News

How to optimize the path in sheet incremental forming

Category:answer Publishing time:2025-11-09 19:13:05 Browse: Times

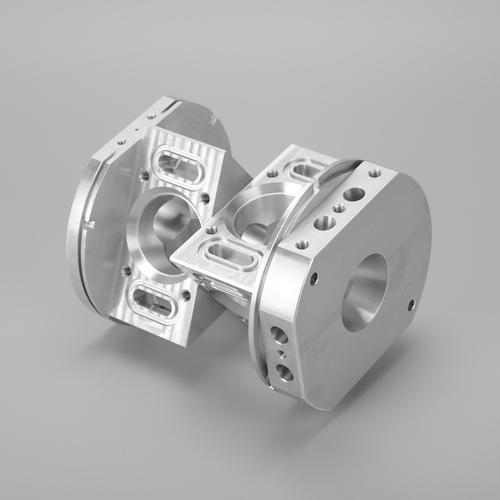

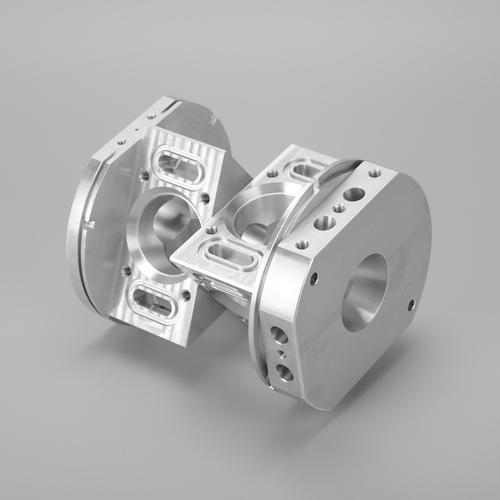

With the continuous growth of modern manufacturing industry's demand for complex part manufacturing, incremental sheet forming (Incremental Sheet Forming, ISF) as a flexible and efficient non-mold forming technology has gradually received extensive attention. This technology gradually forms the required three-dimensional parts by means of numerical control machine tools or robotic control of the tool head to locally deform the sheet material, and finally forms the required three-dimensional parts, which has the advantages of low cost, short cycle, and strong adaptability. However, in practical applications, the design of the forming path has a direct impact on the forming quality, efficiency, and material properties. Therefore, how to optimize the forming path has become a key issue to improve the process level of sheet incremental forming.

One, Importance of Path Optimization

The forming path determines the movement trajectory of the tool head on the sheet, directly affecting the material flow, thickness distribution, and forming limit. Unreasonable paths can lead to local thinning, wrinkling, and springback, affecting the forming accuracy and mechanical properties of the part. In addition, path design also affects forming time and energy consumption, and optimizing the path helps to improve production efficiency and reduce manufacturing costs.

Two, Main Methods of Path Optimization

1. Layered Slicing Method

Layered slicing method is the most common path generation method, which is based on the principle of slicing the three-dimensional model along the height direction, with each layer corresponding to a forming path. This method is simple to implement, but it is easy to cause stress concentration in areas with corners or large curvature changes.

2. Adaptive Path Planning

Adaptive path planning dynamically adjusts the step size and path direction according to the geometric characteristics of the part, especially suitable for areas with large curvature changes. This method can effectively reduce material thinning and improve the uniformity of forming.

3. Path Optimization Based on Finite Element Analysis

Using finite element simulation technology, predict the stress and strain distribution under various paths during the forming process, and optimize the path based on this to achieve the minimum thickness thinning and the maximum forming limit. This method has a large amount of calculation, but can significantly improve the forming quality.

4. Intelligent Algorithm Optimization Method

In recent years, intelligent optimization algorithms such as genetic algorithms, ant colony algorithms, and particle swarm optimization algorithms have been introduced into path optimization research. These algorithms can efficiently search for the optimal path scheme and are particularly suitable for path planning of complex geometric shapes.

Three, Future Development Direction

In the future, path optimization will pay more attention to multi-objective collaborative optimization, such as taking into account forming efficiency and energy consumption while improving forming quality. At the same time, with the development of artificial intelligence and big data technology, path prediction and optimization methods based on machine learning are expected to become research hotspots. Integrating online monitoring and feedback control technology, realizing an integrated adaptive forming system of 'perception-decision-execution', will be an important direction for the intelligent development of sheet metal gradual forming.

Four, Conclusion

Sheet metal gradual forming, as an important part of advanced manufacturing technology, is constantly promoting the efficient manufacturing of personalized and small batch products. The optimization design of the forming path, as one of the core factors affecting the forming effect, is worthy of in-depth study and continuous exploration. Through multidisciplinary integration and technological innovation, path optimization will lay a solid foundation for the gradual forming of sheet metal to achieve higher precision, higher quality, and higher efficiency.

With the continuous growth of modern manufacturing industry's demand for complex part manufacturing, incremental sheet forming (Incremental Sheet Forming, ISF) as a flexible and efficient non-mold forming technology has gradually received extensive attention. This technology gradually forms the required three-dimensional parts by means of numerical control machine tools or robotic control of the tool head to locally deform the sheet material, and finally forms the required three-dimensional parts, which has the advantages of low cost, short cycle, and strong adaptability. However, in practical applications, the design of the forming path has a direct impact on the forming quality, efficiency, and material properties. Therefore, how to optimize the forming path has become a key issue to improve the process level of sheet incremental forming.

One, Importance of Path Optimization

The forming path determines the movement trajectory of the tool head on the sheet, directly affecting the material flow, thickness distribution, and forming limit. Unreasonable paths can lead to local thinning, wrinkling, and springback, affecting the forming accuracy and mechanical properties of the part. In addition, path design also affects forming time and energy consumption, and optimizing the path helps to improve production efficiency and reduce manufacturing costs.

Two, Main Methods of Path Optimization

1. Layered Slicing Method

Layered slicing method is the most common path generation method, which is based on the principle of slicing the three-dimensional model along the height direction, with each layer corresponding to a forming path. This method is simple to implement, but it is easy to cause stress concentration in areas with corners or large curvature changes.

2. Adaptive Path Planning

Adaptive path planning dynamically adjusts the step size and path direction according to the geometric characteristics of the part, especially suitable for areas with large curvature changes. This method can effectively reduce material thinning and improve the uniformity of forming.

3. Path Optimization Based on Finite Element Analysis

Using finite element simulation technology, predict the stress and strain distribution under various paths during the forming process, and optimize the path based on this to achieve the minimum thickness thinning and the maximum forming limit. This method has a large amount of calculation, but can significantly improve the forming quality.

4. Intelligent Algorithm Optimization Method

In recent years, intelligent optimization algorithms such as genetic algorithms, ant colony algorithms, and particle swarm optimization algorithms have been introduced into path optimization research. These algorithms can efficiently search for the optimal path scheme and are particularly suitable for path planning of complex geometric shapes.

Three, Future Development Direction

In the future, path optimization will pay more attention to multi-objective collaborative optimization, such as taking into account forming efficiency and energy consumption while improving forming quality. At the same time, with the development of artificial intelligence and big data technology, path prediction and optimization methods based on machine learning are expected to become research hotspots. Integrating online monitoring and feedback control technology, realizing an integrated adaptive forming system of 'perception-decision-execution', will be an important direction for the intelligent development of sheet metal gradual forming.

Four, Conclusion

Sheet metal gradual forming, as an important part of advanced manufacturing technology, is constantly promoting the efficient manufacturing of personalized and small batch products. The optimization design of the forming path, as one of the core factors affecting the forming effect, is worthy of in-depth study and continuous exploration. Through multidisciplinary integration and technological innovation, path optimization will lay a solid foundation for the gradual forming of sheet metal to achieve higher precision, higher quality, and higher efficiency.