News

How to control deformation in sheet metal hydroforming

Category:answer Publishing time:2025-12-13 07:18:32 Browse: Times

One, the Basic Principles of Sheet Metal Hydroforming

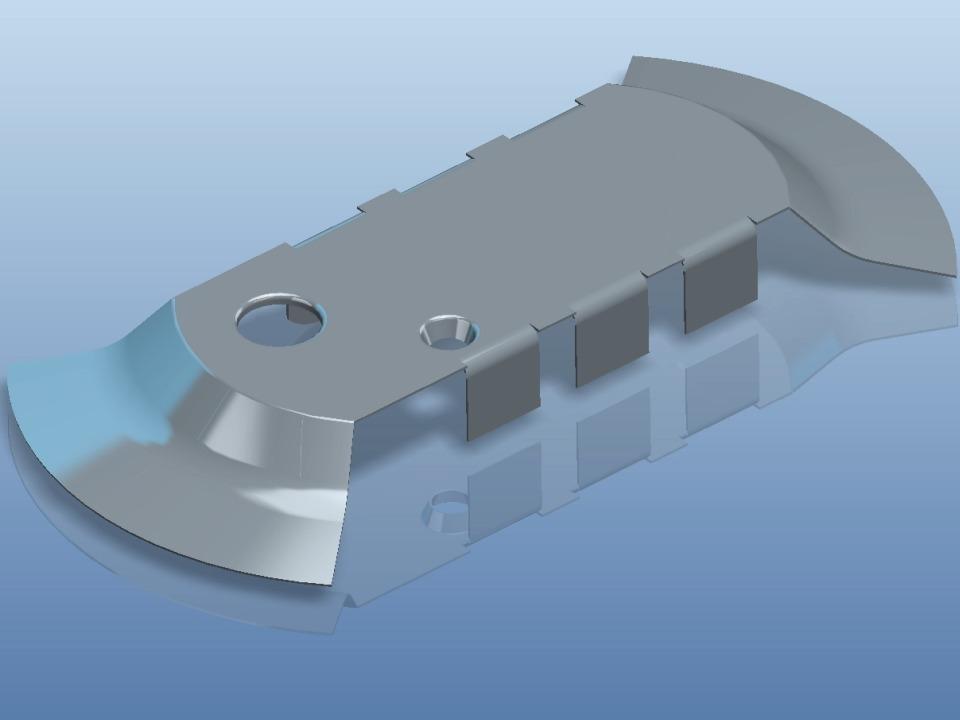

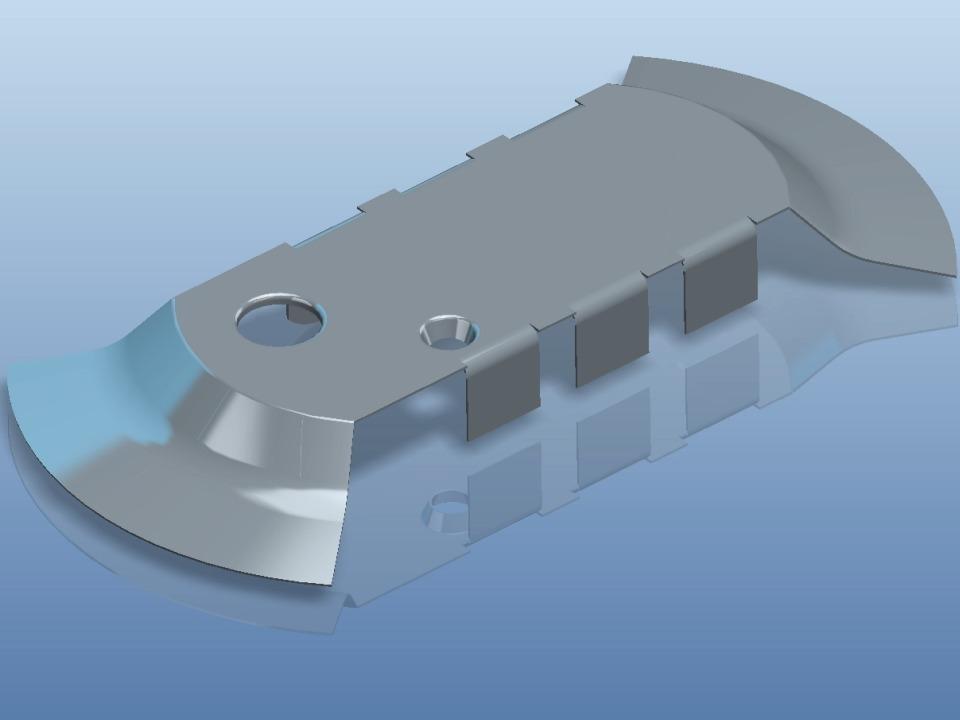

Sheet metal hydroforming is a processing method that uses liquid pressure as a transmission medium to drive the plastic deformation of metal sheets. Common forms include hydraulic deep drawing, hydraulic bulging, and hydraulic flanging. In the forming process, the uniform action of liquid pressure on the surface of the sheet makes the material flow and deform in the mold, thereby obtaining the required shape of the workpiece.

Two, the Main Reasons for Deformation

In the sheet metal hydroforming process, deformation mainly comes from the following aspects:

1. Differences in material characteristics: Different metal sheet materials have differences in plastic deformation capacity and anisotropy, leading to uneven local deformation.

2. Unreasonable mold design: If the mold cavity design is not proper or the blank holder fitting is not good, it is easy to cause local stress concentration, leading to wrinkling or cracking.

3. Improper hydraulic parameter settings: Excessive pressure or rapid loading rate may cause excessive stretching or local failure of the material; on the contrary, insufficient pressure cannot achieve full forming.

4. Poor lubrication conditions: Uneven friction will change the flow path of the material, thereby affecting the forming quality.

Three, Key Measures for Deformation Control

To effectively control the deformation behavior in the sheet metal hydroforming process, the following aspects can be started from:

1. Optimization of mold design

Use finite element simulation technology to optimize the analysis of the mold cavity and the blank holder structure, design the gap between the blank holder and the die reasonably to reduce the unevenness of material flow, and avoid wrinkling and cracking.

2. Precise control of hydraulic parameters

According to the specific material characteristics, set the hydraulic loading curve reasonably. For example, use lower pressure in the early stage of forming to promote material flow, and gradually increase the pressure in the later stage of forming to ensure forming accuracy.

3. Selecting appropriate lubrication methods

Use high-performance lubricants or coating technology to reduce the friction coefficient between the mold and the sheet material, making material flow more uniform and reducing local stress concentration.

4. Application of advanced forming technology

Combine advanced technologies such as internal high-pressure forming and multi-directional hydraulic forming to enhance the forming capability of complex parts while effectively controlling the degree of deformation.

5. Strengthen process monitoring and feedbac

Introduce an on-line detection system to monitor the pressure and displacement parameters in the forming process in real time, and adjust the process parameters in time based on data feedback to ensure the stability of the forming quality.

Four, Conclusion

In summary, deformation control in sheet metal hydroforming is a systematic project, which requires comprehensive optimization from aspects such as material properties, mold design, process parameters, and lubrication conditions. With the development of computer simulation technology and intelligent manufacturing, the automation and intelligence level of sheet metal hydroforming is continuously improving, providing a strong guarantee for high-quality and high-precision forming. In the future, with the continuous emergence of new materials and new processes, this technology will play an important role in a wider range of fields.

One, the Basic Principles of Sheet Metal Hydroforming

Sheet metal hydroforming is a processing method that uses liquid pressure as a transmission medium to drive the plastic deformation of metal sheets. Common forms include hydraulic deep drawing, hydraulic bulging, and hydraulic flanging. In the forming process, the uniform action of liquid pressure on the surface of the sheet makes the material flow and deform in the mold, thereby obtaining the required shape of the workpiece.

Two, the Main Reasons for Deformation

In the sheet metal hydroforming process, deformation mainly comes from the following aspects:

1. Differences in material characteristics: Different metal sheet materials have differences in plastic deformation capacity and anisotropy, leading to uneven local deformation.

2. Unreasonable mold design: If the mold cavity design is not proper or the blank holder fitting is not good, it is easy to cause local stress concentration, leading to wrinkling or cracking.

3. Improper hydraulic parameter settings: Excessive pressure or rapid loading rate may cause excessive stretching or local failure of the material; on the contrary, insufficient pressure cannot achieve full forming.

4. Poor lubrication conditions: Uneven friction will change the flow path of the material, thereby affecting the forming quality.

Three, Key Measures for Deformation Control

To effectively control the deformation behavior in the sheet metal hydroforming process, the following aspects can be started from:

1. Optimization of mold design

Use finite element simulation technology to optimize the analysis of the mold cavity and the blank holder structure, design the gap between the blank holder and the die reasonably to reduce the unevenness of material flow, and avoid wrinkling and cracking.

2. Precise control of hydraulic parameters

According to the specific material characteristics, set the hydraulic loading curve reasonably. For example, use lower pressure in the early stage of forming to promote material flow, and gradually increase the pressure in the later stage of forming to ensure forming accuracy.

3. Selecting appropriate lubrication methods

Use high-performance lubricants or coating technology to reduce the friction coefficient between the mold and the sheet material, making material flow more uniform and reducing local stress concentration.

4. Application of advanced forming technology

Combine advanced technologies such as internal high-pressure forming and multi-directional hydraulic forming to enhance the forming capability of complex parts while effectively controlling the degree of deformation.

5. Strengthen process monitoring and feedbac

Introduce an on-line detection system to monitor the pressure and displacement parameters in the forming process in real time, and adjust the process parameters in time based on data feedback to ensure the stability of the forming quality.

Four, Conclusion

In summary, deformation control in sheet metal hydroforming is a systematic project, which requires comprehensive optimization from aspects such as material properties, mold design, process parameters, and lubrication conditions. With the development of computer simulation technology and intelligent manufacturing, the automation and intelligence level of sheet metal hydroforming is continuously improving, providing a strong guarantee for high-quality and high-precision forming. In the future, with the continuous emergence of new materials and new processes, this technology will play an important role in a wider range of fields.