News

How to reduce the impact of vibration in sheet metal processing

Category:answer Publishing time:2025-12-11 17:01:19 Browse: Times

During the sheet metal processing process, vibration is a common but non-negligible problem. It not only affects the surface quality and processing accuracy of the workpiece but may also shorten the life of the equipment, even posing a threat to the safety of the operators. Therefore, taking effective measures to reduce the impact of vibration in sheet metal processing is an important guarantee for improving production efficiency and product quality.

Firstly, the source of vibration mainly comes from the mechanical structure of the machine tool itself, the cutting force between the tool and the workpiece, the stability of the fixture, and the characteristics of the sheet metal material itself. Especially in high-speed stamping, shearing, and bending processes, the plastic deformation of the metal material will cause periodic or sudden vibration.

To reduce the negative impact of vibration, efforts can be made from the following aspects:

1. Optimize processing parameters

Reasonably setting processing parameters is the first step in vibration reduction. For example, appropriately reducing the stamping speed, adjusting the lower die clearance of the bending machine, and controlling the shearing angle can effectively reduce impact force and vibration frequency. At the same time, avoid processing within the resonance frequency range of the machine tool to prevent vibration amplification.

2. Improve the stability of fixtures and molds

High-rigidity and high-precision fixtures and molds can effectively improve the stability of the workpiece and reduce vibration caused by improper clamping. In addition, regularly checking the wear of molds and replacing aging or damaged mold components in a timely manner is also one of the important means of vibration reduction.

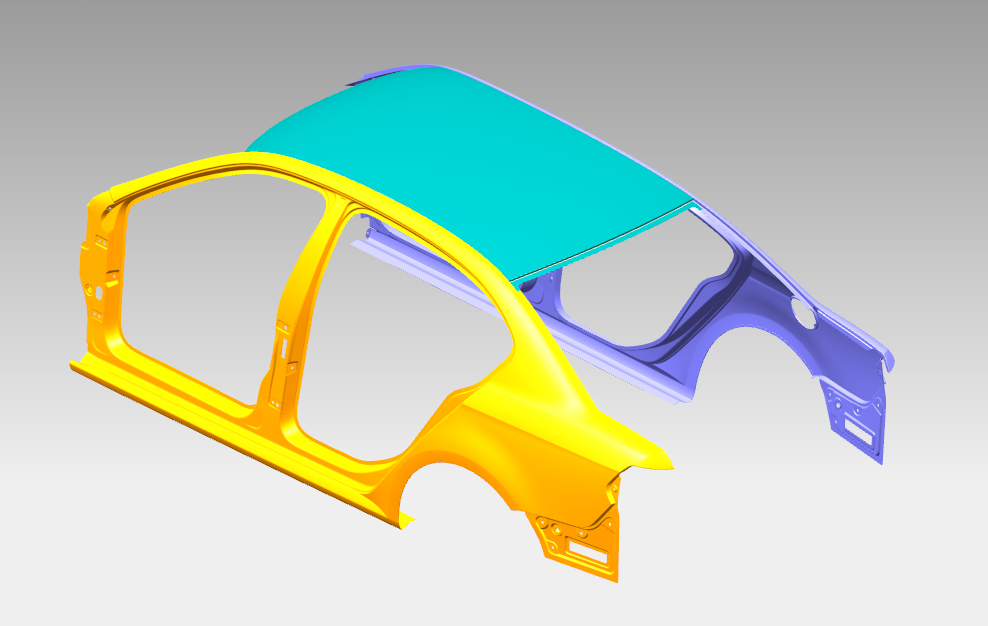

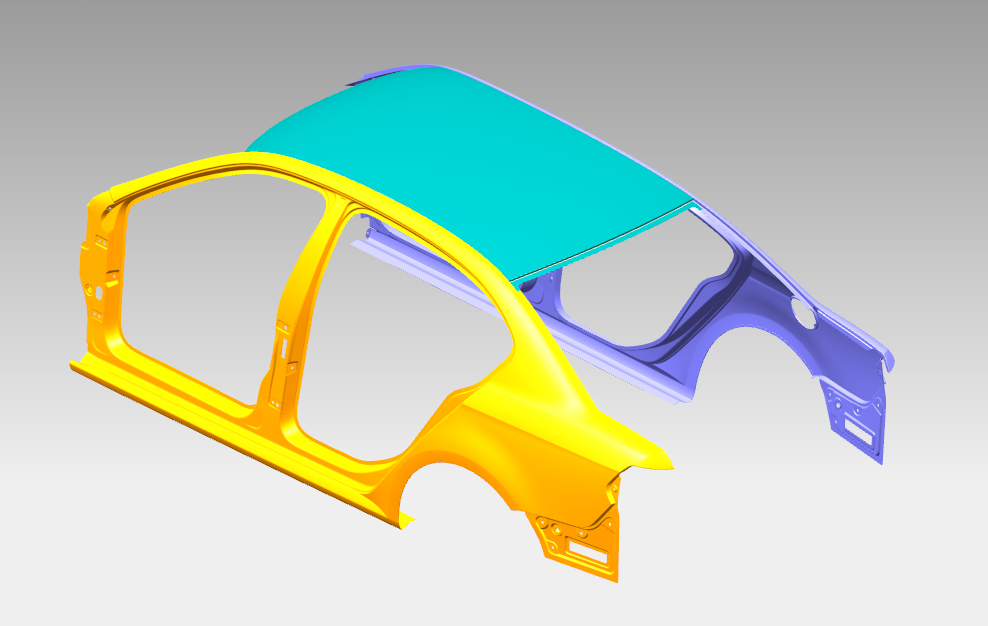

3. Optimize structural design and material selection

When designing sheet metal structures, it should be avoided to have structures that are prone to vibration, such as thin-walled or long cantilever structures. Reasonably arranged reinforcing ribs or flange structures can effectively improve the overall rigidity and thus suppress the occurrence of vibration. At the same time, choosing materials with good vibration absorption properties, such as certain composite materials or porous metal materials, can also play a vibration reduction role.

4. Use vibration reduction equipment and auxiliary devices

More and more vibration reduction technologies are integrated into modern sheet metal processing equipment. For example, adding vibration damping pads to the machine tool base, using active vibration control systems, and installing dynamic vibration absorbers at key locations can significantly reduce the amplitude of vibration. In addition, equipment driven by hydraulic or servo motors has smoother operation characteristics compared to traditional pneumatic or mechanical transmission.

5. Regular maintenance and monitoring

Regular maintenance and calibration of processing equipment ensure the normal operation of key components such as the spindle, guide rail, and screw. This prevents abnormal vibration caused by component wear or loosening. Through the vibration monitoring system, the operation status of the equipment can be monitored in real time, which is helpful for discovering potential problems in advance and avoiding equipment damage and processing accidents.

In summary, while the vibration problem in sheet metal processing is complex, it can be effectively reduced by optimizing the process, selecting the right equipment, designing the structure, and maintaining the equipment on a daily basis. This can enhance processing quality and production efficiency, and ensure production safety. In the trend of intelligent manufacturing in the future, the intelligent vibration reduction system combined with sensor and data analysis technology will also become an important development direction in the field of sheet metal processing.

During the sheet metal processing process, vibration is a common but non-negligible problem. It not only affects the surface quality and processing accuracy of the workpiece but may also shorten the life of the equipment, even posing a threat to the safety of the operators. Therefore, taking effective measures to reduce the impact of vibration in sheet metal processing is an important guarantee for improving production efficiency and product quality.

Firstly, the source of vibration mainly comes from the mechanical structure of the machine tool itself, the cutting force between the tool and the workpiece, the stability of the fixture, and the characteristics of the sheet metal material itself. Especially in high-speed stamping, shearing, and bending processes, the plastic deformation of the metal material will cause periodic or sudden vibration.

To reduce the negative impact of vibration, efforts can be made from the following aspects:

1. Optimize processing parameters

Reasonably setting processing parameters is the first step in vibration reduction. For example, appropriately reducing the stamping speed, adjusting the lower die clearance of the bending machine, and controlling the shearing angle can effectively reduce impact force and vibration frequency. At the same time, avoid processing within the resonance frequency range of the machine tool to prevent vibration amplification.

2. Improve the stability of fixtures and molds

High-rigidity and high-precision fixtures and molds can effectively improve the stability of the workpiece and reduce vibration caused by improper clamping. In addition, regularly checking the wear of molds and replacing aging or damaged mold components in a timely manner is also one of the important means of vibration reduction.

3. Optimize structural design and material selection

When designing sheet metal structures, it should be avoided to have structures that are prone to vibration, such as thin-walled or long cantilever structures. Reasonably arranged reinforcing ribs or flange structures can effectively improve the overall rigidity and thus suppress the occurrence of vibration. At the same time, choosing materials with good vibration absorption properties, such as certain composite materials or porous metal materials, can also play a vibration reduction role.

4. Use vibration reduction equipment and auxiliary devices

More and more vibration reduction technologies are integrated into modern sheet metal processing equipment. For example, adding vibration damping pads to the machine tool base, using active vibration control systems, and installing dynamic vibration absorbers at key locations can significantly reduce the amplitude of vibration. In addition, equipment driven by hydraulic or servo motors has smoother operation characteristics compared to traditional pneumatic or mechanical transmission.

5. Regular maintenance and monitoring

Regular maintenance and calibration of processing equipment ensure the normal operation of key components such as the spindle, guide rail, and screw. This prevents abnormal vibration caused by component wear or loosening. Through the vibration monitoring system, the operation status of the equipment can be monitored in real time, which is helpful for discovering potential problems in advance and avoiding equipment damage and processing accidents.

In summary, while the vibration problem in sheet metal processing is complex, it can be effectively reduced by optimizing the process, selecting the right equipment, designing the structure, and maintaining the equipment on a daily basis. This can enhance processing quality and production efficiency, and ensure production safety. In the trend of intelligent manufacturing in the future, the intelligent vibration reduction system combined with sensor and data analysis technology will also become an important development direction in the field of sheet metal processing.