News

How to reduce vibration in cutting processing

Category:answer Publishing time:2025-12-14 00:47:05 Browse: Times

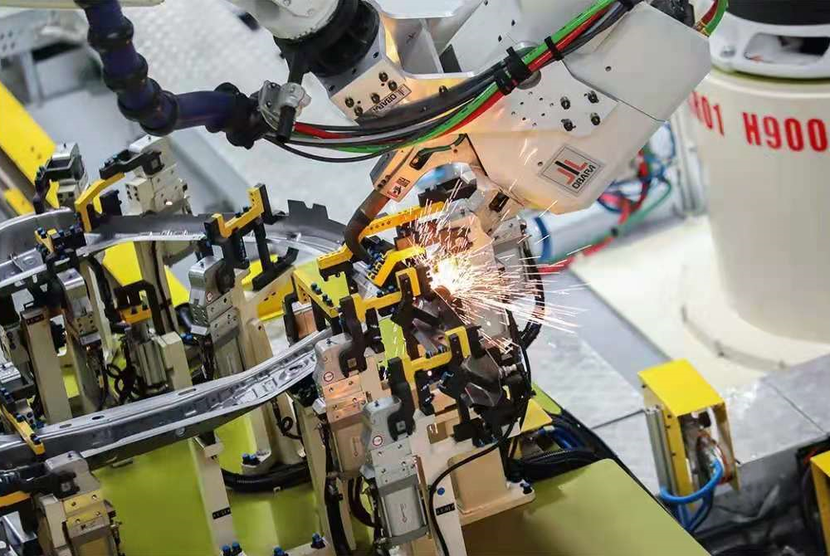

Planer machining is a common metal cutting process widely used in the fields of mechanical manufacturing and maintenance. However, during the planer cutting process, vibration is often caused by various factors, which not only affects the quality of the machining surface but also reduces the service life of the tool and even causes damage to the machine tool. Therefore, studying and mastering the methods to reduce planer vibration is of great significance for improving processing efficiency and product quality.

One, The causes of planer vibration

During the planer cutting process, vibration mainly comes from three aspects: insufficient rigidity of the machine tool system, changes in cutting force between the tool and the workpiece, and unstable workpiece clamping. In addition, tool wear, improper selection of cutting parameters, and excessive guide rail gap will also exacerbate the vibration phenomenon.

Two, Specific measures to reduce vibration

1. Improve the stability of the machine tool and fixture

The rigidity and stability of the machine tool are key factors affecting vibration. Regularly check the fastening status of each part of the machine tool, especially the gap between the guide rail surface and sliding surface, to avoid resonance caused by loosening. The fixture should be selected with good rigidity and uniform clamping force to ensure that the workpiece does not displace or loosen during the machining process.

2. Select cutting parameters reasonably

Cutting speed, feed rate, and cutting depth have a direct impact on vibration. Generally, excessive cutting speed or large cutting depth will exacerbate vibration. Cutting parameters should be set reasonably according to the workpiece material, tool material, and machine tool performance, and medium cutting speed with a smaller feed rate should be prioritized to reduce cutting impact force.

3. Optimize tool structure and angles

The geometric shape of the tool is crucial for vibration control. Choosing tools with appropriate anterior angle, posterior angle, and main cutting edge can effectively reduce cutting resistance. At the same time, using tools with chip-breaking grooves can make the chips easier to break, reducing the unstable factors in the cutting process.

4. Adopt vibration damping devices or materials

Using vibration-damping pads or installing vibration dampers on the machine tool worktable can absorb part of the vibration energy; filling damping materials (such as polymers or heavy metal damping materials) inside the tool shank can also effectively suppress the self-excited vibration of the tool.

5. Improve the rigidity of workpiece clamping

The workpiece clamping should be as close as possible to the machining part to reduce the overhang length. For slender workpieces, auxiliary support can be provided by using a center support or a follow-up support, thereby improving the overall rigidity and reducing vibration problems caused by insufficient rigidity.

6. Regular maintenance and monitoring

Regularly inspect the operating status of the machine tool spindle, guide rail, and transmission system, and replace worn parts in time to maintain the good working condition of the machine tool. It is also possible to grasp the vibration situation in real time through vibration monitoring equipment, and discover and deal with potential problems in advance.

Three, Conclusion

Reducing vibration in planer machining is a systematic project that requires comprehensive consideration from multiple aspects such as machine tool structure, tool selection, cutting parameter setting, and clamping methods. Only through scientific and reasonable technical means can vibration be effectively controlled, improve processing quality and efficiency, and extend the service life of equipment. With the development of numerical control technology, the application of intelligent control and real-time feedback in the future will also provide more accurate and efficient solutions for reducing planer vibration.

Planer machining is a common metal cutting process widely used in the fields of mechanical manufacturing and maintenance. However, during the planer cutting process, vibration is often caused by various factors, which not only affects the quality of the machining surface but also reduces the service life of the tool and even causes damage to the machine tool. Therefore, studying and mastering the methods to reduce planer vibration is of great significance for improving processing efficiency and product quality.

One, The causes of planer vibration

During the planer cutting process, vibration mainly comes from three aspects: insufficient rigidity of the machine tool system, changes in cutting force between the tool and the workpiece, and unstable workpiece clamping. In addition, tool wear, improper selection of cutting parameters, and excessive guide rail gap will also exacerbate the vibration phenomenon.

Two, Specific measures to reduce vibration

1. Improve the stability of the machine tool and fixture

The rigidity and stability of the machine tool are key factors affecting vibration. Regularly check the fastening status of each part of the machine tool, especially the gap between the guide rail surface and sliding surface, to avoid resonance caused by loosening. The fixture should be selected with good rigidity and uniform clamping force to ensure that the workpiece does not displace or loosen during the machining process.

2. Select cutting parameters reasonably

Cutting speed, feed rate, and cutting depth have a direct impact on vibration. Generally, excessive cutting speed or large cutting depth will exacerbate vibration. Cutting parameters should be set reasonably according to the workpiece material, tool material, and machine tool performance, and medium cutting speed with a smaller feed rate should be prioritized to reduce cutting impact force.

3. Optimize tool structure and angles

The geometric shape of the tool is crucial for vibration control. Choosing tools with appropriate anterior angle, posterior angle, and main cutting edge can effectively reduce cutting resistance. At the same time, using tools with chip-breaking grooves can make the chips easier to break, reducing the unstable factors in the cutting process.

4. Adopt vibration damping devices or materials

Using vibration-damping pads or installing vibration dampers on the machine tool worktable can absorb part of the vibration energy; filling damping materials (such as polymers or heavy metal damping materials) inside the tool shank can also effectively suppress the self-excited vibration of the tool.

5. Improve the rigidity of workpiece clamping

The workpiece clamping should be as close as possible to the machining part to reduce the overhang length. For slender workpieces, auxiliary support can be provided by using a center support or a follow-up support, thereby improving the overall rigidity and reducing vibration problems caused by insufficient rigidity.

6. Regular maintenance and monitoring

Regularly inspect the operating status of the machine tool spindle, guide rail, and transmission system, and replace worn parts in time to maintain the good working condition of the machine tool. It is also possible to grasp the vibration situation in real time through vibration monitoring equipment, and discover and deal with potential problems in advance.

Three, Conclusion

Reducing vibration in planer machining is a systematic project that requires comprehensive consideration from multiple aspects such as machine tool structure, tool selection, cutting parameter setting, and clamping methods. Only through scientific and reasonable technical means can vibration be effectively controlled, improve processing quality and efficiency, and extend the service life of equipment. With the development of numerical control technology, the application of intelligent control and real-time feedback in the future will also provide more accurate and efficient solutions for reducing planer vibration.