News

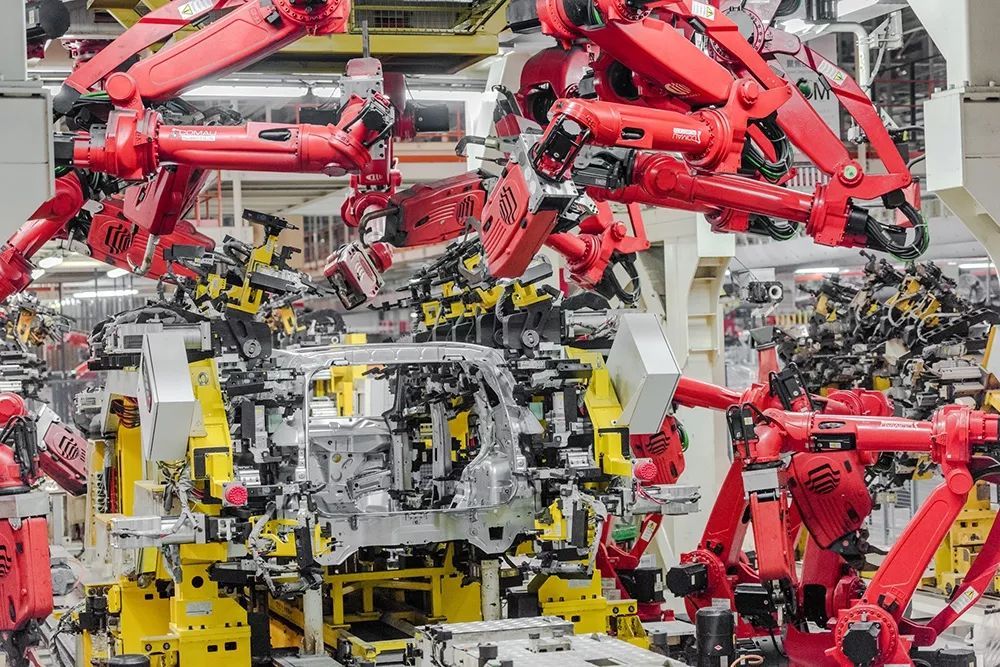

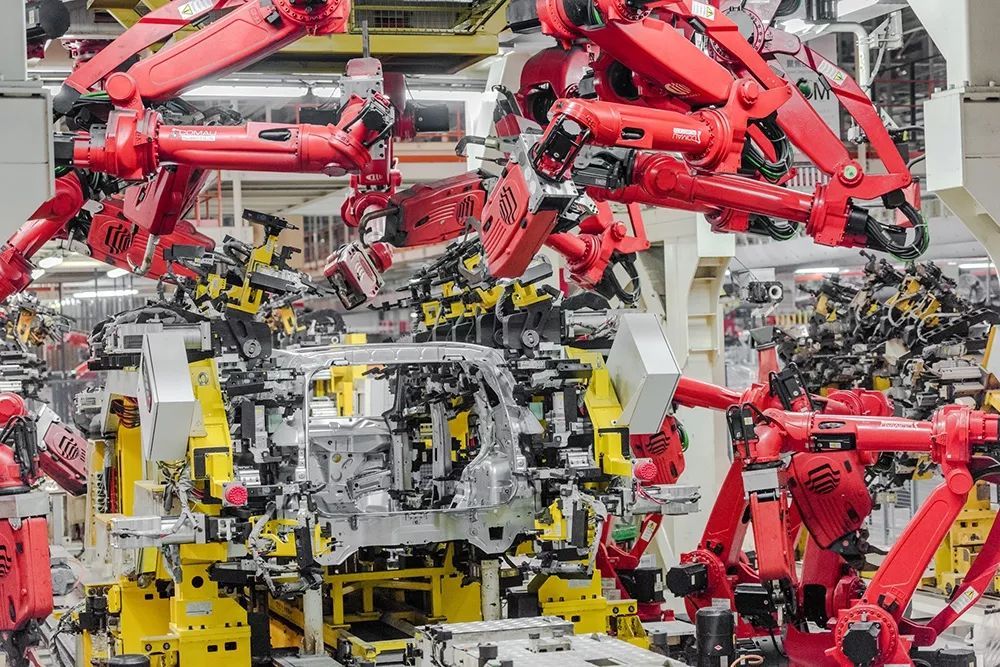

How to ensure the clarity of sheet metal stamping process

Category:answer Publishing time:2025-11-27 09:12:51 Browse: Times

One, Mold Design and Machining Accuracy

The mold is the core tool of sheet metal stamping, and its quality directly affects the stamping effect. In order to ensure the clarity of stamping, the design of the mold should accurately calculate the stamping depth and contour shape to ensure that the pattern edges are clear and the lines are distinct. At the same time, the mold material should be selected as high-hardness, wear-resistant alloy steel, and heat-treated to improve its surface hardness and wear resistance. In addition, the mold surface should be finely polished to avoid burrs or scratches that affect the integrity of the stamped pattern.

Two, Material and Thickness Selection of Sheet Material

The clarity of stamping on sheet metal is also affected by the material and thickness of the sheet material. Different metals have different plastic deformation capabilities when subjected to force, and soft materials such as aluminum plates and copper plates have better stamping effects, while hard materials such as stainless steel require higher stamping force and more precise mold matching. At the same time, overly thin sheet material may cause penetration or uneven deformation, while overly thick material may cause insufficient stamping depth, affecting clarity. Therefore, appropriate materials and thicknesses should be selected according to product requirements.

Three, Stamping Equipment and Parameter Control

Modern stamping equipment such as hydraulic presses, stamping machines, and servo presses can achieve precise pressure control and stroke adjustment, which is an important guarantee for the consistency and clarity of stamping. The reasonable stamping speed, pressure size, and holding time need to be determined through experiments, preventing over-pressure or under-pressure phenomena under the premise of ensuring the full plastic deformation of the material. In addition, using equipment with pressure sensors and displacement control can also realize real-time monitoring of the stamping process.

Four, Process Flow and Quality Inspection

Before stamping, the surface of the sheet material should be cleaned to remove oil stains, oxidation skin, and other impurities to avoid affecting the clarity of the stamping. After stamping is completed, strict quality inspection should be carried out, such as using a magnifying glass, projector, or laser scanner to detect whether the stamped pattern is complete, whether the edges are clear, and whether the depth is uniform. For mass production, it is recommended to establish a standard sample comparison system to ensure the consistency of the quality of each batch of stamping.

Conclusion

In summary, the guarantee of the clarity of stamping on sheet metal involves many aspects such as mold design, material selection, equipment control, and process management. Only through fine control at each link can the clarity and beauty of the final stamped pattern be ensured. With the development of intelligent manufacturing and precision processing technology, the stamping process of sheet metal will continue to progress towards higher efficiency and higher precision.

One, Mold Design and Machining Accuracy

The mold is the core tool of sheet metal stamping, and its quality directly affects the stamping effect. In order to ensure the clarity of stamping, the design of the mold should accurately calculate the stamping depth and contour shape to ensure that the pattern edges are clear and the lines are distinct. At the same time, the mold material should be selected as high-hardness, wear-resistant alloy steel, and heat-treated to improve its surface hardness and wear resistance. In addition, the mold surface should be finely polished to avoid burrs or scratches that affect the integrity of the stamped pattern.

Two, Material and Thickness Selection of Sheet Material

The clarity of stamping on sheet metal is also affected by the material and thickness of the sheet material. Different metals have different plastic deformation capabilities when subjected to force, and soft materials such as aluminum plates and copper plates have better stamping effects, while hard materials such as stainless steel require higher stamping force and more precise mold matching. At the same time, overly thin sheet material may cause penetration or uneven deformation, while overly thick material may cause insufficient stamping depth, affecting clarity. Therefore, appropriate materials and thicknesses should be selected according to product requirements.

Three, Stamping Equipment and Parameter Control

Modern stamping equipment such as hydraulic presses, stamping machines, and servo presses can achieve precise pressure control and stroke adjustment, which is an important guarantee for the consistency and clarity of stamping. The reasonable stamping speed, pressure size, and holding time need to be determined through experiments, preventing over-pressure or under-pressure phenomena under the premise of ensuring the full plastic deformation of the material. In addition, using equipment with pressure sensors and displacement control can also realize real-time monitoring of the stamping process.

Four, Process Flow and Quality Inspection

Before stamping, the surface of the sheet material should be cleaned to remove oil stains, oxidation skin, and other impurities to avoid affecting the clarity of the stamping. After stamping is completed, strict quality inspection should be carried out, such as using a magnifying glass, projector, or laser scanner to detect whether the stamped pattern is complete, whether the edges are clear, and whether the depth is uniform. For mass production, it is recommended to establish a standard sample comparison system to ensure the consistency of the quality of each batch of stamping.

Conclusion

In summary, the guarantee of the clarity of stamping on sheet metal involves many aspects such as mold design, material selection, equipment control, and process management. Only through fine control at each link can the clarity and beauty of the final stamped pattern be ensured. With the development of intelligent manufacturing and precision processing technology, the stamping process of sheet metal will continue to progress towards higher efficiency and higher precision.