News

How to prevent the zinc layer from peeling off from galvanized steel plates

Category:answer Publishing time:2025-09-12 07:47:12 Browse: Times

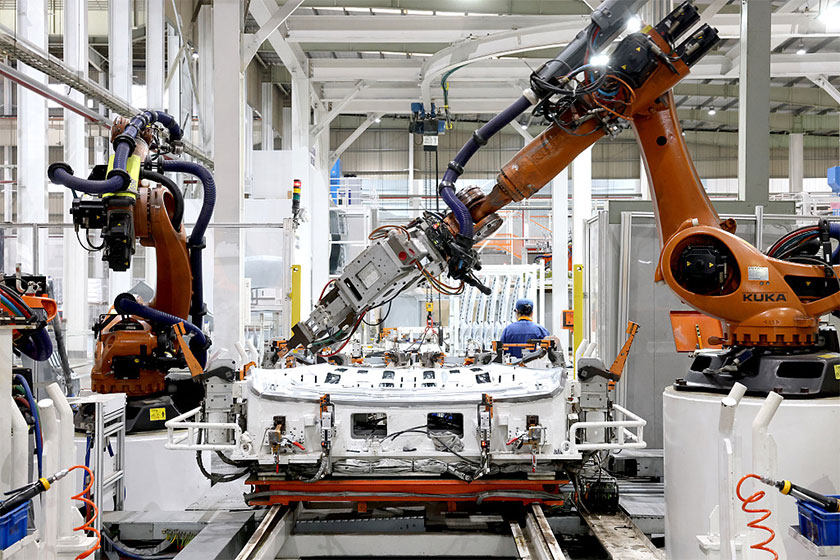

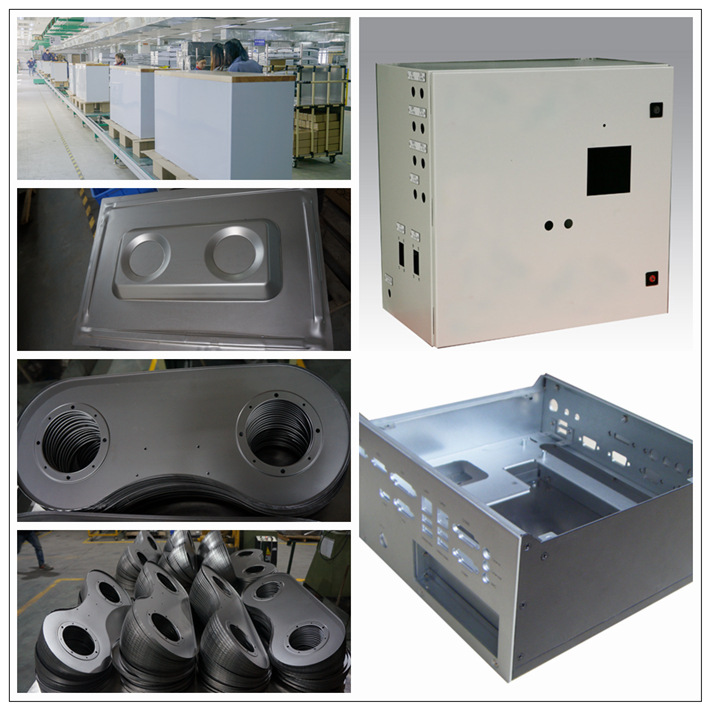

Galvanized steel plate is a metal material coated with a layer of zinc on the surface of the steel plate, widely used in construction, automotive, household appliances, electricity, and other fields. Its main function is to improve the corrosion resistance of the steel plate and extend its service life. However, in actual use, the zinc layer of the galvanized steel plate may peel off, affecting its protective performance. Therefore, taking effective measures to prevent the zinc layer from peeling off is crucial.

Firstly, choosing a high-quality galvanizing process is the foundation for preventing the zinc layer from peeling off. Common galvanizing processes currently include hot-dip galvanizing, electro-galvanizing, and alloy galvanizing, etc. The adhesion and corrosion resistance of the zinc layer vary with different processes. Taking hot-dip galvanizing as an example, if the process parameters are not controlled properly, such as the galvanizing temperature being too high or the cooling speed being too fast, it may lead to a decrease in the bonding force between zinc and the steel plate, thereby causing the zinc layer to peel off. Therefore, strict control of galvanizing temperature, cooling speed, and zinc liquid composition should be ensured during the production process to ensure that the zinc layer is uniform, dense, and firmly bonded to the base material.

Secondly, reasonable surface treatment technology plays a vital role in enhancing the adhesion of the zinc layer. Before galvanizing, the steel plate should be strictly degreased, pickled, and rinsed to remove surface oil, oxides, and other impurities, ensuring a clean surface for the zinc layer to adhere to. In addition, post-treatment measures such as passivation, oiling, or spraying protective coatings can be carried out after galvanizing to further improve the stability of the zinc layer and prevent mechanical damage or chemical corrosion during transportation and use.

Thirdly, avoiding improper operations during processing and use is also an important link in preventing the zinc layer from peeling off. If the galvanized steel plate is not properly handled during processes such as stamping, bending, and welding, the zinc layer may peel off due to mechanical stress. Therefore, processing technologies should be reasonably selected based on the mechanical properties of the galvanized steel plate and the thickness of the zinc layer, avoiding excessive bending or high-speed stamping. At the same time, scratches and collisions should be avoided during handling and storage to prevent physical damage.

Finally, the control of environmental factors should not be ignored. In high humidity, acidic, or salt fog environments, the zinc layer is prone to chemical reactions, accelerating corrosion and peeling off. Therefore, galvanized steel plates should be used in suitable environments as much as possible, and protective measures such as coatings or composite protection should be配合 used when necessary to improve their overall corrosion resistance.

In summary, to effectively avoid the problem of zinc layer peeling off from galvanized steel plates, it is necessary to take comprehensive and scientific measures from multiple aspects such as galvanizing process, surface treatment, processing operations, and usage environment. Only in this way can the excellent corrosion resistance of galvanized steel plates be fully utilized, ensuring their stability and service life in various application scenarios.

Galvanized steel plate is a metal material coated with a layer of zinc on the surface of the steel plate, widely used in construction, automotive, household appliances, electricity, and other fields. Its main function is to improve the corrosion resistance of the steel plate and extend its service life. However, in actual use, the zinc layer of the galvanized steel plate may peel off, affecting its protective performance. Therefore, taking effective measures to prevent the zinc layer from peeling off is crucial.

Firstly, choosing a high-quality galvanizing process is the foundation for preventing the zinc layer from peeling off. Common galvanizing processes currently include hot-dip galvanizing, electro-galvanizing, and alloy galvanizing, etc. The adhesion and corrosion resistance of the zinc layer vary with different processes. Taking hot-dip galvanizing as an example, if the process parameters are not controlled properly, such as the galvanizing temperature being too high or the cooling speed being too fast, it may lead to a decrease in the bonding force between zinc and the steel plate, thereby causing the zinc layer to peel off. Therefore, strict control of galvanizing temperature, cooling speed, and zinc liquid composition should be ensured during the production process to ensure that the zinc layer is uniform, dense, and firmly bonded to the base material.

Secondly, reasonable surface treatment technology plays a vital role in enhancing the adhesion of the zinc layer. Before galvanizing, the steel plate should be strictly degreased, pickled, and rinsed to remove surface oil, oxides, and other impurities, ensuring a clean surface for the zinc layer to adhere to. In addition, post-treatment measures such as passivation, oiling, or spraying protective coatings can be carried out after galvanizing to further improve the stability of the zinc layer and prevent mechanical damage or chemical corrosion during transportation and use.

Thirdly, avoiding improper operations during processing and use is also an important link in preventing the zinc layer from peeling off. If the galvanized steel plate is not properly handled during processes such as stamping, bending, and welding, the zinc layer may peel off due to mechanical stress. Therefore, processing technologies should be reasonably selected based on the mechanical properties of the galvanized steel plate and the thickness of the zinc layer, avoiding excessive bending or high-speed stamping. At the same time, scratches and collisions should be avoided during handling and storage to prevent physical damage.

Finally, the control of environmental factors should not be ignored. In high humidity, acidic, or salt fog environments, the zinc layer is prone to chemical reactions, accelerating corrosion and peeling off. Therefore, galvanized steel plates should be used in suitable environments as much as possible, and protective measures such as coatings or composite protection should be配合 used when necessary to improve their overall corrosion resistance.

In summary, to effectively avoid the problem of zinc layer peeling off from galvanized steel plates, it is necessary to take comprehensive and scientific measures from multiple aspects such as galvanizing process, surface treatment, processing operations, and usage environment. Only in this way can the excellent corrosion resistance of galvanized steel plates be fully utilized, ensuring their stability and service life in various application scenarios.