News

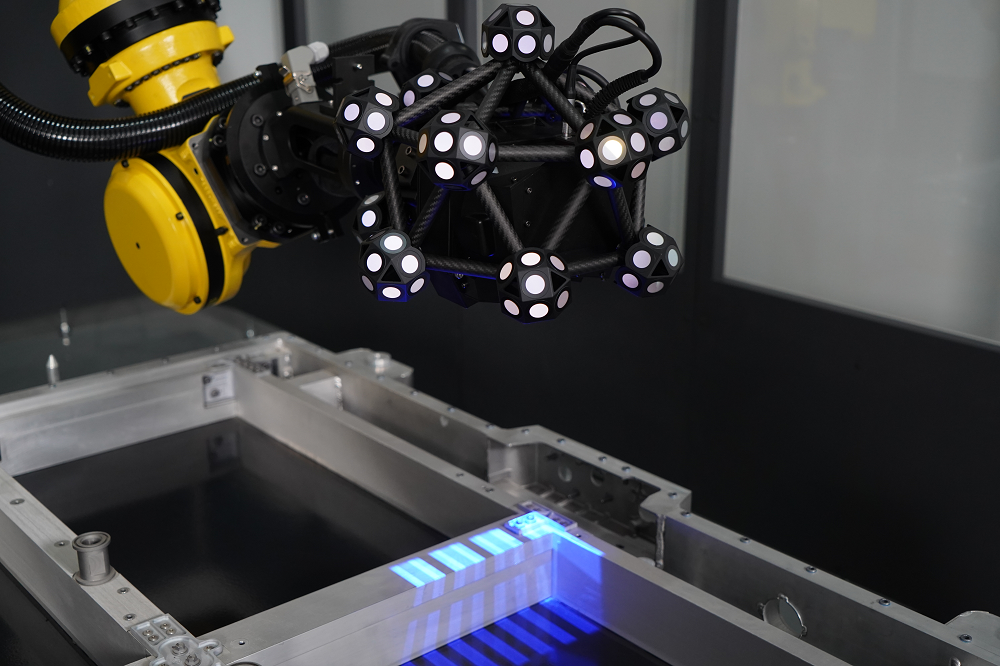

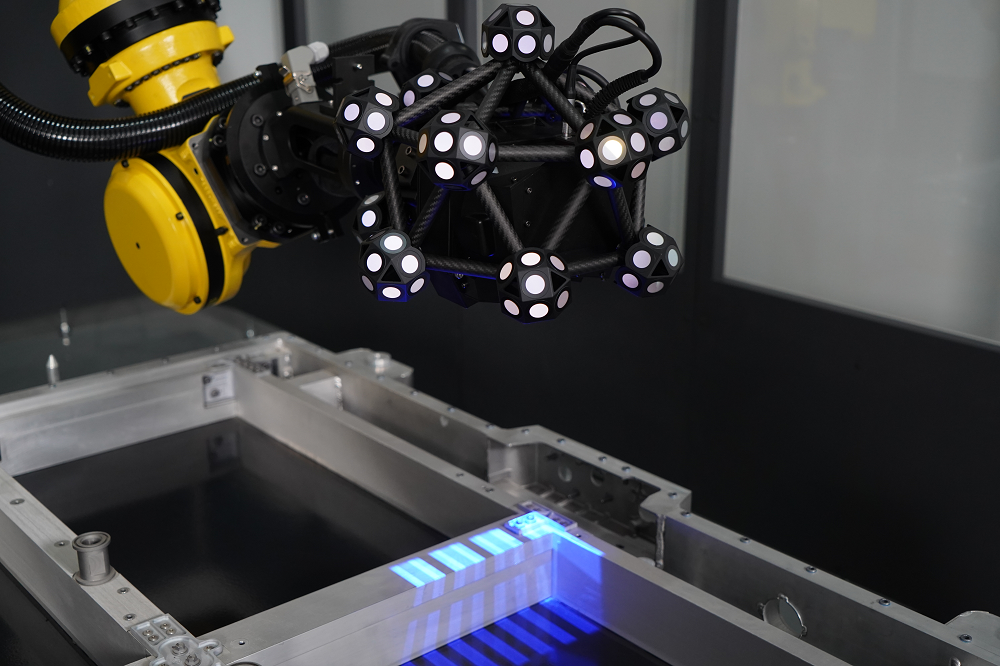

How to improve the precision of sheet metal electromagnetic forming

Category:answer Publishing time:2025-12-06 11:43:32 Browse: Times

Firstly, the precision of electromagnetic forming is directly affected by the distribution of the electromagnetic field. To improve the forming precision, it is necessary to optimize the coil structure and arrangement. By using finite element simulation technology, the distribution of the electromagnetic field and the induced eddy currents can be accurately simulated, thus designing more reasonable coil shapes and positions, making the distribution of electromagnetic force more uniform, reducing local stress concentration, and thereby improving the consistency and dimensional accuracy of the workpiece forming.

Secondly, the stability of material properties has an important impact on forming precision. The responses of materials from different batches or directions may vary under the action of the electromagnetic field. Therefore, strict screening and pretreatment of materials should be carried out before forming to ensure their consistent mechanical properties and electrical conductivity. At the same time, establishing a material database and optimizing the actual process parameters will help improve the controllability of the forming process.

Moreover, the precision and response speed of the control system are also key factors affecting the quality of electromagnetic forming. The use of high-precision power supply control systems and real-time feedback regulation mechanisms can effectively control the discharge energy and pulse time, thus achieving precise control over the size and duration of the electromagnetic force. In addition, the introduction of intelligent control systems, combined with artificial intelligence algorithms to optimize control strategies, also helps to enhance the stability and repeatability of the forming process.

Finally, reasonable process parameter matching is the foundation for improving forming precision. The selection of parameters such as discharge voltage, capacitance capacity, coil and workpiece spacing, and forming gap all need to be continuously optimized through experiments and simulations. Especially in the multi-pass forming process, the forming energy of each pass should be adjusted according to the material deformation characteristics to avoid excessive deformation causing springback or cracking, thereby improving the overall forming precision.

In summary, to improve the precision of electromagnetic sheet metal forming, it is necessary to start from multiple aspects such as electromagnetic field design, material property management, control system optimization, and process parameter regulation. With the development of simulation technology, intelligent control, and advanced manufacturing technology, electromagnetic forming will achieve higher precision applications in the future, providing more excellent solutions for high-end manufacturing fields such as aerospace, automotive lightweighting, and precision electronics.

Firstly, the precision of electromagnetic forming is directly affected by the distribution of the electromagnetic field. To improve the forming precision, it is necessary to optimize the coil structure and arrangement. By using finite element simulation technology, the distribution of the electromagnetic field and the induced eddy currents can be accurately simulated, thus designing more reasonable coil shapes and positions, making the distribution of electromagnetic force more uniform, reducing local stress concentration, and thereby improving the consistency and dimensional accuracy of the workpiece forming.

Secondly, the stability of material properties has an important impact on forming precision. The responses of materials from different batches or directions may vary under the action of the electromagnetic field. Therefore, strict screening and pretreatment of materials should be carried out before forming to ensure their consistent mechanical properties and electrical conductivity. At the same time, establishing a material database and optimizing the actual process parameters will help improve the controllability of the forming process.

Moreover, the precision and response speed of the control system are also key factors affecting the quality of electromagnetic forming. The use of high-precision power supply control systems and real-time feedback regulation mechanisms can effectively control the discharge energy and pulse time, thus achieving precise control over the size and duration of the electromagnetic force. In addition, the introduction of intelligent control systems, combined with artificial intelligence algorithms to optimize control strategies, also helps to enhance the stability and repeatability of the forming process.

Finally, reasonable process parameter matching is the foundation for improving forming precision. The selection of parameters such as discharge voltage, capacitance capacity, coil and workpiece spacing, and forming gap all need to be continuously optimized through experiments and simulations. Especially in the multi-pass forming process, the forming energy of each pass should be adjusted according to the material deformation characteristics to avoid excessive deformation causing springback or cracking, thereby improving the overall forming precision.

In summary, to improve the precision of electromagnetic sheet metal forming, it is necessary to start from multiple aspects such as electromagnetic field design, material property management, control system optimization, and process parameter regulation. With the development of simulation technology, intelligent control, and advanced manufacturing technology, electromagnetic forming will achieve higher precision applications in the future, providing more excellent solutions for high-end manufacturing fields such as aerospace, automotive lightweighting, and precision electronics.