News

How to improve the interchangeability of hardware accessories

Category:answer Publishing time:2025-11-29 18:04:31 Browse: Times

Firstly, the key to improving the interchangeability of hardware accessories lies in standardized production. Standardization is the foundation for interchangeability, and only by unifying standards in terms of size, shape, tolerance, and material, can accessories produced by different manufacturers achieve seamless connection. Enterprises should actively adopt internationally recognized standard systems such as ISO, GB (National Standard), or industry standards, and strictly implement them in design and production processes. Through standardized management, not only can product versatility be improved, but production costs can also be reduced, and market competitiveness can be enhanced.

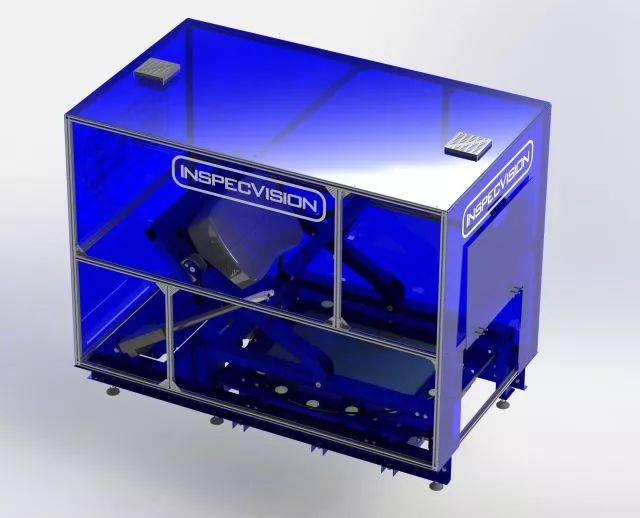

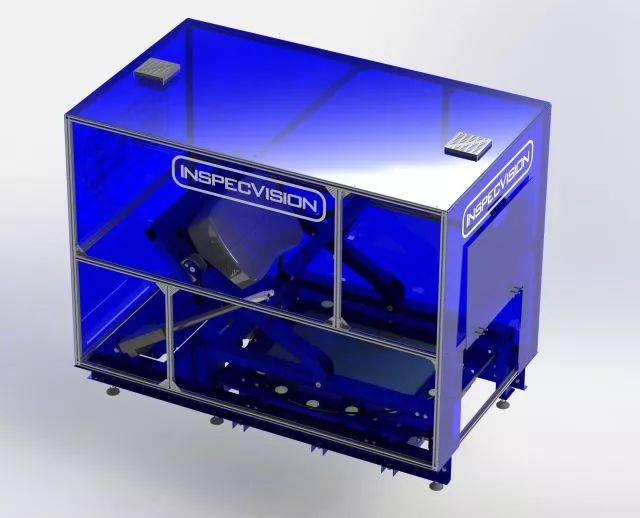

Secondly, the use of high-precision processing equipment and advanced technology in the manufacturing process is also an important means to improve interchangeability. For example, using numerical control machine tools (CNC) for precision processing can effectively control the dimensional error of parts; adopting automated inspection equipment such as coordinate measuring machines, optical projection instruments, etc., for full or random inspection of products ensures that each component meets the specified tolerance range. In addition, surface treatment technologies such as electroplating, oxidation, and spraying should also unify the process flow to ensure consistency in appearance quality and corrosion resistance.

Thirdly, strengthening the construction of the quality management system is also an important guarantee for improving interchangeability. Enterprises should establish a sound quality control system, implementing full-process quality monitoring from raw material procurement, production process control, to finished product delivery. Implementing quality management system certifications such as ISO 9001 helps to standardize internal operational processes and ensure product consistency and stability.

In addition, the application of information systems is also playing an increasingly important role in improving interchangeability. Through systems such as ERP and MES, enterprises can achieve centralized management of product data, ensuring consistency of data in design, production, and inspection processes. At the same time, establishing a product database and providing detailed specifications and parameters also helps customers quickly find suitable alternatives during the selection and use process.

In summary, improving the interchangeability of hardware accessories not only helps to enhance production efficiency and product quality, but also reduces maintenance costs and strengthens market responsiveness. While pursuing technological innovation and quality improvement, enterprises should integrate standardization, precision manufacturing, quality management, and information construction organically, and comprehensively promote the improvement of the interchangeability of hardware accessories to adapt to increasingly fierce market competition and diverse customer needs.

Firstly, the key to improving the interchangeability of hardware accessories lies in standardized production. Standardization is the foundation for interchangeability, and only by unifying standards in terms of size, shape, tolerance, and material, can accessories produced by different manufacturers achieve seamless connection. Enterprises should actively adopt internationally recognized standard systems such as ISO, GB (National Standard), or industry standards, and strictly implement them in design and production processes. Through standardized management, not only can product versatility be improved, but production costs can also be reduced, and market competitiveness can be enhanced.

Secondly, the use of high-precision processing equipment and advanced technology in the manufacturing process is also an important means to improve interchangeability. For example, using numerical control machine tools (CNC) for precision processing can effectively control the dimensional error of parts; adopting automated inspection equipment such as coordinate measuring machines, optical projection instruments, etc., for full or random inspection of products ensures that each component meets the specified tolerance range. In addition, surface treatment technologies such as electroplating, oxidation, and spraying should also unify the process flow to ensure consistency in appearance quality and corrosion resistance.

Thirdly, strengthening the construction of the quality management system is also an important guarantee for improving interchangeability. Enterprises should establish a sound quality control system, implementing full-process quality monitoring from raw material procurement, production process control, to finished product delivery. Implementing quality management system certifications such as ISO 9001 helps to standardize internal operational processes and ensure product consistency and stability.

In addition, the application of information systems is also playing an increasingly important role in improving interchangeability. Through systems such as ERP and MES, enterprises can achieve centralized management of product data, ensuring consistency of data in design, production, and inspection processes. At the same time, establishing a product database and providing detailed specifications and parameters also helps customers quickly find suitable alternatives during the selection and use process.

In summary, improving the interchangeability of hardware accessories not only helps to enhance production efficiency and product quality, but also reduces maintenance costs and strengthens market responsiveness. While pursuing technological innovation and quality improvement, enterprises should integrate standardization, precision manufacturing, quality management, and information construction organically, and comprehensively promote the improvement of the interchangeability of hardware accessories to adapt to increasingly fierce market competition and diverse customer needs.