News

How coating materials can improve corrosion resistance

Category:answer Publishing time:2025-10-22 08:41:07 Browse: Times

In the development of modern industry and technology, the corrosion problem of metallic materials has always been an important factor affecting the service life, safety, and economic cost of equipment. Corrosion not only causes waste of materials but can also lead to serious safety accidents. Therefore, improving the corrosion resistance of metallic materials has become an important research direction in the engineering field. Among them, the surface modification of the metallic matrix using coating materials is one of the commonly used methods to enhance its corrosion resistance. This article will discuss how coating materials can improve the corrosion resistance of metals through physical and chemical mechanisms.

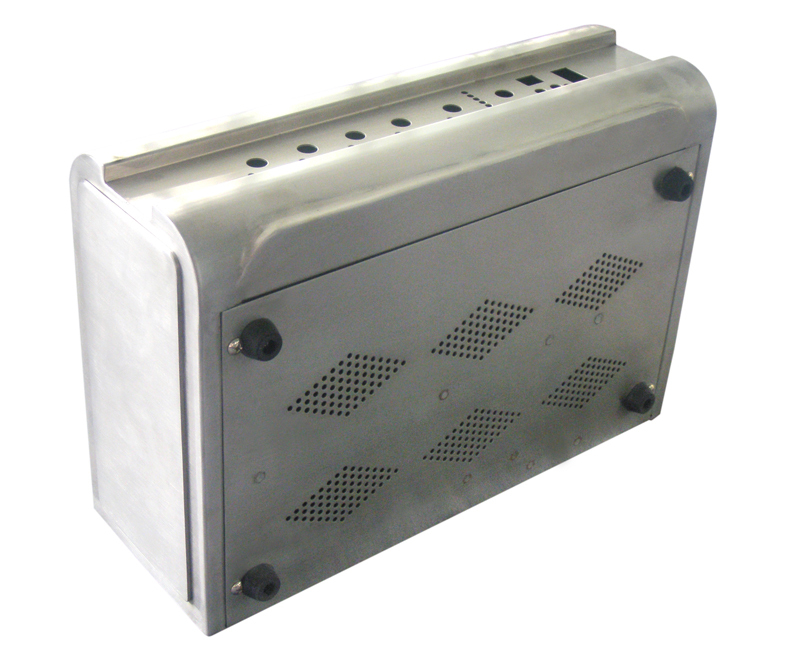

Firstly, coating materials act as a physical barrier by isolating the metallic matrix from the external corrosive environment. For example, galvanizing, nickel plating, and chrome plating are widely used in the surface treatment of ferrous materials. Zinc coating is a typical anodic protection coating, which is more reactive than iron and can undergo oxidation reactions preferentially in the corrosive environment, thereby protecting the underlying metal from corrosion. The chrome coating, with its dense structure and good chemical stability, forms a stable oxide film, effectively preventing contact between water and oxygen with the metal surface.

Secondly, certain coatings can enhance the corrosion resistance of metals by forming passivation films. For example, the chromium layer on the surface of stainless steel can rapidly form a dense chrome oxide film in the air, which has strong stability and can effectively prevent further oxidation and corrosion. In addition, nanocoating technologies such as titanium nitride (TiN) and silicon carbide (SiC) ceramics developed in recent years, due to their extremely high hardness and chemical inertness, show excellent protective properties in extreme corrosion environments.

Furthermore, the application of composite coatings is also an effective means to enhance corrosion resistance. For example, combining metal coatings with organic coatings can bring out the respective advantages to form a multi-layer protective system. The metal coating provides initial electrochemical protection or physical isolation, while the outer organic coating further enhances the overall sealing and weather resistance, thereby significantly extending the service life of the material.

In summary, coating materials can significantly improve the corrosion resistance of metallic materials through various mechanisms such as physical shielding, electrochemical protection, and the formation of passivation films. With the development of materials science and surface engineering technology, new types of coatings such as nanostructured coatings and multifunctional composite coatings continue to emerge, providing more efficient and environmentally friendly solutions to corrosion problems. In the future, as the demand for high-performance materials continues to grow, research and application of coating materials in improving corrosion resistance will have an even broader prospect.

In the development of modern industry and technology, the corrosion problem of metallic materials has always been an important factor affecting the service life, safety, and economic cost of equipment. Corrosion not only causes waste of materials but can also lead to serious safety accidents. Therefore, improving the corrosion resistance of metallic materials has become an important research direction in the engineering field. Among them, the surface modification of the metallic matrix using coating materials is one of the commonly used methods to enhance its corrosion resistance. This article will discuss how coating materials can improve the corrosion resistance of metals through physical and chemical mechanisms.

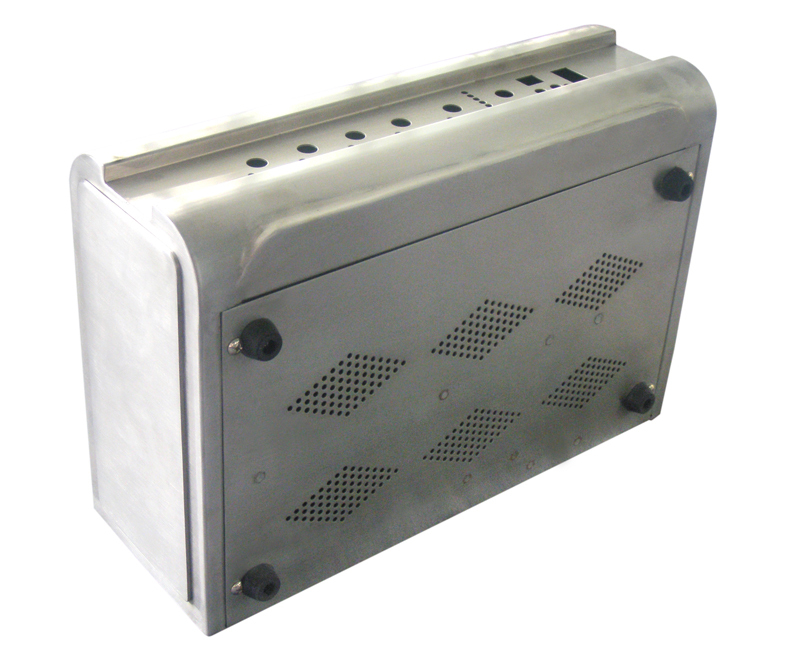

Firstly, coating materials act as a physical barrier by isolating the metallic matrix from the external corrosive environment. For example, galvanizing, nickel plating, and chrome plating are widely used in the surface treatment of ferrous materials. Zinc coating is a typical anodic protection coating, which is more reactive than iron and can undergo oxidation reactions preferentially in the corrosive environment, thereby protecting the underlying metal from corrosion. The chrome coating, with its dense structure and good chemical stability, forms a stable oxide film, effectively preventing contact between water and oxygen with the metal surface.

Secondly, certain coatings can enhance the corrosion resistance of metals by forming passivation films. For example, the chromium layer on the surface of stainless steel can rapidly form a dense chrome oxide film in the air, which has strong stability and can effectively prevent further oxidation and corrosion. In addition, nanocoating technologies such as titanium nitride (TiN) and silicon carbide (SiC) ceramics developed in recent years, due to their extremely high hardness and chemical inertness, show excellent protective properties in extreme corrosion environments.

Furthermore, the application of composite coatings is also an effective means to enhance corrosion resistance. For example, combining metal coatings with organic coatings can bring out the respective advantages to form a multi-layer protective system. The metal coating provides initial electrochemical protection or physical isolation, while the outer organic coating further enhances the overall sealing and weather resistance, thereby significantly extending the service life of the material.

In summary, coating materials can significantly improve the corrosion resistance of metallic materials through various mechanisms such as physical shielding, electrochemical protection, and the formation of passivation films. With the development of materials science and surface engineering technology, new types of coatings such as nanostructured coatings and multifunctional composite coatings continue to emerge, providing more efficient and environmentally friendly solutions to corrosion problems. In the future, as the demand for high-performance materials continues to grow, research and application of coating materials in improving corrosion resistance will have an even broader prospect.