News

How to ensure fitting accuracy in assembly processes

Category:answer Publishing time:2025-10-14 19:00:28 Browse: Times

Firstly, reasonable assembly process planning is the foundation for ensuring fitting accuracy. Before assembly, detailed assembly procedures and operation specifications should be formulated according to the structural characteristics, functional requirements, and tolerance fitting standards of the parts. For example, for parts requiring high-precision positioning, the principle of unified positioning benchmark should be given priority to avoid error accumulation caused by changes in the benchmark. In addition, the assembly sequence should be reasonably arranged to ensure that key fitting surfaces are assembled last, reducing interference to accuracy from intermediate links.

Secondly, precise measurement and detection means are an important guarantee for controlling fitting accuracy. In modern assembly processes, high-precision measuring tools and detection equipment such as coordinate measuring machines and laser interferometers are widely used to ensure that the size accuracy and form and position tolerances during assembly meet design requirements. At the same time, for key fitting parts, multiple re-measurements should be carried out before and after assembly to promptly detect and correct deviations.

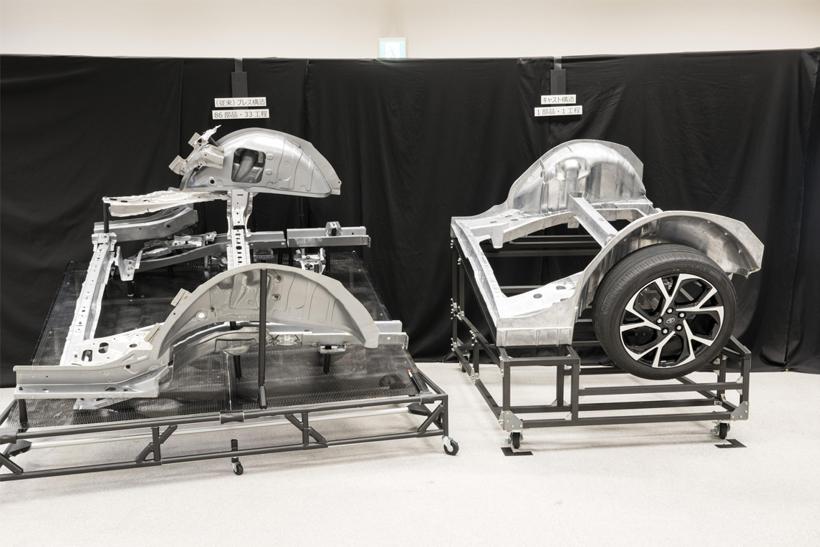

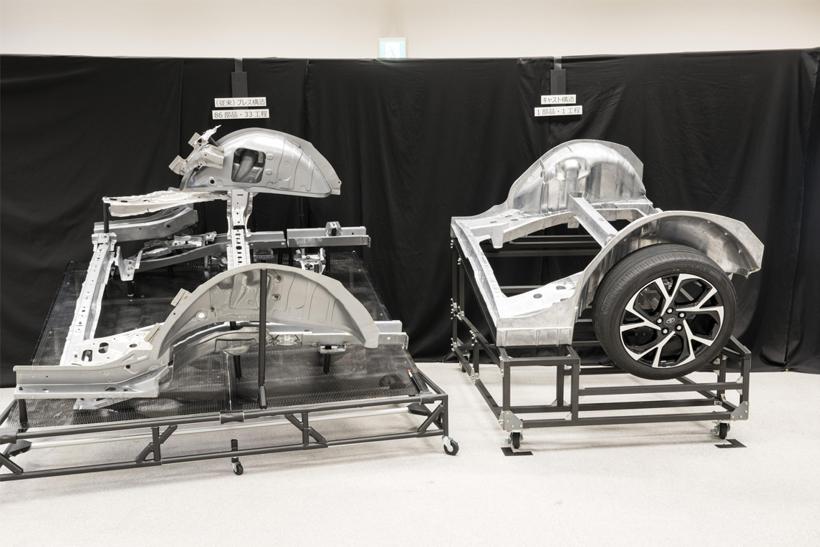

Furthermore, the selection and adjustment of fixtures and gauges play a vital role in ensuring fitting accuracy. Appropriate fixtures can effectively fix the position of parts, reduce displacement and deformation during assembly, thereby improving assembly accuracy. In high-precision assembly, adjustable fixtures or flexible fixtures are often used to allow for micro-adjustments according to the actual size of the parts, achieving the best fit state.

In addition, the technical level and responsibility of the operators directly affect the assembly accuracy. Even with advanced equipment and processes, improper operation may lead to poor fit. Therefore, enterprises should strengthen employee skill training and improve their understanding and execution ability of assembly processes. At the same time, an完善的质量控制体系 should be established to comprehensively monitor the quality of the assembly process through a combination of self-inspection, mutual inspection, and special inspection.

In summary, ensuring assembly accuracy is a systematic project that requires efforts from multiple aspects such as process planning, measurement and detection, fixture and gauge, and personnel quality. Coordination and strict control are necessary. Only in this way can high-quality and high-precision product assembly be truly realized, meeting the high standards of performance and reliability required by modern manufacturing industry.

Firstly, reasonable assembly process planning is the foundation for ensuring fitting accuracy. Before assembly, detailed assembly procedures and operation specifications should be formulated according to the structural characteristics, functional requirements, and tolerance fitting standards of the parts. For example, for parts requiring high-precision positioning, the principle of unified positioning benchmark should be given priority to avoid error accumulation caused by changes in the benchmark. In addition, the assembly sequence should be reasonably arranged to ensure that key fitting surfaces are assembled last, reducing interference to accuracy from intermediate links.

Secondly, precise measurement and detection means are an important guarantee for controlling fitting accuracy. In modern assembly processes, high-precision measuring tools and detection equipment such as coordinate measuring machines and laser interferometers are widely used to ensure that the size accuracy and form and position tolerances during assembly meet design requirements. At the same time, for key fitting parts, multiple re-measurements should be carried out before and after assembly to promptly detect and correct deviations.

Furthermore, the selection and adjustment of fixtures and gauges play a vital role in ensuring fitting accuracy. Appropriate fixtures can effectively fix the position of parts, reduce displacement and deformation during assembly, thereby improving assembly accuracy. In high-precision assembly, adjustable fixtures or flexible fixtures are often used to allow for micro-adjustments according to the actual size of the parts, achieving the best fit state.

In addition, the technical level and responsibility of the operators directly affect the assembly accuracy. Even with advanced equipment and processes, improper operation may lead to poor fit. Therefore, enterprises should strengthen employee skill training and improve their understanding and execution ability of assembly processes. At the same time, an完善的质量控制体系 should be established to comprehensively monitor the quality of the assembly process through a combination of self-inspection, mutual inspection, and special inspection.

In summary, ensuring assembly accuracy is a systematic project that requires efforts from multiple aspects such as process planning, measurement and detection, fixture and gauge, and personnel quality. Coordination and strict control are necessary. Only in this way can high-quality and high-precision product assembly be truly realized, meeting the high standards of performance and reliability required by modern manufacturing industry.