News

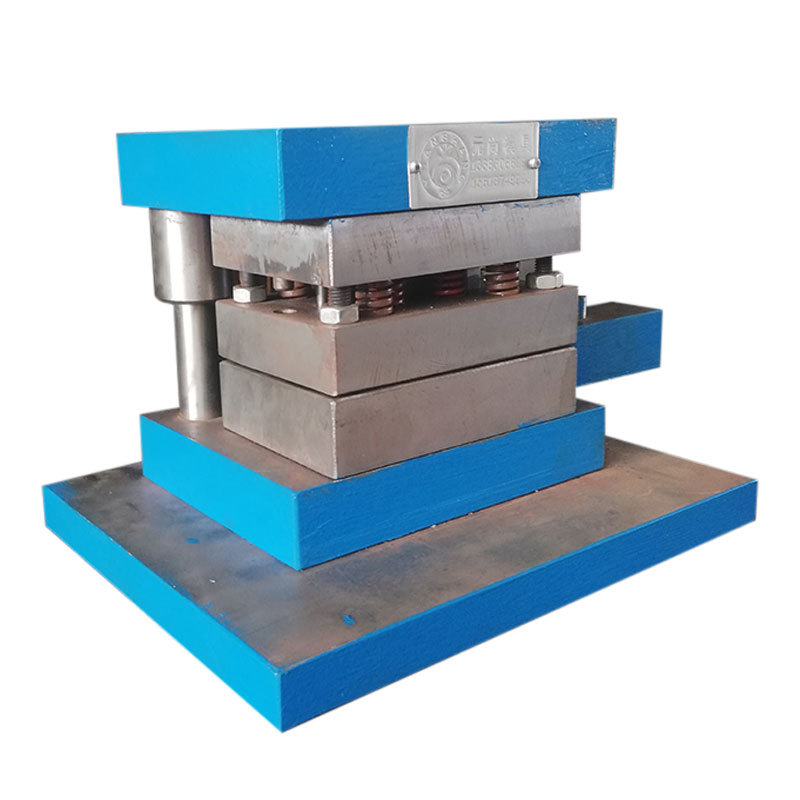

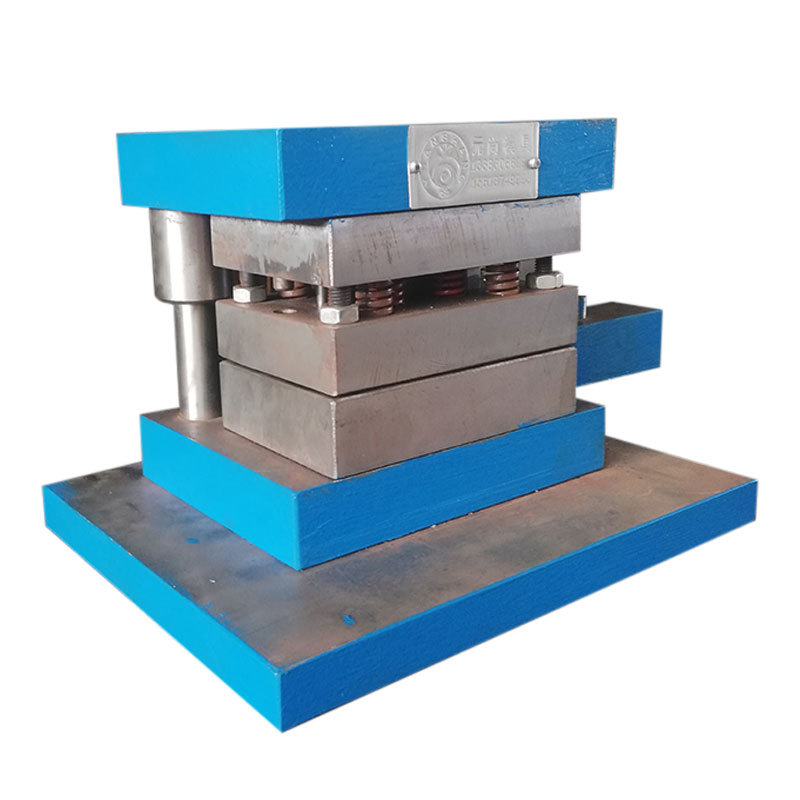

How to extend the service life of wear-resistant plate sheet metal

Category:answer Publishing time:2025-09-28 16:08:32 Browse: Times

In industrial production, wear-resistant plate sheet metal is widely used in mining machinery, construction machinery, metallurgical equipment, and other fields, and its performance directly affects the operation efficiency and service life of equipment. Due to the long-term high-intensity, high-wear, and high-impact working environment, wear-resistant plate sheet metal is prone to wear, deformation, and even fracture. Therefore, how to effectively extend the service life of wear-resistant plate sheet metal has become a focus of enterprises.

Firstly, selecting high-quality wear-resistant materials is the premise for extending the service life. Currently, common wear-resistant steel plates on the market mainly include NM360, NM400, NM450, and other grades with increasing hardness and wear resistance. Enterprises should reasonably select material grades according to specific working conditions to avoid material performance mismatch with the usage environment, resulting in resource waste or premature failure.

Secondly, reasonable structural design and processing technology are also crucial. In the design of sheet metal parts, it should be avoided to have stress concentration areas, such as sharp corners and edge holes, which are prone to be the starting points of cracks. At the same time, strict control of processing parameters such as cutting, stamping, and bending should be maintained during the processing process to avoid material internal structure damage due to improper processing, thereby reducing its wear resistance and fatigue life.

Thirdly, the application of surface treatment technology can significantly improve the wear resistance of wear-resistant plate sheet metal. For example, by forming a layer of high-hardness wear-resistant coating on the surface through thermal spraying, laser cladding, or surfacing processes, not only can the wear resistance be improved, but also the corrosion and oxidation resistance can be enhanced. In addition, an appropriate coating can also play a buffering and shock-absorbing role, reducing the direct damage to the plate from impact loads.

In addition, daily maintenance and care should not be neglected. Regularly check the wear condition of wear-resistant plate parts in the equipment, and timely replace parts that have been severely worn to prevent overall failure due to local failure. At the same time, it should be avoided to operate the equipment at overload during the operation process, control the working temperature and humidity, and reduce the adverse effects of the external environment on material properties.

Lastly, reasonable usage methods and operating habits are also important factors in extending the service life. Staff should strictly follow the equipment operation procedures for operations, and avoid abnormal wear caused by rough handling. For parts prone to wear, regular rotation and replacement of installation positions can be adopted to achieve uniform wear, thereby extending the overall service life.

In summary, extending the service life of wear-resistant plate sheet metal is a systematic project, which requires comprehensive consideration and implementation from multiple aspects such as material selection, structural design, processing technology, surface treatment, maintenance and operation specifications. Only in this way can the service efficiency of wear-resistant plate sheet metal be maximized, the maintenance cost of enterprises be reduced, and the overall operation stability of equipment be improved.

In industrial production, wear-resistant plate sheet metal is widely used in mining machinery, construction machinery, metallurgical equipment, and other fields, and its performance directly affects the operation efficiency and service life of equipment. Due to the long-term high-intensity, high-wear, and high-impact working environment, wear-resistant plate sheet metal is prone to wear, deformation, and even fracture. Therefore, how to effectively extend the service life of wear-resistant plate sheet metal has become a focus of enterprises.

Firstly, selecting high-quality wear-resistant materials is the premise for extending the service life. Currently, common wear-resistant steel plates on the market mainly include NM360, NM400, NM450, and other grades with increasing hardness and wear resistance. Enterprises should reasonably select material grades according to specific working conditions to avoid material performance mismatch with the usage environment, resulting in resource waste or premature failure.

Secondly, reasonable structural design and processing technology are also crucial. In the design of sheet metal parts, it should be avoided to have stress concentration areas, such as sharp corners and edge holes, which are prone to be the starting points of cracks. At the same time, strict control of processing parameters such as cutting, stamping, and bending should be maintained during the processing process to avoid material internal structure damage due to improper processing, thereby reducing its wear resistance and fatigue life.

Thirdly, the application of surface treatment technology can significantly improve the wear resistance of wear-resistant plate sheet metal. For example, by forming a layer of high-hardness wear-resistant coating on the surface through thermal spraying, laser cladding, or surfacing processes, not only can the wear resistance be improved, but also the corrosion and oxidation resistance can be enhanced. In addition, an appropriate coating can also play a buffering and shock-absorbing role, reducing the direct damage to the plate from impact loads.

In addition, daily maintenance and care should not be neglected. Regularly check the wear condition of wear-resistant plate parts in the equipment, and timely replace parts that have been severely worn to prevent overall failure due to local failure. At the same time, it should be avoided to operate the equipment at overload during the operation process, control the working temperature and humidity, and reduce the adverse effects of the external environment on material properties.

Lastly, reasonable usage methods and operating habits are also important factors in extending the service life. Staff should strictly follow the equipment operation procedures for operations, and avoid abnormal wear caused by rough handling. For parts prone to wear, regular rotation and replacement of installation positions can be adopted to achieve uniform wear, thereby extending the overall service life.

In summary, extending the service life of wear-resistant plate sheet metal is a systematic project, which requires comprehensive consideration and implementation from multiple aspects such as material selection, structural design, processing technology, surface treatment, maintenance and operation specifications. Only in this way can the service efficiency of wear-resistant plate sheet metal be maximized, the maintenance cost of enterprises be reduced, and the overall operation stability of equipment be improved.