News

How to control the flatness of cold rolled steel sheet metal

Category:answer Publishing time:2025-11-20 08:47:53 Browse: Times

Cold rolled steel plates are widely used in the fields of automotive manufacturing, home appliances, electronic equipment, and precision instruments due to their smooth surface, even thickness, and excellent mechanical properties. During the sheet metal processing process, the flatness of the plates directly affects the appearance quality, assembly accuracy, and performance of the final product. Therefore, how to effectively control the flatness of cold rolled steel plates during sheet metal processing is a very critical technical issue.

First, Influencing factors of flatness

1. Raw material quality: Cold-rolled steel plates themselves may have minor waves, curvature, or sickle bend, etc., which will be magnified in subsequent processing, affecting the flatness of the finished product.

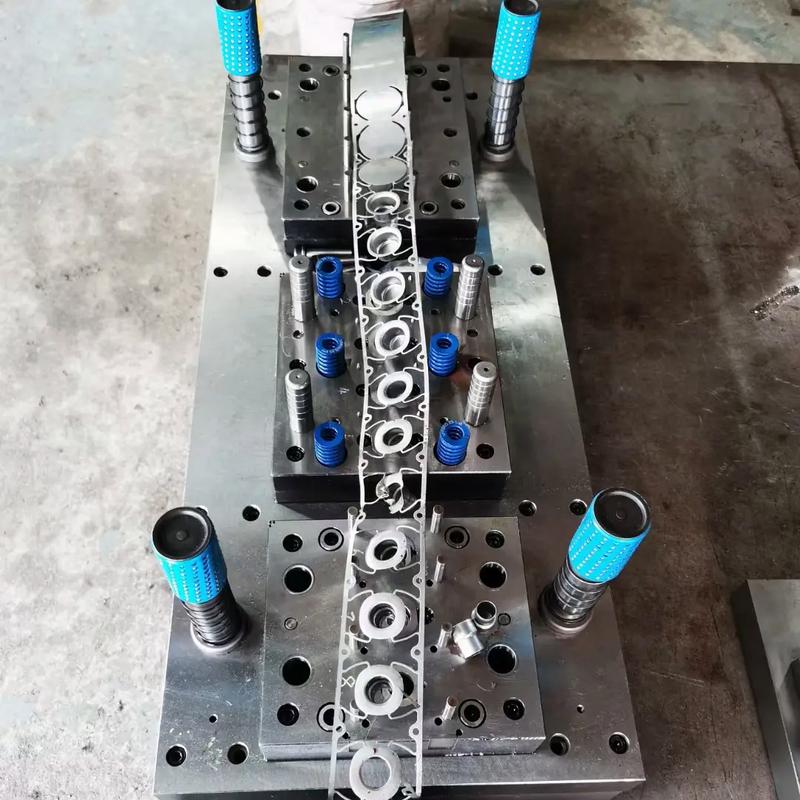

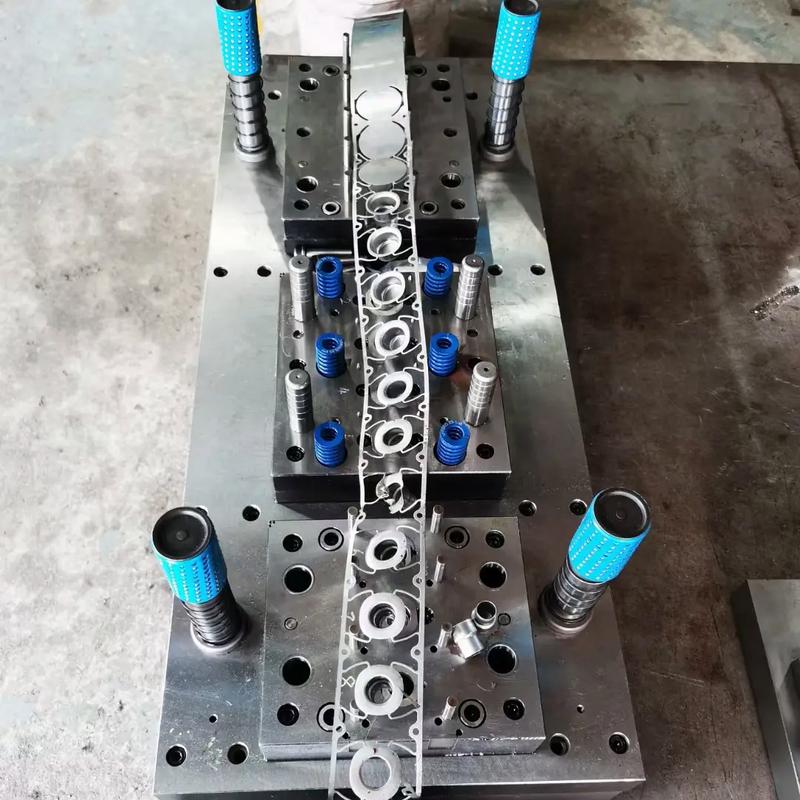

2. Precision of processing equipment: In processes such as stamping, bending, and shearing, if the equipment accuracy is insufficient or the mold gap is not reasonable, it will lead to uneven deformation of the material, which in turn affects the flatness.

3. Processing technology parameters: Such as stamping speed, mold gap, bending radius, springback control, etc., will affect the deformation of the sheet material.

4. Environmental factors: Changes in temperature and humidity may cause slight deformation of the material; improper operations during handling and stacking may also cause warping of the sheet material.

Second, Flatness Control Measures

1. Select high-quality cold-rolled steel raw materials

Preferably select cold-rolled steel plates with smooth surfaces, small thickness tolerances, and stable mechanical properties. For parts with high precision requirements, annealed cold-rolled plates that have been flattened can be selected.

2. Optimize mold design and equipment adjustment

The design of molds should fully consider the fluidity and springback characteristics of the material, and reasonably set the mold gap and corner radius. Regularly calibrate equipment to ensure that the accuracy of stamping and bending equipment is in good condition.

3. Adopt flattening technology

For workpieces with slight deformation after processing, flattening treatment can be carried out through flatting machines, rolling machines, or hydraulic flattening equipment to effectively restore the flatness of the sheet material.

4. Reasonable arrangement of processing sequence

When processing in multiple processes, it should be carried out in the order of large size and large area forming first, and then local detail processing to avoid overall deformation caused by local stress concentration.

5. Control processing stress

During processes such as stamping and bending, residual stresses will be generated internally in the material, which may cause deformation during subsequent use. Residual stresses can be eliminated by annealing treatment or local heating to improve the stability of flatness.

6. Strengthen process quality control

Establish a comprehensive quality inspection system, use laser flatness gauges, coordinate measuring machines, and other equipment to monitor the flatness of parts in real time, and promptly detect and correct deviations.

Three, Case Analysis and Application

Taking a car parts manufacturing enterprise as an example, it once encountered a batch of flatness problems in the production of cold-rolled sheet metal shells. Analysis showed that the main problem was due to uneven mold gaps and unreasonable stamping pressure settings. After redesigning the mold gaps, optimizing the forming parameters, and introducing flattening processes, the qualified rate of product flatness was improved from 78% to over 98%, significantly improving product quality and customer satisfaction.

Four, Conclusion

The flatness control of cold-rolled sheet metal parts is a systematic project, which requires collaborative efforts from multiple links such as raw material selection, mold design, process optimization, and quality inspection. Only by strictly controlling each link can the final product's flatness meet the design requirements and satisfy the dual needs of high precision assembly and aesthetics. With the development of intelligent manufacturing technology, the precision and efficiency of flatness control can be further improved by introducing automated detection and AI process optimization systems in the future.

Cold rolled steel plates are widely used in the fields of automotive manufacturing, home appliances, electronic equipment, and precision instruments due to their smooth surface, even thickness, and excellent mechanical properties. During the sheet metal processing process, the flatness of the plates directly affects the appearance quality, assembly accuracy, and performance of the final product. Therefore, how to effectively control the flatness of cold rolled steel plates during sheet metal processing is a very critical technical issue.

First, Influencing factors of flatness

1. Raw material quality: Cold-rolled steel plates themselves may have minor waves, curvature, or sickle bend, etc., which will be magnified in subsequent processing, affecting the flatness of the finished product.

2. Precision of processing equipment: In processes such as stamping, bending, and shearing, if the equipment accuracy is insufficient or the mold gap is not reasonable, it will lead to uneven deformation of the material, which in turn affects the flatness.

3. Processing technology parameters: Such as stamping speed, mold gap, bending radius, springback control, etc., will affect the deformation of the sheet material.

4. Environmental factors: Changes in temperature and humidity may cause slight deformation of the material; improper operations during handling and stacking may also cause warping of the sheet material.

Second, Flatness Control Measures

1. Select high-quality cold-rolled steel raw materials

Preferably select cold-rolled steel plates with smooth surfaces, small thickness tolerances, and stable mechanical properties. For parts with high precision requirements, annealed cold-rolled plates that have been flattened can be selected.

2. Optimize mold design and equipment adjustment

The design of molds should fully consider the fluidity and springback characteristics of the material, and reasonably set the mold gap and corner radius. Regularly calibrate equipment to ensure that the accuracy of stamping and bending equipment is in good condition.

3. Adopt flattening technology

For workpieces with slight deformation after processing, flattening treatment can be carried out through flatting machines, rolling machines, or hydraulic flattening equipment to effectively restore the flatness of the sheet material.

4. Reasonable arrangement of processing sequence

When processing in multiple processes, it should be carried out in the order of large size and large area forming first, and then local detail processing to avoid overall deformation caused by local stress concentration.

5. Control processing stress

During processes such as stamping and bending, residual stresses will be generated internally in the material, which may cause deformation during subsequent use. Residual stresses can be eliminated by annealing treatment or local heating to improve the stability of flatness.

6. Strengthen process quality control

Establish a comprehensive quality inspection system, use laser flatness gauges, coordinate measuring machines, and other equipment to monitor the flatness of parts in real time, and promptly detect and correct deviations.

Three, Case Analysis and Application

Taking a car parts manufacturing enterprise as an example, it once encountered a batch of flatness problems in the production of cold-rolled sheet metal shells. Analysis showed that the main problem was due to uneven mold gaps and unreasonable stamping pressure settings. After redesigning the mold gaps, optimizing the forming parameters, and introducing flattening processes, the qualified rate of product flatness was improved from 78% to over 98%, significantly improving product quality and customer satisfaction.

Four, Conclusion

The flatness control of cold-rolled sheet metal parts is a systematic project, which requires collaborative efforts from multiple links such as raw material selection, mold design, process optimization, and quality inspection. Only by strictly controlling each link can the final product's flatness meet the design requirements and satisfy the dual needs of high precision assembly and aesthetics. With the development of intelligent manufacturing technology, the precision and efficiency of flatness control can be further improved by introducing automated detection and AI process optimization systems in the future.