced at the source. For example, in product design, standardized and modular design is preferably used to facilitate the use of general molds and unified material specifications, thereby reducing additional losses caused by non-standard parts.

In addition, using advanced CAD/CAM software for part layout optimization can maximize the use of plate space and reduce the generation of waste materials. Especially in mass production, a good layout scheme can significantly improve material utilization and reduce unit cost.

Second, optimize the process flow and control processing loss

In the actual processing process, choosing appropriate processing technology and parameters is crucial for reducing waste. For example, reasonably selecting stamping, shearing, laser cutting, or water jet cutting, and choosing the best cutting path and process parameters according to the characteristics of different materials can effectively reduce burrs, deformation, and other quality problems, thereby reducing material waste caused by rework or scrapping.

At the same time, promoting the 'one-time molding' technology, reducing the number of process transitions, also helps to reduce material loss. In addition, the use of advanced processes such as progressive stamping and compound molds can also improve production efficiency and reduce the generation of waste materials.

Third, introduce intelligent equipment to improve processing accuracy

Modern sheet metal manufacturing is increasingly dependent on automated and intelligent equipment. High-precision laser cutting machines, CNC punch presses, and automatic bending equipment can not only improve processing efficiency but also significantly improve processing accuracy, avoiding material waste caused by errors. For example, the use of intelligent material handling systems and automatic feeding devices can achieve efficient use of plates and minimize the generation of waste materials.

Fourth, strengthen production management and establish a cost control mechanism

Enterprises should establish a perfect material management system and cost control system. Through strict raw material procurement, inventory management, and production plan arrangement, avoid waste caused by material accumulation or misuse. At the same time, promote the lean production concept, track and analyze the source of waste in the production process, and discover and solve problems in a timely manner.

In addition, strengthening employee training and improving the technical level and awareness of operation personnel is also an indispensable part of reducing waste. The familiarity of front-line employees with equipment and technology directly affects the level of waste rate.

Conclusion

In summary, when facing fierce market competition, sheet metal manufacturing enterprises must start from multiple aspects such as design, technology, equipment, and management, comprehensively optimize the production process, improve material utilization rate, and effectively reduce waste rate. This not only helps to reduce costs and improve efficiency, but also is an important way to achieve green manufacturing and sustainable development.