News

How to control the shrinkage rate of zinc alloy

Category:answer Publishing time:2025-10-01 02:58:05 Browse: Times

Zinc alloy is widely used in the manufacture of precision die castings in the automotive, electronic, and construction industries due to its excellent casting properties, good mechanical strength, and corrosion resistance. However, during the die casting process, zinc alloy will undergo volume shrinkage during the cooling and solidification process. If not effectively controlled, it is easy to cause defects such as shrinkage holes and shrinkage porosity in the casting, which will affect the quality and performance of the product. Therefore, controlling the shrinkage rate of zinc alloy is a key link in improving the quality of die castings.

One, Basic Principles of Zinc Alloy Shrinkage Rate

During the solidification process, metals usually experience three stages of volume change: liquid shrinkage, solidification shrinkage, and solid shrinkage. Zinc alloys are no exception. Liquid shrinkage occurs between the pouring temperature and the solidification start temperature; solidification shrinkage occurs during the transition from liquid to solid; while solid shrinkage is the volume shrinkage of the metal as it continues to cool to room temperature after complete solidification. Among them, solidification shrinkage has the greatest impact on internal defects of the casting.

Zinc alloys have a relatively short solidification temperature range and belong to near-eutectic alloys, which have good fluidity and low shrinkage tendency. However, they still need to be controlled by reasonable process to further reduce the negative impact of shrinkage.

Two, Factors Affecting the Shrinkage Rate of Zinc Alloys

1. Chemical composition: The addition of elements such as aluminum, copper, and magnesium in zinc alloys affects their crystallization behavior and shrinkage characteristics. For example, an increase in aluminum content can improve the fluidity of the alloy and reduce solidification shrinkage.

2. Cooling speed: The faster the cooling speed, the faster the metal solidifies, which helps to reduce the shrinkage amount during the liquid and solidification stages. However, rapid cooling may lead to increased internal stress.

3. Mold design: Reasonable mold structure, gating position, and riser design can effectively guide metal flow, ensure the unobstructed shrinkage compensation channel, and reduce the risk of shrinkage holes.

4. Die-casting process parameters: Factors such as injection pressure, filling speed, and mold temperature will affect the filling and solidification behavior of the metal.

Three, Technical Measures for Controlling the Shrinkage Rate of Zinc Alloys

To effectively control the shrinkage rate of zinc alloys and improve casting quality, the following technical measures can be taken:

- Optimize alloy composition: By precisely controlling the proportion of elements such as aluminum and copper in zinc alloys, they can have the minimum shrinkage tendency while ensuring performance.

- Improve mold design: Reasonably arrange the gating system and riser to ensure uniform filling of the metal liquid in the mold and effective shrinkage compensation, avoiding local overheating or uneven cooling.

- Adopt high-pressure die-casting process: Increasing the injection pressure helps to compact the metal liquid, reduce shrinkage holes and shrinkage porosity, and improve the density of the casting.

- Control mold temperature: Maintaining the mold temperature within an appropriate range (generally 150~200℃) helps with the smooth filling and uniform cooling of the metal liquid.

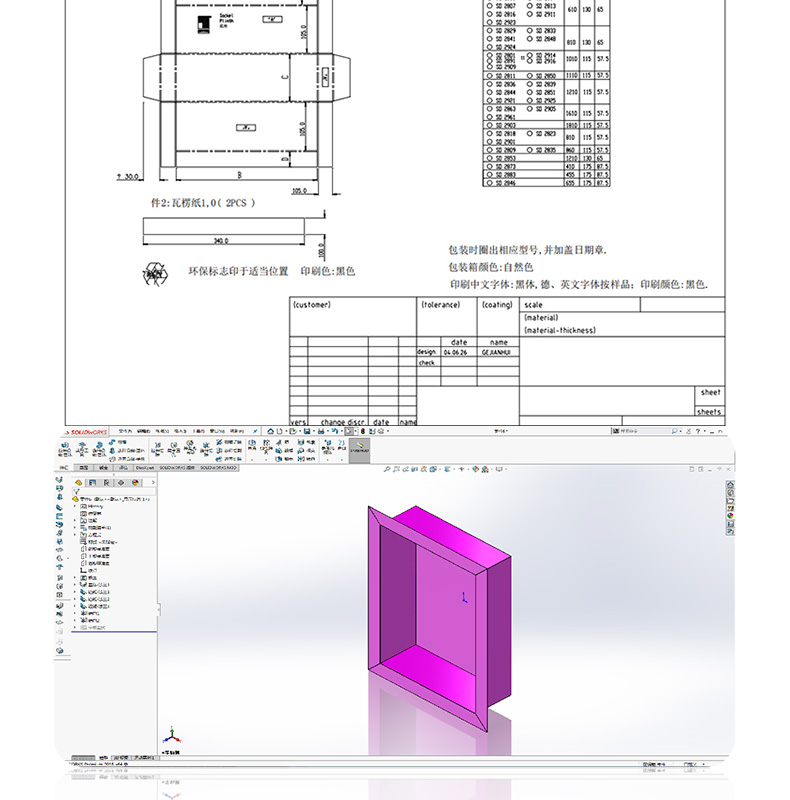

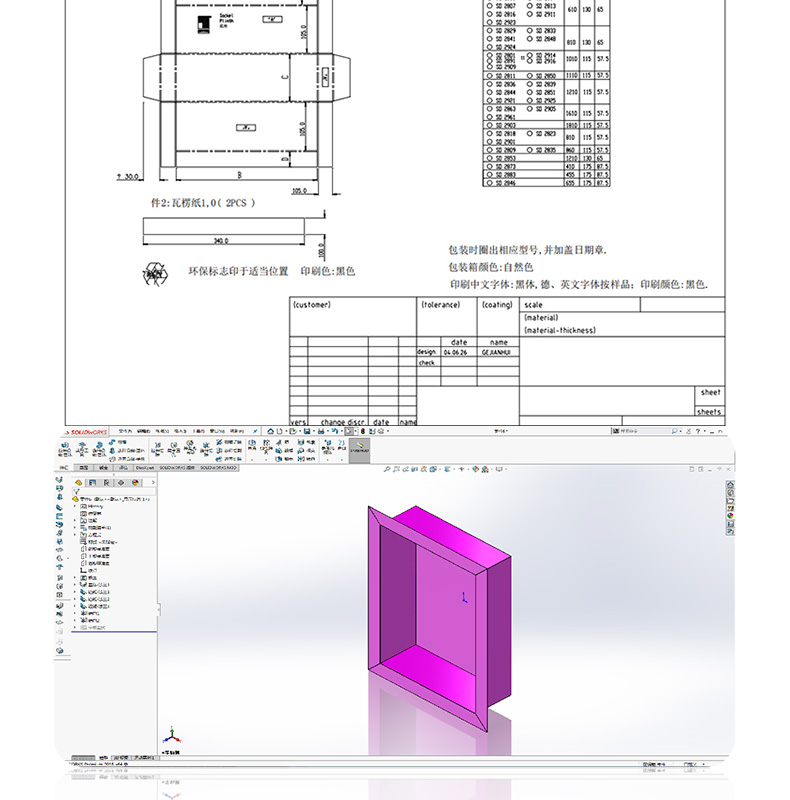

- Use simulation software for prediction: Utilize casting simulation software (such as MAGMASoft, ProCAST, etc.) to predict the location of shrinkage defects in advance, providing a basis for process optimization.

Four, Conclusion

In summary, although zinc alloys have good casting properties during the die-casting process, the shrinkage problem should not be ignored. Comprehensive control over factors such as alloy composition, mold design, and process parameters can effectively reduce shrinkage rates and improve casting quality and yield. With the continuous development of casting technology, the application prospects of zinc alloys will be broader, and their shrinkage control methods will continue to be optimized in the direction of intelligence and greenization in the future.

Zinc alloy is widely used in the manufacture of precision die castings in the automotive, electronic, and construction industries due to its excellent casting properties, good mechanical strength, and corrosion resistance. However, during the die casting process, zinc alloy will undergo volume shrinkage during the cooling and solidification process. If not effectively controlled, it is easy to cause defects such as shrinkage holes and shrinkage porosity in the casting, which will affect the quality and performance of the product. Therefore, controlling the shrinkage rate of zinc alloy is a key link in improving the quality of die castings.

One, Basic Principles of Zinc Alloy Shrinkage Rate

During the solidification process, metals usually experience three stages of volume change: liquid shrinkage, solidification shrinkage, and solid shrinkage. Zinc alloys are no exception. Liquid shrinkage occurs between the pouring temperature and the solidification start temperature; solidification shrinkage occurs during the transition from liquid to solid; while solid shrinkage is the volume shrinkage of the metal as it continues to cool to room temperature after complete solidification. Among them, solidification shrinkage has the greatest impact on internal defects of the casting.

Zinc alloys have a relatively short solidification temperature range and belong to near-eutectic alloys, which have good fluidity and low shrinkage tendency. However, they still need to be controlled by reasonable process to further reduce the negative impact of shrinkage.

Two, Factors Affecting the Shrinkage Rate of Zinc Alloys

1. Chemical composition: The addition of elements such as aluminum, copper, and magnesium in zinc alloys affects their crystallization behavior and shrinkage characteristics. For example, an increase in aluminum content can improve the fluidity of the alloy and reduce solidification shrinkage.

2. Cooling speed: The faster the cooling speed, the faster the metal solidifies, which helps to reduce the shrinkage amount during the liquid and solidification stages. However, rapid cooling may lead to increased internal stress.

3. Mold design: Reasonable mold structure, gating position, and riser design can effectively guide metal flow, ensure the unobstructed shrinkage compensation channel, and reduce the risk of shrinkage holes.

4. Die-casting process parameters: Factors such as injection pressure, filling speed, and mold temperature will affect the filling and solidification behavior of the metal.

Three, Technical Measures for Controlling the Shrinkage Rate of Zinc Alloys

To effectively control the shrinkage rate of zinc alloys and improve casting quality, the following technical measures can be taken:

- Optimize alloy composition: By precisely controlling the proportion of elements such as aluminum and copper in zinc alloys, they can have the minimum shrinkage tendency while ensuring performance.

- Improve mold design: Reasonably arrange the gating system and riser to ensure uniform filling of the metal liquid in the mold and effective shrinkage compensation, avoiding local overheating or uneven cooling.

- Adopt high-pressure die-casting process: Increasing the injection pressure helps to compact the metal liquid, reduce shrinkage holes and shrinkage porosity, and improve the density of the casting.

- Control mold temperature: Maintaining the mold temperature within an appropriate range (generally 150~200℃) helps with the smooth filling and uniform cooling of the metal liquid.

- Use simulation software for prediction: Utilize casting simulation software (such as MAGMASoft, ProCAST, etc.) to predict the location of shrinkage defects in advance, providing a basis for process optimization.

Four, Conclusion

In summary, although zinc alloys have good casting properties during the die-casting process, the shrinkage problem should not be ignored. Comprehensive control over factors such as alloy composition, mold design, and process parameters can effectively reduce shrinkage rates and improve casting quality and yield. With the continuous development of casting technology, the application prospects of zinc alloys will be broader, and their shrinkage control methods will continue to be optimized in the direction of intelligence and greenization in the future.