News

How to improve the process stability of sheet metal processing

Category:answer Publishing time:2025-10-22 18:04:33 Browse: Times

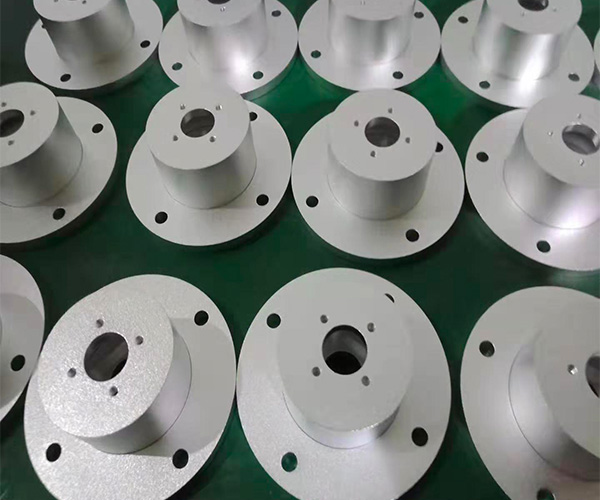

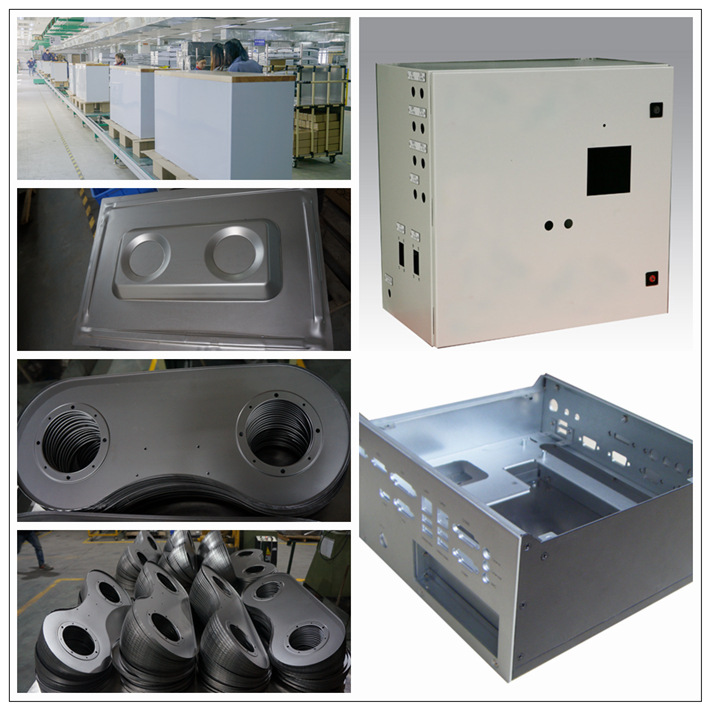

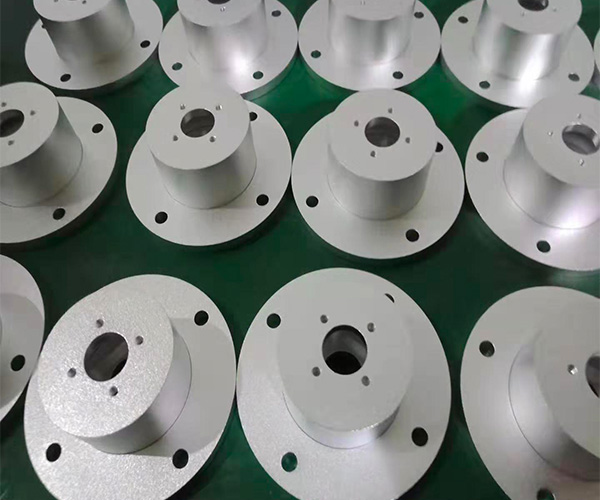

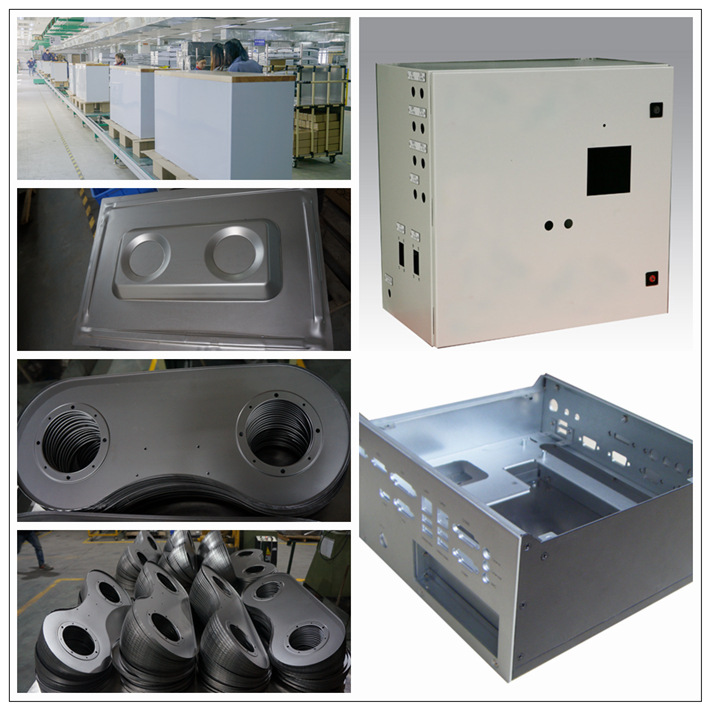

Firstly, optimizing process parameters is the key to improving stability. Sheet metal processing includes shearing, stamping, bending, welding, and other processes, and the parameter settings of each link directly affect the final product quality. Enterprises should reasonably set parameters such as pressure, speed, temperature, and die clearance according to material characteristics, equipment performance, and product requirements, and continuously optimize them through experiments and data analysis, establish standardized operation instructions, and ensure that operators can strictly follow the specifications.

Secondly, strengthening equipment maintenance and management is the foundation for improving stability. High-precision processing equipment is the premise of ensuring the consistency of sheet metal processing. Enterprises should calibrate and maintain key equipment such as press brakes, laser cutting machines, and CNC bending machines regularly to ensure their optimal operating status. At the same time, introduce automated detection systems such as online size detection and visual recognition systems to achieve real-time monitoring of the processing process, and timely discover and correct deviations.

Thirdly, strict control of raw material quality is essential. There may be differences in thickness, hardness, surface treatment, and other aspects among metal sheets from different batches and manufacturers, which are easy to cause problems such as rebound and cracking during the processing process. Therefore, it is necessary to establish a complete raw material inspection mechanism, select suppliers with stable performance and reliable quality, and conduct sampling inspections before entering the warehouse.

In addition, it is also important not to ignore the improvement of the professional skills of the operators. Even if the equipment and process are advanced, if the operators lack experience or improper operation, it will affect the processing quality. Enterprises should organize technical training regularly to enhance the quality awareness and standardized operation ability of employees, and at the same time establish incentive mechanisms to encourage employees to participate in process improvement.

Finally, with the help of information and intelligent means, promote the transformation of sheet metal processing to intelligent manufacturing. For example, introducing MES system to achieve real-time collection and analysis of production process data, using big data to predict possible process anomalies, and thus intervene in advance to improve the overall process stability.

In summary, to improve the process stability of sheet metal processing, it is necessary to start from multiple aspects such as process optimization, equipment management, raw material control, employee training, and intelligent manufacturing, forming a systematic quality assurance system. Only in this way can we continuously enhance product competitiveness in the fierce market competition and achieve sustainable development.

Firstly, optimizing process parameters is the key to improving stability. Sheet metal processing includes shearing, stamping, bending, welding, and other processes, and the parameter settings of each link directly affect the final product quality. Enterprises should reasonably set parameters such as pressure, speed, temperature, and die clearance according to material characteristics, equipment performance, and product requirements, and continuously optimize them through experiments and data analysis, establish standardized operation instructions, and ensure that operators can strictly follow the specifications.

Secondly, strengthening equipment maintenance and management is the foundation for improving stability. High-precision processing equipment is the premise of ensuring the consistency of sheet metal processing. Enterprises should calibrate and maintain key equipment such as press brakes, laser cutting machines, and CNC bending machines regularly to ensure their optimal operating status. At the same time, introduce automated detection systems such as online size detection and visual recognition systems to achieve real-time monitoring of the processing process, and timely discover and correct deviations.

Thirdly, strict control of raw material quality is essential. There may be differences in thickness, hardness, surface treatment, and other aspects among metal sheets from different batches and manufacturers, which are easy to cause problems such as rebound and cracking during the processing process. Therefore, it is necessary to establish a complete raw material inspection mechanism, select suppliers with stable performance and reliable quality, and conduct sampling inspections before entering the warehouse.

In addition, it is also important not to ignore the improvement of the professional skills of the operators. Even if the equipment and process are advanced, if the operators lack experience or improper operation, it will affect the processing quality. Enterprises should organize technical training regularly to enhance the quality awareness and standardized operation ability of employees, and at the same time establish incentive mechanisms to encourage employees to participate in process improvement.

Finally, with the help of information and intelligent means, promote the transformation of sheet metal processing to intelligent manufacturing. For example, introducing MES system to achieve real-time collection and analysis of production process data, using big data to predict possible process anomalies, and thus intervene in advance to improve the overall process stability.

In summary, to improve the process stability of sheet metal processing, it is necessary to start from multiple aspects such as process optimization, equipment management, raw material control, employee training, and intelligent manufacturing, forming a systematic quality assurance system. Only in this way can we continuously enhance product competitiveness in the fierce market competition and achieve sustainable development.