News

How to choose the layer thickness in metal 3D printing

Category:answer Publishing time:2025-09-21 05:58:34 Browse: Times

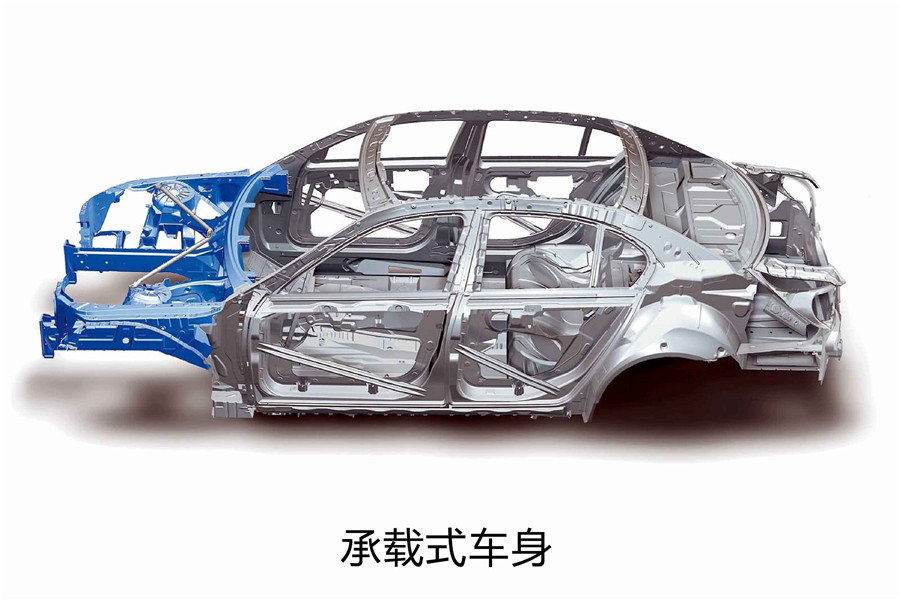

With the continuous development of additive manufacturing technology, metal 3D printing has been widely used in high-end manufacturing fields such as aerospace, medical, and automotive. Among them, layer thickness, as one of the important parameters affecting printing quality and efficiency, needs to be carefully weighed and selected in actual operation. This article will discuss how to reasonably select layer thickness in metal 3D printing from multiple perspectives.

One, Definition and Function of Layer Thickness

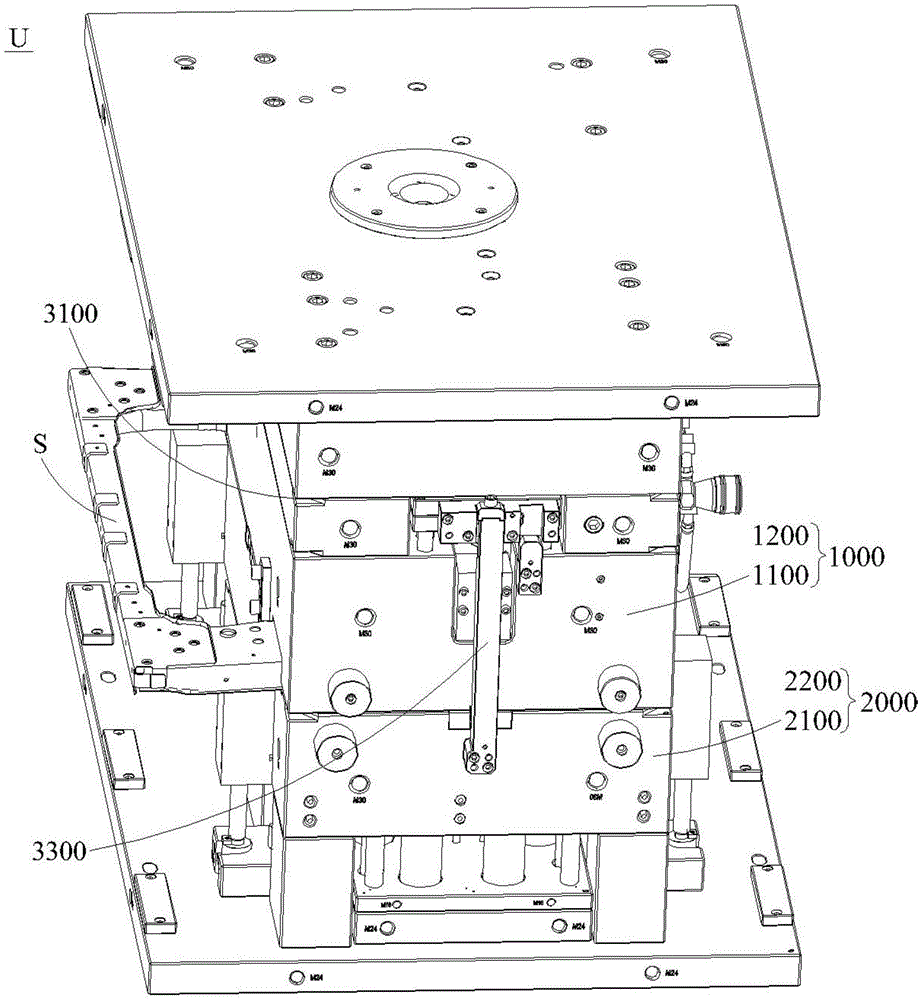

In the metal 3D printing process, layer thickness (Layer Thickness) refers to the thickness of the material accumulation formed after each layer of powder material is melted by a laser or electron beam. It is usually measured in micrometers (μm). Layer thickness not only directly affects the surface roughness and detail accuracy of the printed part but also relates to printing speed, equipment wear, and manufacturing cost.

Two, The Impact of Layer Thickness on Printing Quality

1. Surface Quality and Precision

A thinner layer thickness means that each layer of material is thinner, which can achieve finer geometric structures and reduce the 'stair-stepping effect', thereby obtaining a smoother surface quality. For applications requiring high dimensional accuracy and good surface finish, such as precision medical devices or complex molds, a layer thickness of 20~30 μm is usually recommended.

2. Mechanical Properties

A thicker layer thickness can lead to loose interlayer bonding, which may affect the density and mechanical properties of the part. On the other hand, a thinner layer thickness helps to improve the density of the material, enhance interlayer bonding strength, and thus increase the overall strength and durability of the part.

Three, The Impact of Layer Thickness on Printing Efficiency and Cost

1. Molding Speed

A thicker layer thickness results in fewer print layers, leading to a shorter overall printing time. For large parts or mass production, appropriately increasing the layer thickness can significantly improve production efficiency.

2. Equipment Wear and Cost

Although a smaller layer thickness can improve quality, it will increase the number of scans and equipment running time, leading to faster wear of components such as the laser head and powder spreading system, and indirectly increasing maintenance costs. Therefore, in actual production, the balance between quality and efficiency should be weighed according to the part requirements.

Four, Recommended Layer Thicknesses for Different Application Scenarios

- For high-precision parts (such as dental implants, microstructures): it is recommended to use a layer thickness of 20~30 μm to achieve the best surface quality and detail reproduction.

- For structural or functional parts (such as engine components): a general choice of about 50 μm is made, balancing strength and efficiency.

- For large industrial parts or prototype verification: layer thicknesses of 80~100 μm or even higher can be used to accelerate printing speed and reduce costs.

Five, Conclusion

Selecting the appropriate layer thickness is a key technical decision in the metal 3D printing process. It not only affects the final performance and appearance of the part but is also closely related to production efficiency and manufacturing cost. In practical applications, engineers should evaluate and optimize the layer thickness settings comprehensively, considering factors such as part structure, usage scenario, and equipment performance, in order to find the best balance between quality and efficiency. With the continuous advancement of technology, the layer thickness control of metal 3D printing in the future will be more refined, bringing greater flexibility and innovative space to the manufacturing industry.

With the continuous development of additive manufacturing technology, metal 3D printing has been widely used in high-end manufacturing fields such as aerospace, medical, and automotive. Among them, layer thickness, as one of the important parameters affecting printing quality and efficiency, needs to be carefully weighed and selected in actual operation. This article will discuss how to reasonably select layer thickness in metal 3D printing from multiple perspectives.

One, Definition and Function of Layer Thickness

In the metal 3D printing process, layer thickness (Layer Thickness) refers to the thickness of the material accumulation formed after each layer of powder material is melted by a laser or electron beam. It is usually measured in micrometers (μm). Layer thickness not only directly affects the surface roughness and detail accuracy of the printed part but also relates to printing speed, equipment wear, and manufacturing cost.

Two, The Impact of Layer Thickness on Printing Quality

1. Surface Quality and Precision

A thinner layer thickness means that each layer of material is thinner, which can achieve finer geometric structures and reduce the 'stair-stepping effect', thereby obtaining a smoother surface quality. For applications requiring high dimensional accuracy and good surface finish, such as precision medical devices or complex molds, a layer thickness of 20~30 μm is usually recommended.

2. Mechanical Properties

A thicker layer thickness can lead to loose interlayer bonding, which may affect the density and mechanical properties of the part. On the other hand, a thinner layer thickness helps to improve the density of the material, enhance interlayer bonding strength, and thus increase the overall strength and durability of the part.

Three, The Impact of Layer Thickness on Printing Efficiency and Cost

1. Molding Speed

A thicker layer thickness results in fewer print layers, leading to a shorter overall printing time. For large parts or mass production, appropriately increasing the layer thickness can significantly improve production efficiency.

2. Equipment Wear and Cost

Although a smaller layer thickness can improve quality, it will increase the number of scans and equipment running time, leading to faster wear of components such as the laser head and powder spreading system, and indirectly increasing maintenance costs. Therefore, in actual production, the balance between quality and efficiency should be weighed according to the part requirements.

Four, Recommended Layer Thicknesses for Different Application Scenarios

- For high-precision parts (such as dental implants, microstructures): it is recommended to use a layer thickness of 20~30 μm to achieve the best surface quality and detail reproduction.

- For structural or functional parts (such as engine components): a general choice of about 50 μm is made, balancing strength and efficiency.

- For large industrial parts or prototype verification: layer thicknesses of 80~100 μm or even higher can be used to accelerate printing speed and reduce costs.

Five, Conclusion

Selecting the appropriate layer thickness is a key technical decision in the metal 3D printing process. It not only affects the final performance and appearance of the part but is also closely related to production efficiency and manufacturing cost. In practical applications, engineers should evaluate and optimize the layer thickness settings comprehensively, considering factors such as part structure, usage scenario, and equipment performance, in order to find the best balance between quality and efficiency. With the continuous advancement of technology, the layer thickness control of metal 3D printing in the future will be more refined, bringing greater flexibility and innovative space to the manufacturing industry.