News

How to reduce the time for tool change in sheet metal processing

Category:answer Publishing time:2025-11-16 06:04:54 Browse: Times

In the sheet metal processing industry, the time for tool change is one of the important factors affecting production efficiency and equipment utilization. With the intensification of market competition, enterprises have higher and higher requirements for production rhythm. How to minimize the time for tool change while ensuring processing quality has become a key link to improve overall production efficiency. This article will discuss how to effectively reduce the time for tool change in sheet metal processing from three aspects: equipment optimization, process improvement, and personnel management.

I. Optimize Equipment Configuration and Tool Change System

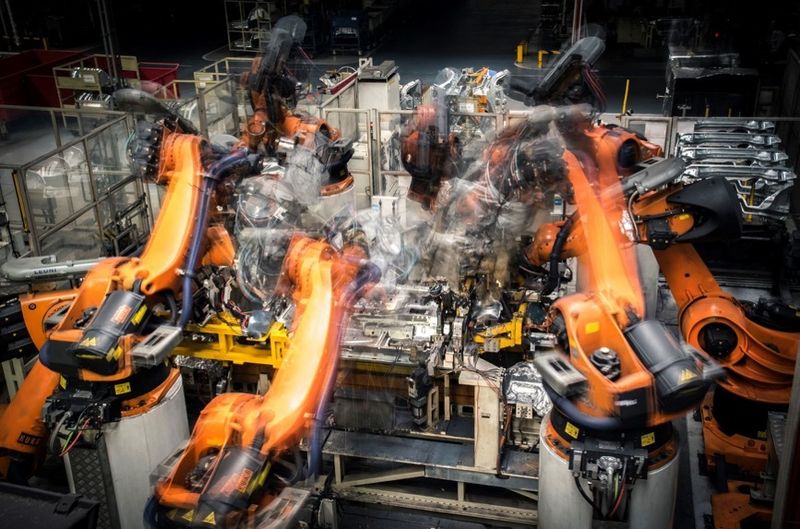

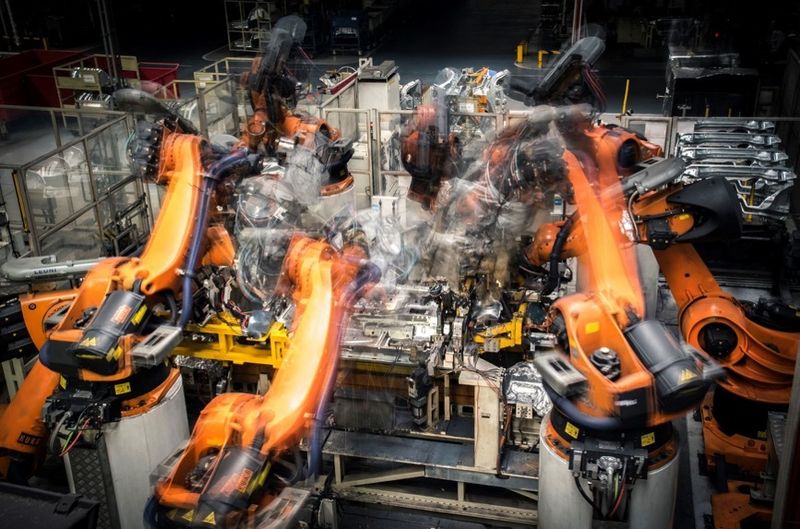

Modern sheet metal processing equipment such as presses, laser cutting machines, and bending machines are usually equipped with automatic tool change systems (ATC), but their efficiency still depends on the rationality of tool configuration. Enterprises should reasonably plan the types and quantities of tools in the tool library according to common processing technologies and product types, and avoid repeated or redundant configurations. At the same time, the use of modular tools and standardized interface design can also significantly improve the speed of tool change.

In addition, regular maintenance and maintenance of the tool change system should be carried out to ensure the normal operation of the robotic arm, pneumatic components, and sensors, and to avoid prolonged unplanned downtime due to equipment failure.

II. Optimize Processing Technology and Programming

In the stage of process design, it is advisable to adopt multi-process integrated processing methods as much as possible to reduce unnecessary repeated tool change operations. For example, in the laser cutting process, reasonable layout of cutting paths can achieve the processing of multiple parts in one clamping; in press forming processing, by reasonably arranging the mold sequence, the number of mold changes can be minimized as much as possible.

Using advanced CAM software for intelligent programming can also achieve automatic optimization of tool paths, reduce unnecessary travel, and improve the efficiency of work connection before and after tool change. At the same time, establishing a processing template library for typical parts can help quickly call up mature processes and shorten preparation time.

III. Strengthen Personnel Training and Standardized Management

The skillfulness of personnel operation directly affects the actual time for tool change. Therefore, enterprises should provide systematic skill training for operators, enabling them to be familiar with the equipment operation process, tool change steps, and common problem-solving methods. Implementing standardized operating procedures (SOP) helps to decompose and control the time of the tool change process, which is conducive to reducing delays caused by human factors.

In addition, establishing a performance evaluation mechanism and incorporating the time for tool change into the production assessment system can motivate employees to continuously improve operational efficiency and foster a culture of continuous improvement.

Conclusion

In sheet metal processing, reducing the time for tool change not only improves equipment utilization and production efficiency, but also effectively reduces production costs. By adopting a comprehensive approach in equipment optimization, process improvement, and personnel management, enterprises can gain a more advantageous position in fierce market competition. In the future, with the development of intelligent and automated technology, the efficiency of tool change is expected to be further improved, bringing higher benefits and stronger competitiveness to the sheet metal processing industry.

In the sheet metal processing industry, the time for tool change is one of the important factors affecting production efficiency and equipment utilization. With the intensification of market competition, enterprises have higher and higher requirements for production rhythm. How to minimize the time for tool change while ensuring processing quality has become a key link to improve overall production efficiency. This article will discuss how to effectively reduce the time for tool change in sheet metal processing from three aspects: equipment optimization, process improvement, and personnel management.

I. Optimize Equipment Configuration and Tool Change System

Modern sheet metal processing equipment such as presses, laser cutting machines, and bending machines are usually equipped with automatic tool change systems (ATC), but their efficiency still depends on the rationality of tool configuration. Enterprises should reasonably plan the types and quantities of tools in the tool library according to common processing technologies and product types, and avoid repeated or redundant configurations. At the same time, the use of modular tools and standardized interface design can also significantly improve the speed of tool change.

In addition, regular maintenance and maintenance of the tool change system should be carried out to ensure the normal operation of the robotic arm, pneumatic components, and sensors, and to avoid prolonged unplanned downtime due to equipment failure.

II. Optimize Processing Technology and Programming

In the stage of process design, it is advisable to adopt multi-process integrated processing methods as much as possible to reduce unnecessary repeated tool change operations. For example, in the laser cutting process, reasonable layout of cutting paths can achieve the processing of multiple parts in one clamping; in press forming processing, by reasonably arranging the mold sequence, the number of mold changes can be minimized as much as possible.

Using advanced CAM software for intelligent programming can also achieve automatic optimization of tool paths, reduce unnecessary travel, and improve the efficiency of work connection before and after tool change. At the same time, establishing a processing template library for typical parts can help quickly call up mature processes and shorten preparation time.

III. Strengthen Personnel Training and Standardized Management

The skillfulness of personnel operation directly affects the actual time for tool change. Therefore, enterprises should provide systematic skill training for operators, enabling them to be familiar with the equipment operation process, tool change steps, and common problem-solving methods. Implementing standardized operating procedures (SOP) helps to decompose and control the time of the tool change process, which is conducive to reducing delays caused by human factors.

In addition, establishing a performance evaluation mechanism and incorporating the time for tool change into the production assessment system can motivate employees to continuously improve operational efficiency and foster a culture of continuous improvement.

Conclusion

In sheet metal processing, reducing the time for tool change not only improves equipment utilization and production efficiency, but also effectively reduces production costs. By adopting a comprehensive approach in equipment optimization, process improvement, and personnel management, enterprises can gain a more advantageous position in fierce market competition. In the future, with the development of intelligent and automated technology, the efficiency of tool change is expected to be further improved, bringing higher benefits and stronger competitiveness to the sheet metal processing industry.