News

How to improve coaxiality in boring processing

Category:answer Publishing time:2025-11-18 16:56:35 Browse: Times

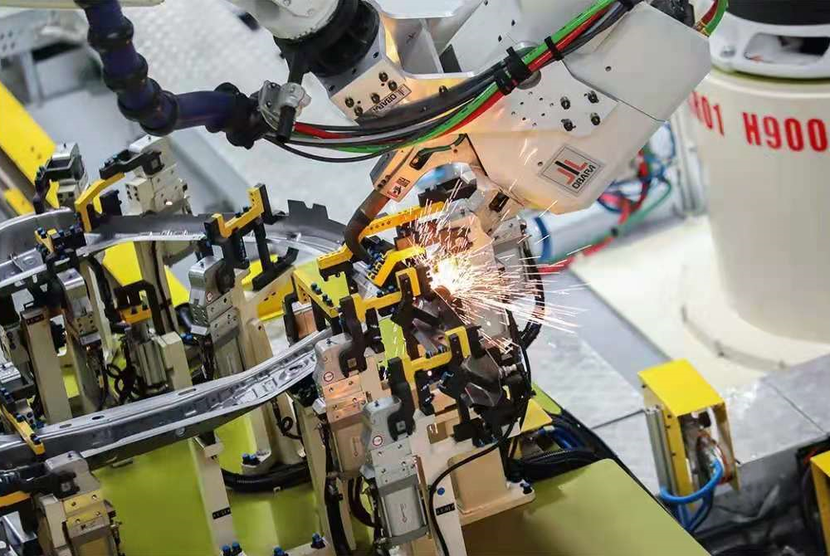

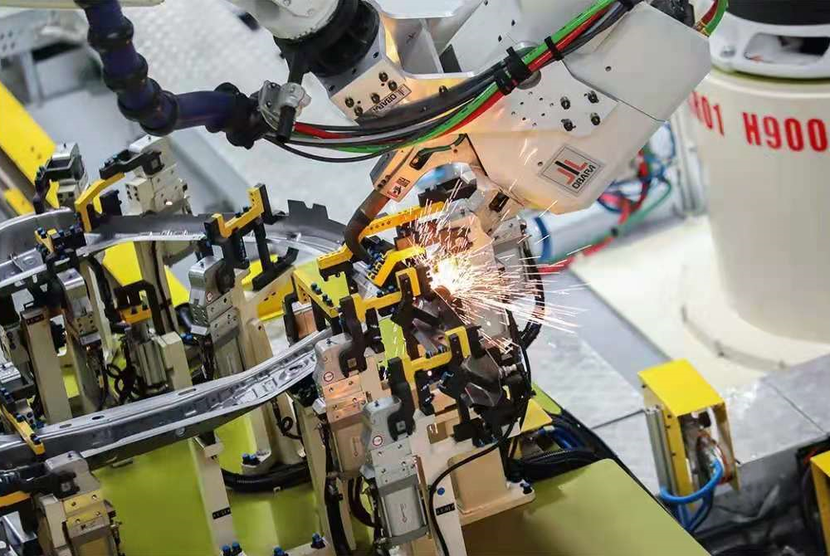

Firstly, selecting the appropriate processing equipment is the foundation for improving coaxiality. High rigidity and high-precision boring machines or machining centers can effectively reduce the influence of machine tool vibration and thermal deformation on processing accuracy. In addition, the guide rail accuracy, spindle跳动 and the stability of the feed system of the machine tool will directly affect the coaxiality of the boring hole. Therefore, it should be ensured that the equipment is in good condition before processing, and precision calibration and maintenance should be carried out regularly.

Secondly, reasonable process arrangement is crucial for coaxiality control. It is usually recommended to adopt the processing method of 'once clamping, multi-position', to minimize the number of clamping times of the workpiece, and avoid error accumulation caused by multiple positioning. When performing deep hole boring, it is advisable to adopt a step-by-step boring method, first rough boring and then fine boring, and pay attention to the reasonable setting of cutting parameters, such as appropriately reducing cutting speed and controlling feed rate, in order to reduce the impact of cutting force on the shape of the hole.

Thirdly, the selection and use of tools also directly affect the control of coaxiality. High rigidity and high-wear-resistant boring tools should be selected, and the neutral installation of the tool should be ensured. For holes with a large length-to-diameter ratio, guide sleeves or extended boring bar structures can be used to enhance the stability of the tool and reduce deflection. At the same time, the use of numerical control adjustable boring tools can achieve more precise size control and micro-adjustment, which is helpful to improve the coaxiality of the hole.

In addition, the scientific nature of the measurement means should not be ignored. Traditional coaxiality detection often uses dial indicators, micrometers, or coordinate measuring machines, but with the development of technology, more and more manufacturers are beginning to adopt on-line measurement systems to achieve real-time feedback and adjustment during the processing process. By feeding back measurement data to the numerical control system, timely correction of processing parameters can significantly improve processing accuracy.

Finally, the technical level and responsibility of the operator are also crucial. The operator should be familiar with the processing technology and equipment performance, be able to flexibly adjust process parameters according to the actual processing conditions, and maintain a rigorous work attitude during the processing process to truly achieve high-quality coaxiality control.

In summary, to improve the coaxiality in boring processing, it is necessary to consider various aspects such as equipment, technology, tools, measurement, and personnel. Only through systematic management and refined operation can we continuously break through the limit of processing accuracy and meet the high precision requirements of modern manufacturing industry for parts.

Firstly, selecting the appropriate processing equipment is the foundation for improving coaxiality. High rigidity and high-precision boring machines or machining centers can effectively reduce the influence of machine tool vibration and thermal deformation on processing accuracy. In addition, the guide rail accuracy, spindle跳动 and the stability of the feed system of the machine tool will directly affect the coaxiality of the boring hole. Therefore, it should be ensured that the equipment is in good condition before processing, and precision calibration and maintenance should be carried out regularly.

Secondly, reasonable process arrangement is crucial for coaxiality control. It is usually recommended to adopt the processing method of 'once clamping, multi-position', to minimize the number of clamping times of the workpiece, and avoid error accumulation caused by multiple positioning. When performing deep hole boring, it is advisable to adopt a step-by-step boring method, first rough boring and then fine boring, and pay attention to the reasonable setting of cutting parameters, such as appropriately reducing cutting speed and controlling feed rate, in order to reduce the impact of cutting force on the shape of the hole.

Thirdly, the selection and use of tools also directly affect the control of coaxiality. High rigidity and high-wear-resistant boring tools should be selected, and the neutral installation of the tool should be ensured. For holes with a large length-to-diameter ratio, guide sleeves or extended boring bar structures can be used to enhance the stability of the tool and reduce deflection. At the same time, the use of numerical control adjustable boring tools can achieve more precise size control and micro-adjustment, which is helpful to improve the coaxiality of the hole.

In addition, the scientific nature of the measurement means should not be ignored. Traditional coaxiality detection often uses dial indicators, micrometers, or coordinate measuring machines, but with the development of technology, more and more manufacturers are beginning to adopt on-line measurement systems to achieve real-time feedback and adjustment during the processing process. By feeding back measurement data to the numerical control system, timely correction of processing parameters can significantly improve processing accuracy.

Finally, the technical level and responsibility of the operator are also crucial. The operator should be familiar with the processing technology and equipment performance, be able to flexibly adjust process parameters according to the actual processing conditions, and maintain a rigorous work attitude during the processing process to truly achieve high-quality coaxiality control.

In summary, to improve the coaxiality in boring processing, it is necessary to consider various aspects such as equipment, technology, tools, measurement, and personnel. Only through systematic management and refined operation can we continuously break through the limit of processing accuracy and meet the high precision requirements of modern manufacturing industry for parts.