News

How to control the dimensional accuracy in mold manufacturing

Category:answer Publishing time:2025-12-20 22:26:32 Browse: Times

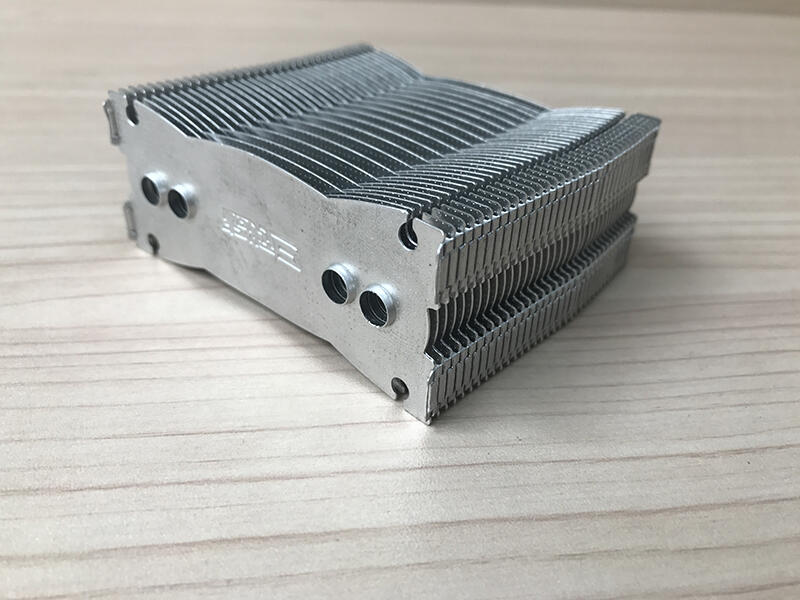

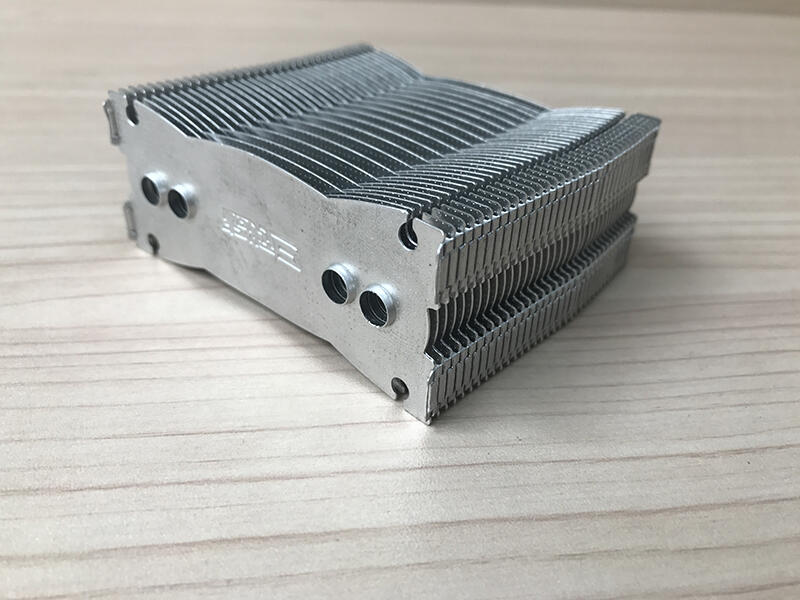

In modern industrial production, molds act as important basic process equipment and are widely used in various fields such as automobiles, electronics, aerospace, household appliances, and more. The dimensional accuracy of molds directly affects the quality and performance of the final product, therefore, how to effectively control the dimensional accuracy during the mold manufacturing process has become one of the key issues in mold design and manufacturing.

1. Precision Control in the Mold Design Stage

The design of the mold is the foundation for determining its accuracy. In the design stage, engineers need to reasonably determine the size and tolerance range of the mold cavity based on the structure, material characteristics, and forming process of the product. Typically, the mold cavity size needs to be reverse compensated based on the product size, taking into account the effects of material shrinkage and thermal expansion. In addition, the use of advanced 3D modeling software (such as UG, SolidWorks, etc.) for virtual simulation can help to discover potential design defects in advance, thereby optimizing the structural design and improving processing accuracy.

2. Material Selection and Pretreatment

The selection of mold material directly affects its wear resistance, hardness, and size stability. Common mold steels such as Cr12MoV, SKD11, H13, etc., have good heat treatment performance and mechanical properties. To reduce heat treatment deformation, the material should be subjected to sufficient preheating treatment before processing, such as spheroidizing annealing or quenching and tempering treatment, to eliminate internal stress and improve the machinability of the material.

3. Precision Assurance in the Processing Process

The processing technology in mold manufacturing mainly includes turning, milling, electrospark machining (EDM), wire cutting, and grinding. Each process requires strict control of processing parameters and the use of high-precision equipment such as CNC machines and coordinate grinding machines to ensure size accuracy. At the same time, operators should calibrate measuring tools such as micrometers, calipers, and projectors regularly to ensure the accuracy of measurement data.

In complex cavity processing, high-speed machining technology (HSM) and multi-axis CNC machining can be used to improve surface quality and dimensional consistency. For the electro-processing link, appropriate electrode materials and discharge parameters should be selected to avoid dimensional deviation due to uneven discharge.

4. Impact of Heat Treatment on Size Accuracy

Heat treatment is a key link in mold manufacturing, directly affecting the hardness and size stability of the mold. A reasonable heat treatment process should include steps such as pre-cooling, quenching, and tempering. To reduce heat treatment deformation, vacuum heat treatment or controlled atmosphere furnace treatment is often used, and deep cooling treatment can further stabilize the material structure and improve the retention of size accuracy.

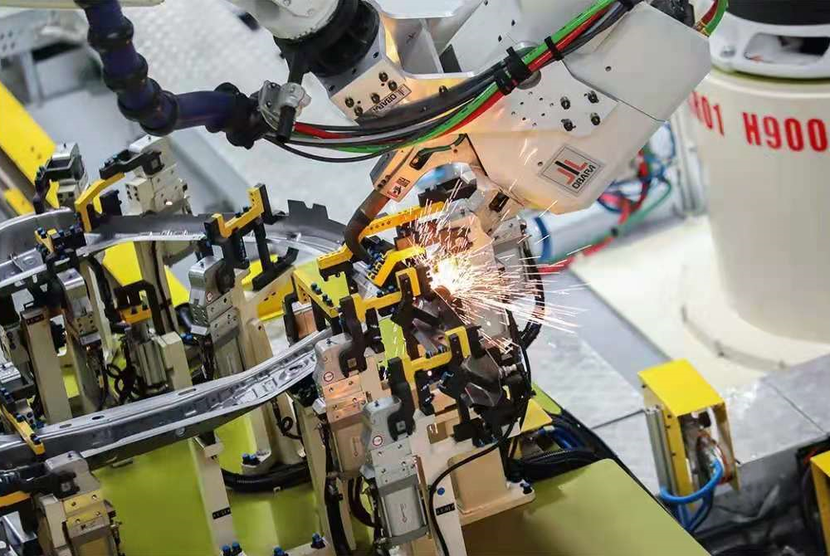

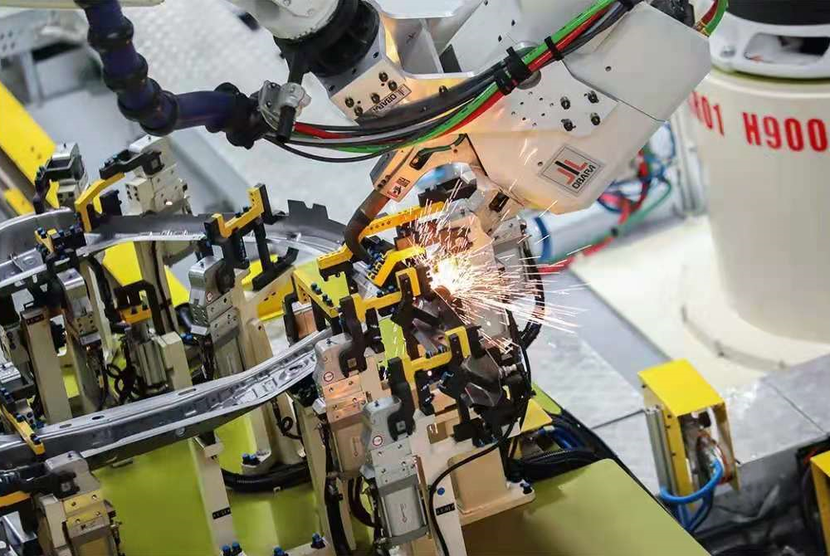

5. Adjustments in Assembly and Trial Molding Stages

During the mold assembly process, the clearance between the various components should be strictly controlled within the design tolerance range. After assembly, the forming performance and size accuracy of the mold should be inspected through trial molding. The trial molding parts should be subject to comprehensive testing, and if there are deviations, the cavity or parting surface dimensions should be adjusted in time, and polishing or welding repair may be necessary if required.

Conclusion

In summary, the control of size accuracy in mold manufacturing is a systematic project, involving multiple links such as design, material, processing, heat treatment, and detection. Only by strictly implementing process specifications at each stage and combining modern manufacturing technology and management methods, can the mold meet the high precision requirements, thus improving product quality and market competitiveness. With the development of intelligent manufacturing and digital manufacturing, the future mold manufacturing will be more efficient, accurate, and automated.

In modern industrial production, molds act as important basic process equipment and are widely used in various fields such as automobiles, electronics, aerospace, household appliances, and more. The dimensional accuracy of molds directly affects the quality and performance of the final product, therefore, how to effectively control the dimensional accuracy during the mold manufacturing process has become one of the key issues in mold design and manufacturing.

1. Precision Control in the Mold Design Stage

The design of the mold is the foundation for determining its accuracy. In the design stage, engineers need to reasonably determine the size and tolerance range of the mold cavity based on the structure, material characteristics, and forming process of the product. Typically, the mold cavity size needs to be reverse compensated based on the product size, taking into account the effects of material shrinkage and thermal expansion. In addition, the use of advanced 3D modeling software (such as UG, SolidWorks, etc.) for virtual simulation can help to discover potential design defects in advance, thereby optimizing the structural design and improving processing accuracy.

2. Material Selection and Pretreatment

The selection of mold material directly affects its wear resistance, hardness, and size stability. Common mold steels such as Cr12MoV, SKD11, H13, etc., have good heat treatment performance and mechanical properties. To reduce heat treatment deformation, the material should be subjected to sufficient preheating treatment before processing, such as spheroidizing annealing or quenching and tempering treatment, to eliminate internal stress and improve the machinability of the material.

3. Precision Assurance in the Processing Process

The processing technology in mold manufacturing mainly includes turning, milling, electrospark machining (EDM), wire cutting, and grinding. Each process requires strict control of processing parameters and the use of high-precision equipment such as CNC machines and coordinate grinding machines to ensure size accuracy. At the same time, operators should calibrate measuring tools such as micrometers, calipers, and projectors regularly to ensure the accuracy of measurement data.

In complex cavity processing, high-speed machining technology (HSM) and multi-axis CNC machining can be used to improve surface quality and dimensional consistency. For the electro-processing link, appropriate electrode materials and discharge parameters should be selected to avoid dimensional deviation due to uneven discharge.

4. Impact of Heat Treatment on Size Accuracy

Heat treatment is a key link in mold manufacturing, directly affecting the hardness and size stability of the mold. A reasonable heat treatment process should include steps such as pre-cooling, quenching, and tempering. To reduce heat treatment deformation, vacuum heat treatment or controlled atmosphere furnace treatment is often used, and deep cooling treatment can further stabilize the material structure and improve the retention of size accuracy.

5. Adjustments in Assembly and Trial Molding Stages

During the mold assembly process, the clearance between the various components should be strictly controlled within the design tolerance range. After assembly, the forming performance and size accuracy of the mold should be inspected through trial molding. The trial molding parts should be subject to comprehensive testing, and if there are deviations, the cavity or parting surface dimensions should be adjusted in time, and polishing or welding repair may be necessary if required.

Conclusion

In summary, the control of size accuracy in mold manufacturing is a systematic project, involving multiple links such as design, material, processing, heat treatment, and detection. Only by strictly implementing process specifications at each stage and combining modern manufacturing technology and management methods, can the mold meet the high precision requirements, thus improving product quality and market competitiveness. With the development of intelligent manufacturing and digital manufacturing, the future mold manufacturing will be more efficient, accurate, and automated.