News

How to manage production plans in sheet metal manufacturing

Category:answer Publishing time:2025-10-06 09:22:34 Browse: Times

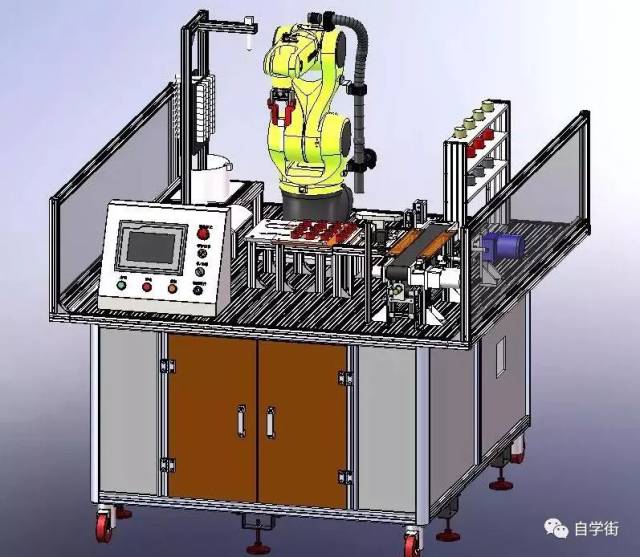

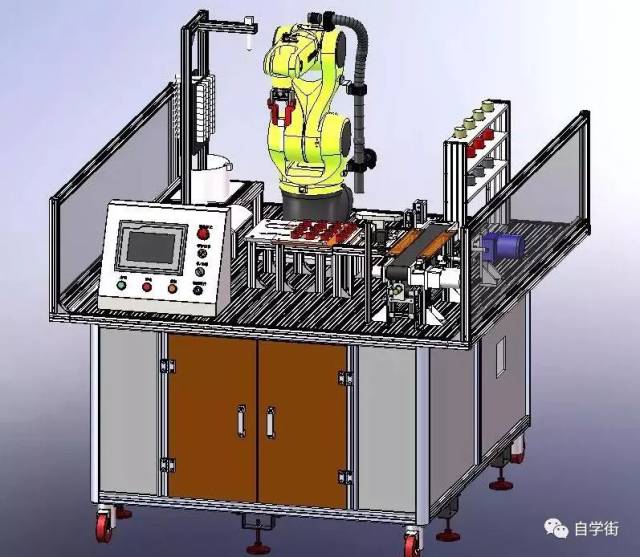

In modern manufacturing, sheet metal processing as an important process form is widely used in many fields such as automobiles, electronics, aerospace, and construction. Due to the complexity of sheet metal manufacturing processes, diversity of materials, and high process requirements, how to scientifically manage production plans has become a key factor for enterprises to improve efficiency, reduce costs, and ensure delivery.

I. Clarifying the Goals of Production Planning

Good production plan management first requires clear goals, including: ensuring timely delivery of orders, reasonable allocation of production resources, reducing equipment idleness and human waste, controlling inventory levels, and improving overall production efficiency. In sheet metal manufacturing, due to the diversity of product types, long processing processes, enterprises must formulate detailed plans according to order priority, delivery time, and process complexity.

II. Rational Production Scheduling and Resource Optimization

Sheet metal manufacturing involves multiple stages such as cutting, stamping, bending, welding, and painting. Each stage relies on specific equipment and process personnel. Therefore, when formulating production plans, factors such as equipment capacity, worker skills, and material supply should be comprehensively considered to rationally schedule production and avoid bottlenecks in the process that lead to the halt of the entire production line.

Using advanced production planning software or ERP systems can achieve real-time monitoring and scheduling of orders, inventory, and processes, improving the accuracy and flexibility of the plan. For example, by setting priority rules in the system, automatically adjusting the order sequence helps to respond quickly in emergencies (such as equipment failure, order changes).

III. Strengthening Material and Process Management

The smooth implementation of the production plan depends on the timeliness of material supply. Sheet metal manufacturing usually involves various types of metal materials, such as stainless steel, cold-rolled steel, galvanized steel, etc. When formulating plans, enterprises need to closely collaborate with procurement and warehousing departments to ensure that raw materials are on time.

At the same time, different products require different process paths, and it is necessary to do a good job in process review and standardized process design in advance to reduce rework and delays caused by process changes. Establishing Standard Operating Procedures (SOP) and training operators is an important means to improve the execution of production plans.

IV. Strengthening Communication and Feedback Mechanisms

The production plan is not a static document, but a dynamic process. In actual implementation, workshop managers should communicate regularly with the planning department, promptly feedback on progress, issues, and adjustment requirements. Through daily morning meetings, bulletin board management, or digital bulletin board systems, information transparency can be improved, ensuring that all departments work in coordination.

V. Continuous Improvement and Data Analysis

By analyzing key indicators such as production plan completion rate, equipment utilization rate, and on-time delivery rate, the production management system is continuously optimized. Data-driven decision-making helps to identify potential problems and make targeted improvements, thereby continuously enhancing the planning management level and overall competitiveness of sheet metal manufacturing enterprises.

In summary, the production plan for sheet metal manufacturing under scientific management is not only a means to improve efficiency, but also the core of enterprises achieving lean production and enhancing market responsiveness. Through goal-oriented, resource integration, process optimization, and data-driven approaches, enterprises can steadily advance in the fierce market competition.

In modern manufacturing, sheet metal processing as an important process form is widely used in many fields such as automobiles, electronics, aerospace, and construction. Due to the complexity of sheet metal manufacturing processes, diversity of materials, and high process requirements, how to scientifically manage production plans has become a key factor for enterprises to improve efficiency, reduce costs, and ensure delivery.

I. Clarifying the Goals of Production Planning

Good production plan management first requires clear goals, including: ensuring timely delivery of orders, reasonable allocation of production resources, reducing equipment idleness and human waste, controlling inventory levels, and improving overall production efficiency. In sheet metal manufacturing, due to the diversity of product types, long processing processes, enterprises must formulate detailed plans according to order priority, delivery time, and process complexity.

II. Rational Production Scheduling and Resource Optimization

Sheet metal manufacturing involves multiple stages such as cutting, stamping, bending, welding, and painting. Each stage relies on specific equipment and process personnel. Therefore, when formulating production plans, factors such as equipment capacity, worker skills, and material supply should be comprehensively considered to rationally schedule production and avoid bottlenecks in the process that lead to the halt of the entire production line.

Using advanced production planning software or ERP systems can achieve real-time monitoring and scheduling of orders, inventory, and processes, improving the accuracy and flexibility of the plan. For example, by setting priority rules in the system, automatically adjusting the order sequence helps to respond quickly in emergencies (such as equipment failure, order changes).

III. Strengthening Material and Process Management

The smooth implementation of the production plan depends on the timeliness of material supply. Sheet metal manufacturing usually involves various types of metal materials, such as stainless steel, cold-rolled steel, galvanized steel, etc. When formulating plans, enterprises need to closely collaborate with procurement and warehousing departments to ensure that raw materials are on time.

At the same time, different products require different process paths, and it is necessary to do a good job in process review and standardized process design in advance to reduce rework and delays caused by process changes. Establishing Standard Operating Procedures (SOP) and training operators is an important means to improve the execution of production plans.

IV. Strengthening Communication and Feedback Mechanisms

The production plan is not a static document, but a dynamic process. In actual implementation, workshop managers should communicate regularly with the planning department, promptly feedback on progress, issues, and adjustment requirements. Through daily morning meetings, bulletin board management, or digital bulletin board systems, information transparency can be improved, ensuring that all departments work in coordination.

V. Continuous Improvement and Data Analysis

By analyzing key indicators such as production plan completion rate, equipment utilization rate, and on-time delivery rate, the production management system is continuously optimized. Data-driven decision-making helps to identify potential problems and make targeted improvements, thereby continuously enhancing the planning management level and overall competitiveness of sheet metal manufacturing enterprises.

In summary, the production plan for sheet metal manufacturing under scientific management is not only a means to improve efficiency, but also the core of enterprises achieving lean production and enhancing market responsiveness. Through goal-oriented, resource integration, process optimization, and data-driven approaches, enterprises can steadily advance in the fierce market competition.