News

How to design the pouring system in the casting process

Category:answer Publishing time:2025-12-01 19:25:05 Browse: Times

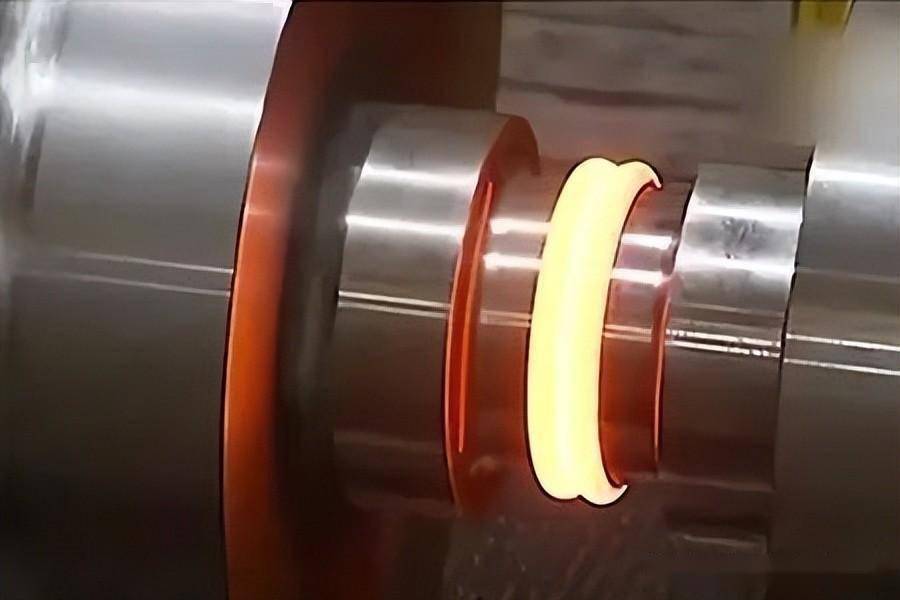

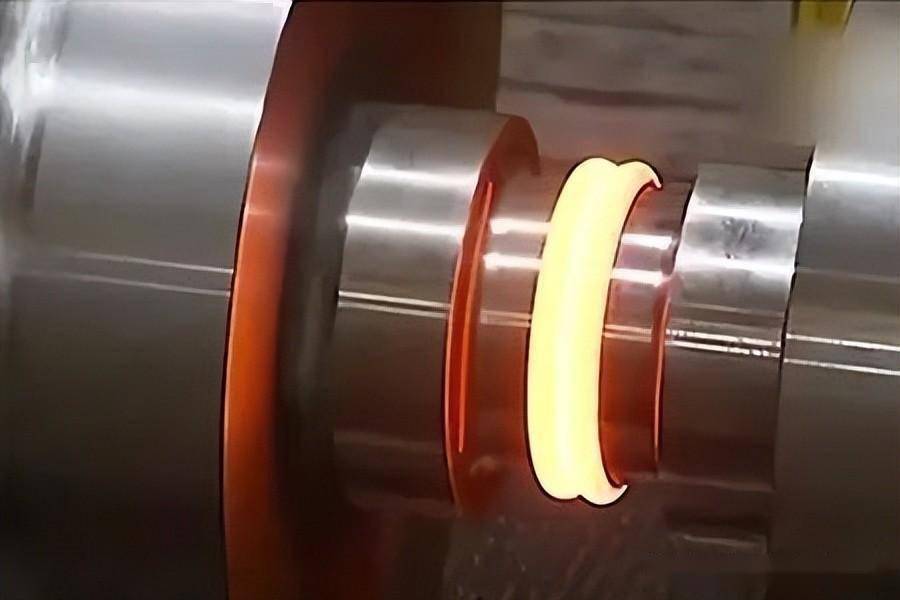

In the casting process, the pouring system is a key component to ensure the quality of castings. Its main function is to smoothly introduce molten metal into the mold cavity while controlling the flow state of the metal liquid, to avoid defects such as blowholes, shrinkage holes, and inclusions. Therefore, the reasonable design of the pouring system is of great significance to improve the yield and performance of castings.

One, Composition of Casting System

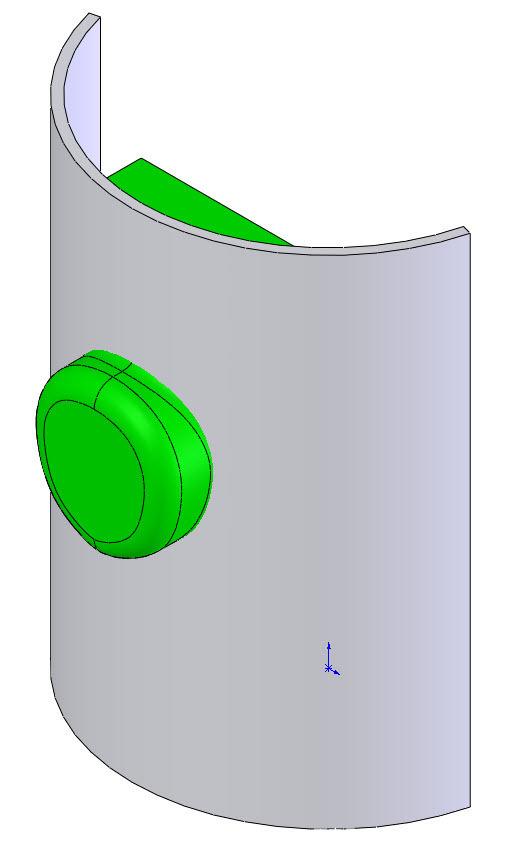

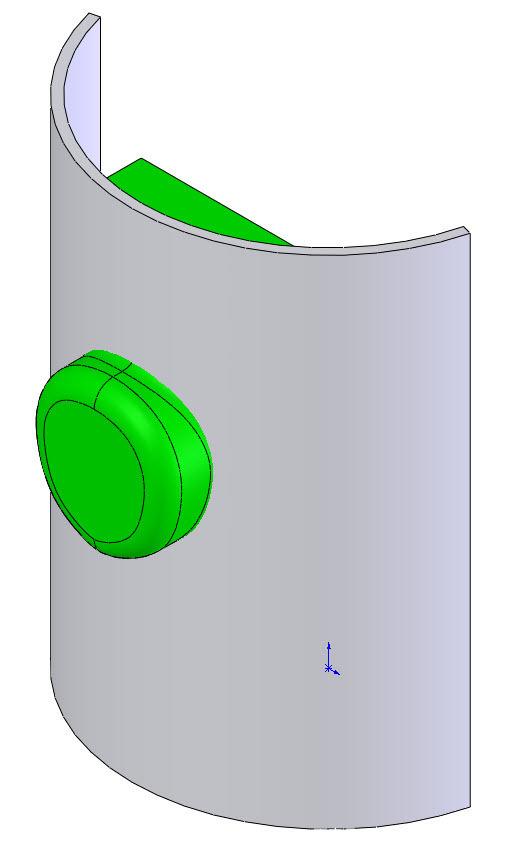

A complete casting system usually consists of four parts: sprue cup, straight runner, transverse runner, and inner runner:

- Sprue cup: used to receive metal liquid and prevent splashing, playing a buffering role;

- Straight runner: introduces metal liquid from the sprue cup to the depth of the mold;

- Transverse runner: connects the straight runner with the inner runner, helping to distribute the metal liquid;

- Inner runner: introduces metal liquid into the mold cavity, directly affecting the filling state of the metal liquid.

Two, Basic Principles of Casting System Design

1. Ensure Smooth Filling of Metal Liquid

The casting system should be designed in a form that reduces the impact and turbulence of the metal liquid, avoiding oxidation inclusions and blowholes caused by excessive flow rate or sudden direction changes.

2. Achieve Sequential or Simultaneous Solidification

According to the casting structure and alloy characteristics, a suitable solidification method should be selected to reduce shrinkage and porosity defects. The thick and large areas should solidify last and be supplemented by risers.

3. Reasonably Selecting Casting Position and Parting Surface

The casting system should be located at the thickest part of the casting or at a position convenient for shrinkage compensation, while also considering the convenience of mold manufacturing and cleaning.

4. Control the Flow Rate and Flow of Metal Liquid

By calculating the inner runner cross-sectional area, the inflow speed of the metal liquid is controlled to ensure that the filling is sufficient and the mold cavity is not damaged.

5. Facilitate Exhausting and Dredging

The casting system should be designed with good exhaust channels to prevent gas retention. Filters or slag collection bags should be set up when necessary to remove impurities from the metal liquid.

Three, Steps of Casting System Design

1. Analyzing the Casting Structure and Technical Requirements

Defining basic information such as material type, casting size, wall thickness distribution, and quality requirements.

2. Determining the Casting Process Plan

Including the selection of sand casting, metal mold casting, or precision casting, as well as determining the parting method and casting position.

3. Designing the Casting System Type

Common types include top injection, bottom injection, stepped, and side injection, etc. Bottom injection is suitable for thin-walled complex parts, while top injection is suitable for thick and simple parts.

4. Parameter Calculation

Including total cross-sectional area, segment ratios, and flow control, optimization design is usually carried out using empirical formulas or simulation software.

5. Verification by Simulation Software

Use casting simulation software (such as ProCAST, AnyCasting) to simulate the filling, temperature field, and solidification process during the casting process to optimize the system layout.

Four, Conclusion

In summary, the design of the casting system is a systematic project that requires comprehensive consideration of factors such as casting structure, material characteristics, and production processes. With the development of computer technology, numerical simulation is increasingly applied in the design of casting systems, providing strong support for achieving efficient and high-quality casting. Only by scientifically and reasonably designing the casting system can the quality of castings be effectively improved, the scrap rate reduced, and the competitiveness of casting enterprises enhanced.

In the casting process, the pouring system is a key component to ensure the quality of castings. Its main function is to smoothly introduce molten metal into the mold cavity while controlling the flow state of the metal liquid, to avoid defects such as blowholes, shrinkage holes, and inclusions. Therefore, the reasonable design of the pouring system is of great significance to improve the yield and performance of castings.

One, Composition of Casting System

A complete casting system usually consists of four parts: sprue cup, straight runner, transverse runner, and inner runner:

- Sprue cup: used to receive metal liquid and prevent splashing, playing a buffering role;

- Straight runner: introduces metal liquid from the sprue cup to the depth of the mold;

- Transverse runner: connects the straight runner with the inner runner, helping to distribute the metal liquid;

- Inner runner: introduces metal liquid into the mold cavity, directly affecting the filling state of the metal liquid.

Two, Basic Principles of Casting System Design

1. Ensure Smooth Filling of Metal Liquid

The casting system should be designed in a form that reduces the impact and turbulence of the metal liquid, avoiding oxidation inclusions and blowholes caused by excessive flow rate or sudden direction changes.

2. Achieve Sequential or Simultaneous Solidification

According to the casting structure and alloy characteristics, a suitable solidification method should be selected to reduce shrinkage and porosity defects. The thick and large areas should solidify last and be supplemented by risers.

3. Reasonably Selecting Casting Position and Parting Surface

The casting system should be located at the thickest part of the casting or at a position convenient for shrinkage compensation, while also considering the convenience of mold manufacturing and cleaning.

4. Control the Flow Rate and Flow of Metal Liquid

By calculating the inner runner cross-sectional area, the inflow speed of the metal liquid is controlled to ensure that the filling is sufficient and the mold cavity is not damaged.

5. Facilitate Exhausting and Dredging

The casting system should be designed with good exhaust channels to prevent gas retention. Filters or slag collection bags should be set up when necessary to remove impurities from the metal liquid.

Three, Steps of Casting System Design

1. Analyzing the Casting Structure and Technical Requirements

Defining basic information such as material type, casting size, wall thickness distribution, and quality requirements.

2. Determining the Casting Process Plan

Including the selection of sand casting, metal mold casting, or precision casting, as well as determining the parting method and casting position.

3. Designing the Casting System Type

Common types include top injection, bottom injection, stepped, and side injection, etc. Bottom injection is suitable for thin-walled complex parts, while top injection is suitable for thick and simple parts.

4. Parameter Calculation

Including total cross-sectional area, segment ratios, and flow control, optimization design is usually carried out using empirical formulas or simulation software.

5. Verification by Simulation Software

Use casting simulation software (such as ProCAST, AnyCasting) to simulate the filling, temperature field, and solidification process during the casting process to optimize the system layout.

Four, Conclusion

In summary, the design of the casting system is a systematic project that requires comprehensive consideration of factors such as casting structure, material characteristics, and production processes. With the development of computer technology, numerical simulation is increasingly applied in the design of casting systems, providing strong support for achieving efficient and high-quality casting. Only by scientifically and reasonably designing the casting system can the quality of castings be effectively improved, the scrap rate reduced, and the competitiveness of casting enterprises enhanced.