News

How to improve the corrosion resistance of stainless steel sheet metal

Category:answer Publishing time:2025-09-17 22:03:28 Browse: Times

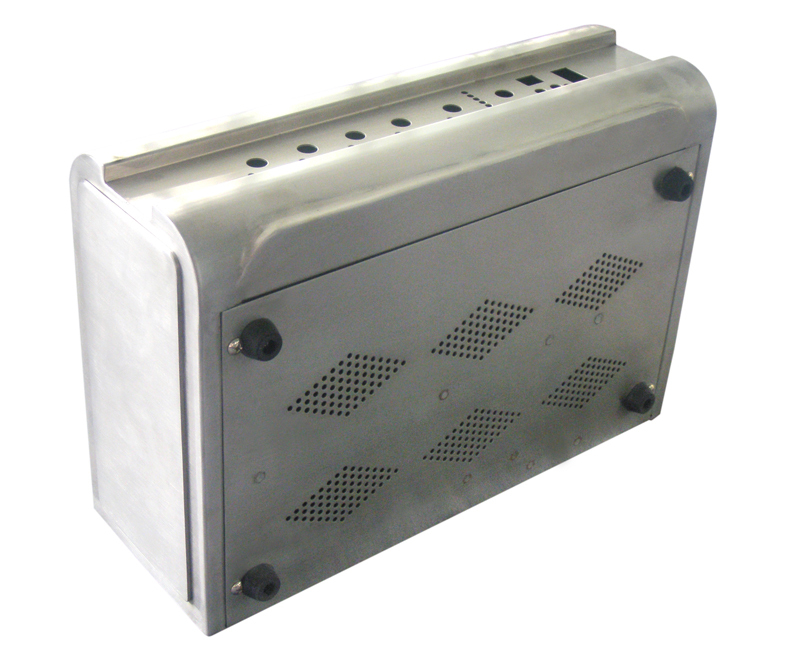

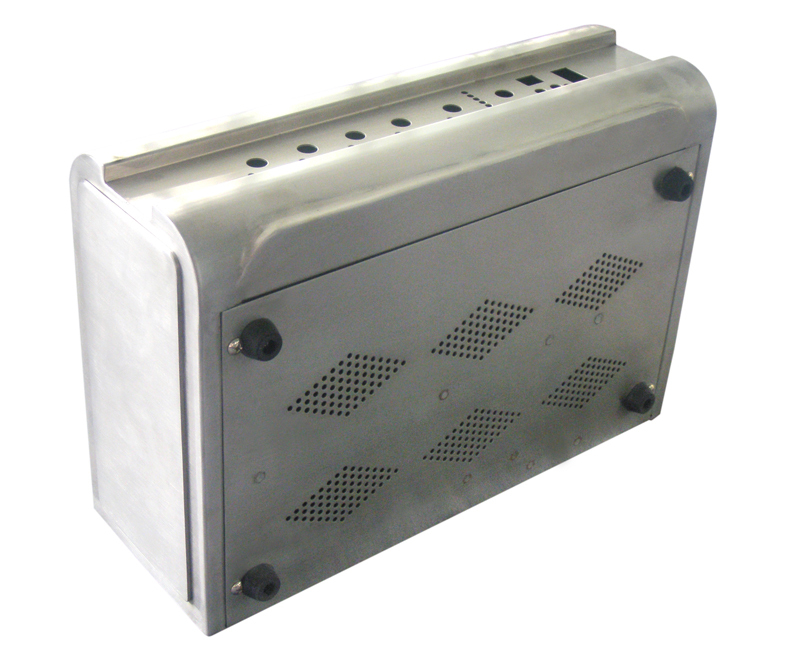

Stainless steel sheet metal is widely used in fields such as construction, chemical industry, food processing, medical devices, etc., due to its good mechanical properties, aesthetic appearance, and certain corrosion resistance. However, in some harsh environments (such as high salt content, high humidity, or acidic and alkaline environments), ordinary stainless steel sheet metal may still exhibit corrosion phenomena. Therefore, further improving the corrosion resistance of stainless steel sheet metal is particularly important. This article will discuss effective methods for improving the corrosion resistance of stainless steel sheet metal from aspects such as material selection, surface treatment processes, and post-maintenance.

Firstly, choosing the appropriate stainless steel material is the foundation for improving corrosion resistance. Different types of stainless steel have varying compositions and corrosion resistance. For example, 304 stainless steel is suitable for general environments, while 316 stainless steel, due to the addition of molybdenum, has stronger resistance to chloride ion corrosion and is more suitable for marine environments or chemical industries. In addition, duplex stainless steel and super austenitic stainless steel also show excellent performance in specific corrosion environments.

Secondly, surface treatment processes are crucial for enhancing corrosion resistance. Common surface treatment methods include passivation, electrolytic polishing, sandblasting, and coating treatment. Among them, passivation treatment forms a dense oxide chrome protective film on the surface of stainless steel through chemical means, which can effectively prevent the contact of metal with corrosive media; electrolytic polishing can not only improve the surface smoothness but also remove surface impurities, enhancing the material's corrosion resistance; for some special application environments, spraying corrosion-resistant coatings or electroplating with nickel, chrome, and other methods can further enhance the protective effect.

Thirdly, reasonable structural design and manufacturing processes can also indirectly enhance the corrosion resistance of stainless steel sheet metal. For example, avoiding the design of dead corners or gap structures can reduce the accumulation of corrosive media; when using welding processes, it should be controlled to prevent intergranular corrosion; surface scratches or mechanical damage should be avoided during sheet metal processing to prevent the destruction of the surface protective layer.

Finally, daily maintenance and cleaning are also important links in maintaining the corrosion resistance of stainless steel sheet metal. Regularly cleaning surface dirt, especially removing corrosive substances such as chlorides and sulfides, can significantly extend the service life of the material. Using neutral or weakly acidic cleaners, and avoiding cleaners containing chloride ions, helps maintain the surface condition of stainless steel.

In summary, to improve the corrosion resistance of stainless steel sheet metal, it is necessary to consider multiple aspects such as material selection, surface treatment, manufacturing process, and daily maintenance. Through scientific design and reasonable processing methods, stainless steel sheet metal can maintain good stability and service life in complex environments, meeting the needs of various industries for high-performance materials.

Stainless steel sheet metal is widely used in fields such as construction, chemical industry, food processing, medical devices, etc., due to its good mechanical properties, aesthetic appearance, and certain corrosion resistance. However, in some harsh environments (such as high salt content, high humidity, or acidic and alkaline environments), ordinary stainless steel sheet metal may still exhibit corrosion phenomena. Therefore, further improving the corrosion resistance of stainless steel sheet metal is particularly important. This article will discuss effective methods for improving the corrosion resistance of stainless steel sheet metal from aspects such as material selection, surface treatment processes, and post-maintenance.

Firstly, choosing the appropriate stainless steel material is the foundation for improving corrosion resistance. Different types of stainless steel have varying compositions and corrosion resistance. For example, 304 stainless steel is suitable for general environments, while 316 stainless steel, due to the addition of molybdenum, has stronger resistance to chloride ion corrosion and is more suitable for marine environments or chemical industries. In addition, duplex stainless steel and super austenitic stainless steel also show excellent performance in specific corrosion environments.

Secondly, surface treatment processes are crucial for enhancing corrosion resistance. Common surface treatment methods include passivation, electrolytic polishing, sandblasting, and coating treatment. Among them, passivation treatment forms a dense oxide chrome protective film on the surface of stainless steel through chemical means, which can effectively prevent the contact of metal with corrosive media; electrolytic polishing can not only improve the surface smoothness but also remove surface impurities, enhancing the material's corrosion resistance; for some special application environments, spraying corrosion-resistant coatings or electroplating with nickel, chrome, and other methods can further enhance the protective effect.

Thirdly, reasonable structural design and manufacturing processes can also indirectly enhance the corrosion resistance of stainless steel sheet metal. For example, avoiding the design of dead corners or gap structures can reduce the accumulation of corrosive media; when using welding processes, it should be controlled to prevent intergranular corrosion; surface scratches or mechanical damage should be avoided during sheet metal processing to prevent the destruction of the surface protective layer.

Finally, daily maintenance and cleaning are also important links in maintaining the corrosion resistance of stainless steel sheet metal. Regularly cleaning surface dirt, especially removing corrosive substances such as chlorides and sulfides, can significantly extend the service life of the material. Using neutral or weakly acidic cleaners, and avoiding cleaners containing chloride ions, helps maintain the surface condition of stainless steel.

In summary, to improve the corrosion resistance of stainless steel sheet metal, it is necessary to consider multiple aspects such as material selection, surface treatment, manufacturing process, and daily maintenance. Through scientific design and reasonable processing methods, stainless steel sheet metal can maintain good stability and service life in complex environments, meeting the needs of various industries for high-performance materials.