News

How to control the roughness in the bending wire finishing process

Category:answer Publishing time:2025-09-04 18:54:59 Browse: Times

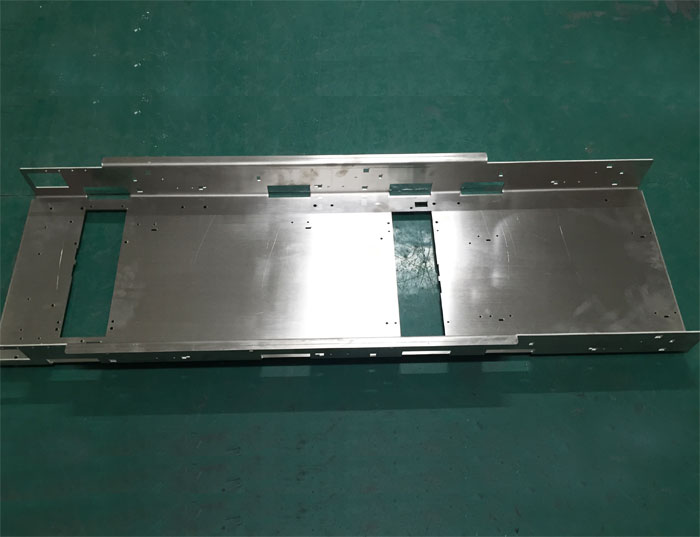

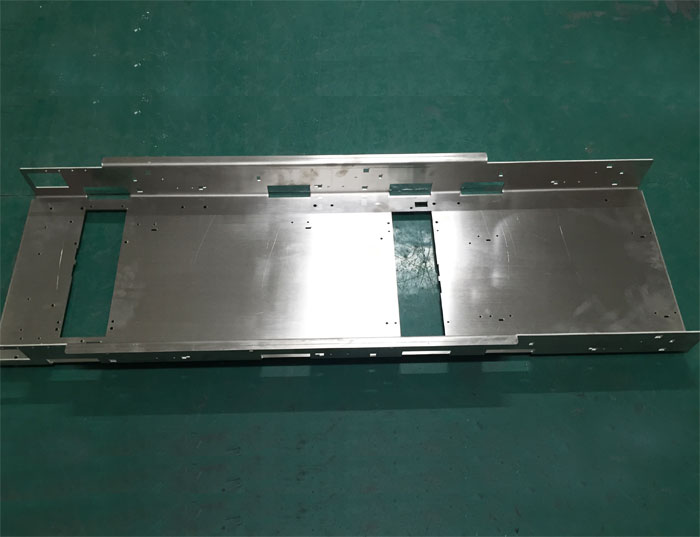

Bending wire finishing is a common metal surface treatment process, widely used in home appliances, electronic products, building decoration and other fields. This process not only enhances the aesthetic appeal of the product, but also improves its wear resistance and corrosion resistance. During the actual production process, surface roughness is one of the important parameters for evaluating the quality of wire drawing, directly affecting the tactile feel, visual effect, and subsequent coating or bonding performance of the product. Therefore, how to effectively control the surface roughness during the bending wire finishing process has become a key issue in process control.

1. Main factors affecting surface roughness

1. Sandpaper grit selection

The fineness of the sandpaper (i.e., the grit) is the most direct factor affecting surface roughness. Coarse grit sandpaper (such as 80#, 120#) will produce larger surface undulations, suitable for rough wire drawing; while fine grit sandpaper (such as 180#, 240#) can obtain a more delicate texture and a lower roughness value. Therefore, it is crucial to choose the sandpaper grit reasonably according to product requirements.

2. Matching of wire drawing speed and feeding speed

The coordination between the running speed of the sandpaper and the feeding speed of the workpiece during the wire drawing process will also affect the final surface roughness. Too fast speed may cause uneven surface scratches and a higher roughness value; while too slow speed will reduce production efficiency and even lead to local over-grinding. Therefore, in actual operation, optimization and adjustment should be made according to material characteristics and equipment performance.

3. Wire drawing direction and texture design

Different wire drawing directions (such as straight lines, cross lines, circular lines, etc.) will affect the surface luster and feel. Generally, unidirectional wire drawing is more likely to obtain a higher consistency of roughness, while cross wire drawing may cause local roughness to increase. Therefore, the texture direction should be clarified in the design stage, and combined with process parameters for control.

4. Material characteristics and pretreatment quality

Different materials of sheet metal (such as stainless steel, aluminum plate, galvanized plate, etc.) have different reactions to wire drawing, and surface hardness, plasticity, etc. will affect the final roughness. In addition, whether the workpiece surface has oil stains, oxidation layers, and other impurities will also affect the wire drawing effect. Therefore, appropriate cleaning and surface pretreatment should be carried out before wire drawing to ensure stable wire drawing quality.

Measures to improve the accuracy of surface roughness control

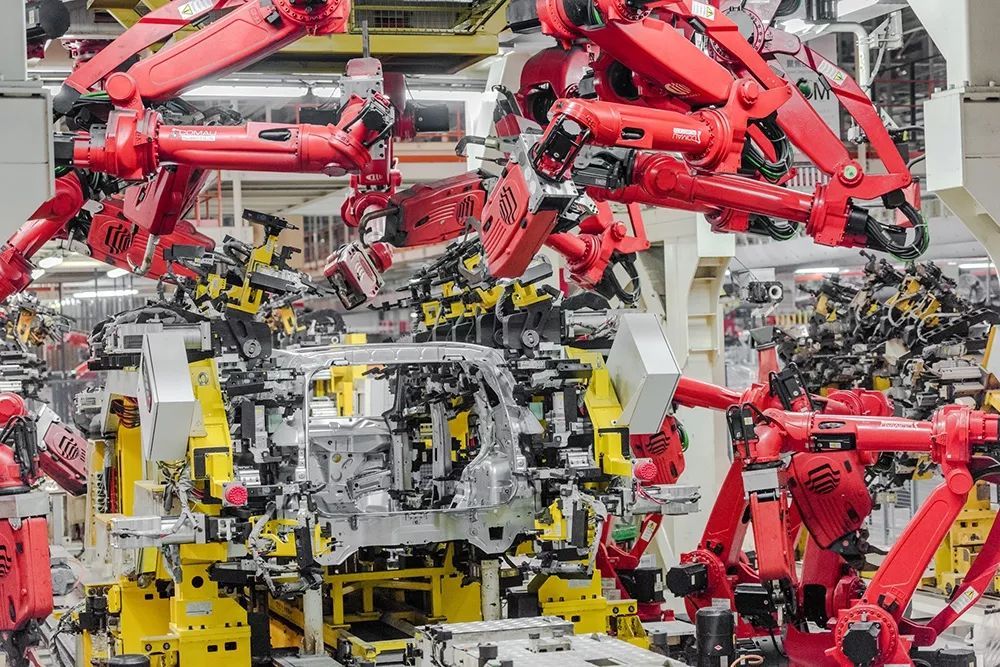

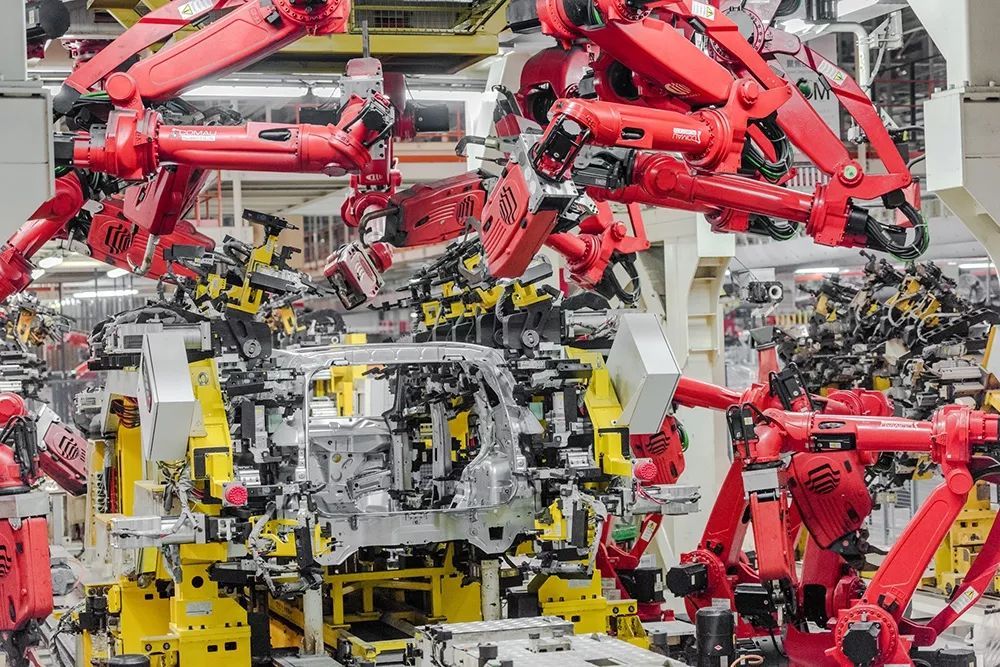

1. Use of high-precision wire drawing equipment

Modern wire drawing equipment has widely adopted numerical control technology, which can accurately control parameters such as wire drawing pressure, speed, and direction, thereby effectively improving surface consistency and roughness control ability.

2. Regular replacement and inspection of sandpaper

Sandpaper is prone to wear or clog during use, which leads to a decrease in cutting ability and thus affects the surface smoothness. Therefore, a reasonable replacement cycle should be established according to the frequency of use and material characteristics to ensure that the sandpaper is always in good condition.

3. Introduction of surface roughness detection system

Introducing on-line roughness detection devices in key processes can enable real-time monitoring of surface quality, timely adjustment of process parameters, and avoid the production of batch defective products.

Conclusion

The control of surface roughness in sheet metal wire drawing technology is a systematic project, involving materials, equipment, and processes in many aspects. Only by fully understanding the influencing factors, combining scientific management methods, and advanced detection means, can we truly achieve precise control of surface roughness, thereby improving product quality and market competitiveness.

In actual production practice, enterprises should continuously optimize process parameters, strengthen personnel training and equipment maintenance, and promote the development of sheet metal wire drawing technology towards high quality and high efficiency.

Bending wire finishing is a common metal surface treatment process, widely used in home appliances, electronic products, building decoration and other fields. This process not only enhances the aesthetic appeal of the product, but also improves its wear resistance and corrosion resistance. During the actual production process, surface roughness is one of the important parameters for evaluating the quality of wire drawing, directly affecting the tactile feel, visual effect, and subsequent coating or bonding performance of the product. Therefore, how to effectively control the surface roughness during the bending wire finishing process has become a key issue in process control.

1. Main factors affecting surface roughness

1. Sandpaper grit selection

The fineness of the sandpaper (i.e., the grit) is the most direct factor affecting surface roughness. Coarse grit sandpaper (such as 80#, 120#) will produce larger surface undulations, suitable for rough wire drawing; while fine grit sandpaper (such as 180#, 240#) can obtain a more delicate texture and a lower roughness value. Therefore, it is crucial to choose the sandpaper grit reasonably according to product requirements.

2. Matching of wire drawing speed and feeding speed

The coordination between the running speed of the sandpaper and the feeding speed of the workpiece during the wire drawing process will also affect the final surface roughness. Too fast speed may cause uneven surface scratches and a higher roughness value; while too slow speed will reduce production efficiency and even lead to local over-grinding. Therefore, in actual operation, optimization and adjustment should be made according to material characteristics and equipment performance.

3. Wire drawing direction and texture design

Different wire drawing directions (such as straight lines, cross lines, circular lines, etc.) will affect the surface luster and feel. Generally, unidirectional wire drawing is more likely to obtain a higher consistency of roughness, while cross wire drawing may cause local roughness to increase. Therefore, the texture direction should be clarified in the design stage, and combined with process parameters for control.

4. Material characteristics and pretreatment quality

Different materials of sheet metal (such as stainless steel, aluminum plate, galvanized plate, etc.) have different reactions to wire drawing, and surface hardness, plasticity, etc. will affect the final roughness. In addition, whether the workpiece surface has oil stains, oxidation layers, and other impurities will also affect the wire drawing effect. Therefore, appropriate cleaning and surface pretreatment should be carried out before wire drawing to ensure stable wire drawing quality.

Measures to improve the accuracy of surface roughness control

1. Use of high-precision wire drawing equipment

Modern wire drawing equipment has widely adopted numerical control technology, which can accurately control parameters such as wire drawing pressure, speed, and direction, thereby effectively improving surface consistency and roughness control ability.

2. Regular replacement and inspection of sandpaper

Sandpaper is prone to wear or clog during use, which leads to a decrease in cutting ability and thus affects the surface smoothness. Therefore, a reasonable replacement cycle should be established according to the frequency of use and material characteristics to ensure that the sandpaper is always in good condition.

3. Introduction of surface roughness detection system

Introducing on-line roughness detection devices in key processes can enable real-time monitoring of surface quality, timely adjustment of process parameters, and avoid the production of batch defective products.

Conclusion

The control of surface roughness in sheet metal wire drawing technology is a systematic project, involving materials, equipment, and processes in many aspects. Only by fully understanding the influencing factors, combining scientific management methods, and advanced detection means, can we truly achieve precise control of surface roughness, thereby improving product quality and market competitiveness.

In actual production practice, enterprises should continuously optimize process parameters, strengthen personnel training and equipment maintenance, and promote the development of sheet metal wire drawing technology towards high quality and high efficiency.