News

How to Choose Food-grade Stainless Steel Sheet Metal

Category:answer Publishing time:2025-11-14 00:55:48 Browse: Times

In modern industrial production, especially in industries such as food processing, pharmaceuticals, beverages, and dairy products, the hygiene and safety requirements for equipment and materials are extremely strict. Among them, food-grade stainless steel sheet metal, as one of the important raw materials for manufacturing food processing equipment, its selection and quality directly affect the safety of the product and the service life of the equipment. Therefore, correctly selecting food-grade stainless steel sheet metal is a key link in ensuring production safety and improving equipment performance.

1. Understanding the Classification of Food-grade Stainless Steel

Food-grade stainless steel mainly refers to stainless steel materials that meet national or international food safety standards, commonly including grades 304 (06Cr19Ni10) and 316 (06Cr17Ni12Mo2) austenitic stainless steel. These two types of stainless steel have good corrosion resistance, high-temperature resistance, and non-toxic and odorless properties, making them suitable for the manufacturing of equipment that comes into direct contact with food.

- 304 stainless steel: is the most commonly used material in the food industry, with good corrosion resistance and mechanical properties, suitable for food processing under normal or medium temperature conditions.

- 316 stainless steel: contains molybdenum, which has stronger resistance to chloride ion corrosion and is more suitable for high salt content, high corrosive environments, such as seafood processing, dairy products, and acidic liquid treatment fields.

Two, selection standards and certifications

When choosing food-grade stainless steel sheet metal, it is necessary to pay attention to whether it has passed relevant food safety certifications, such as China's GB 4806 series food contact material standards, the EU's EC No 1935/2004 regulations, and the US FDA (Food and Drug Administration) standards. These standards have clear provisions on the heavy metal migration amount, surface roughness, corrosion resistance, and other aspects of the material.

In addition, during the procurement process, it is necessary to require suppliers to provide material certificates (such as quality assurance certificates, material analysis reports) and relevant inspection reports to ensure the authenticity and compliance of the material.

Three, consider processing technology and usage environment

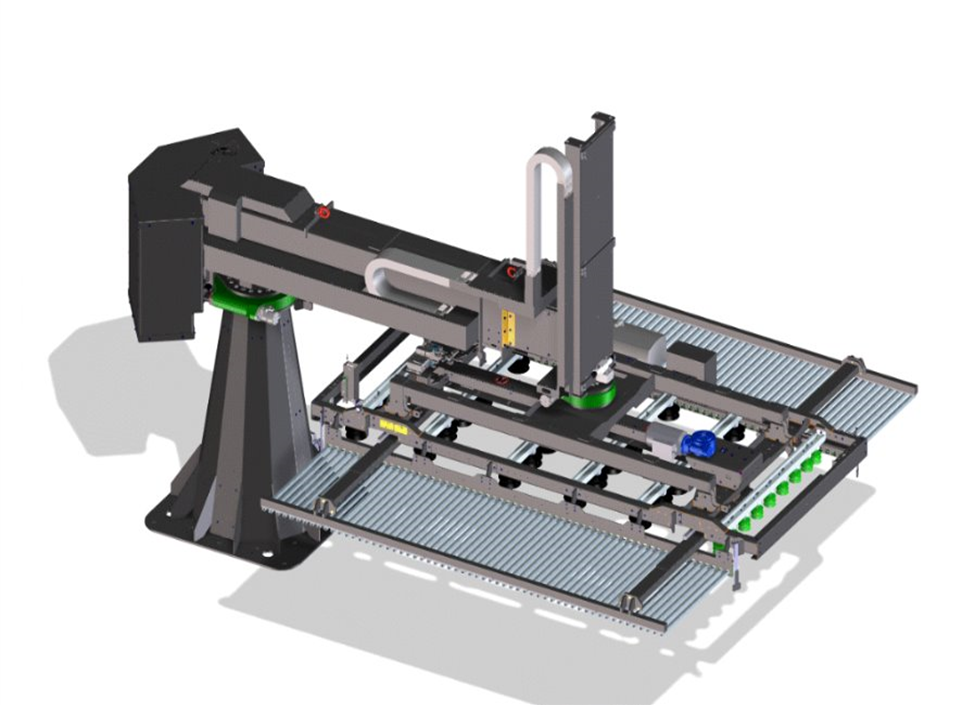

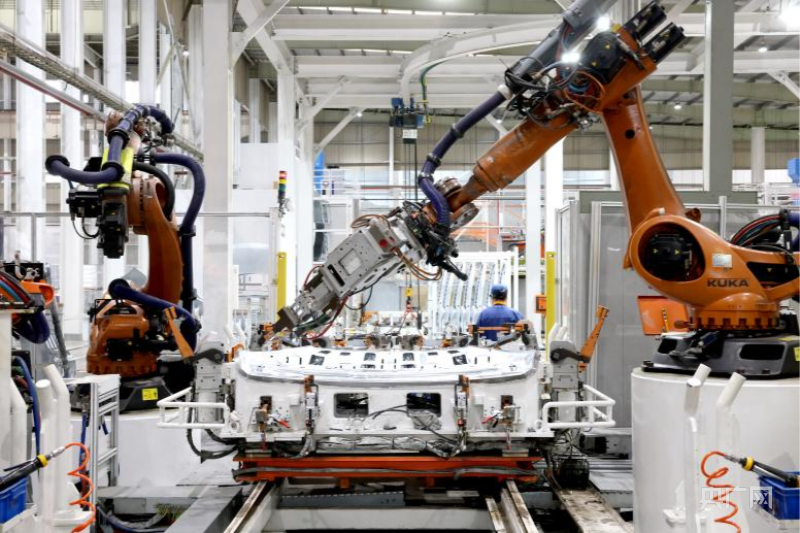

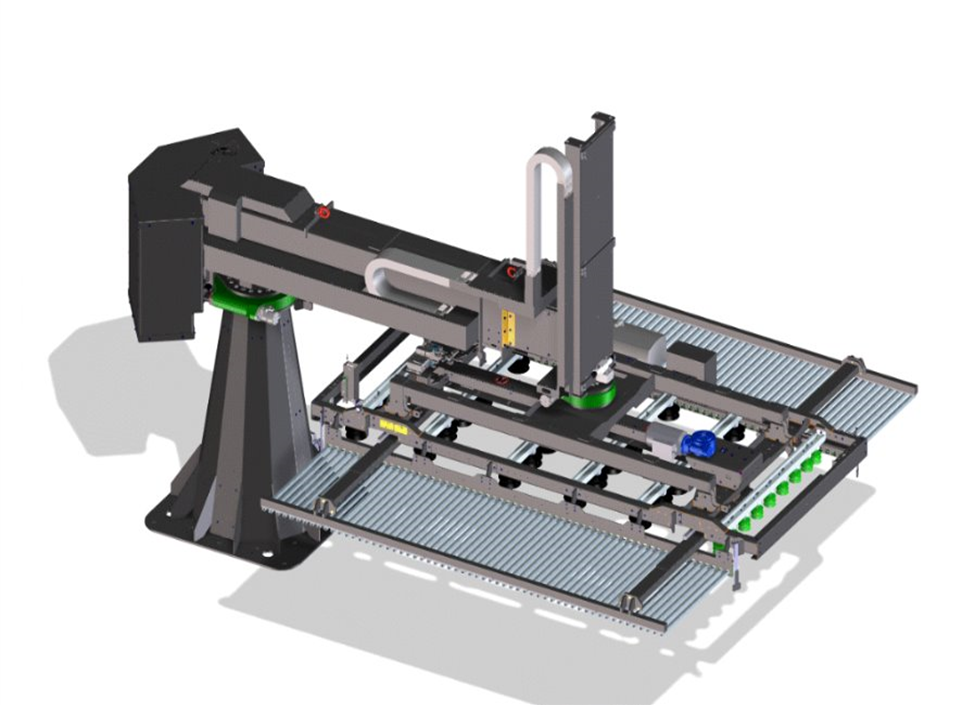

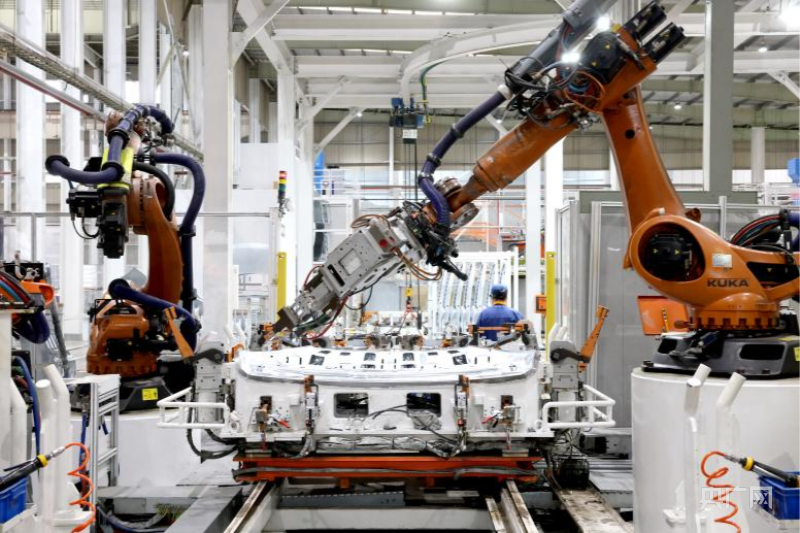

Food equipment often needs to go through stamping, welding, bending and other sheet metal processing processes, so when choosing stainless steel materials, it is necessary to consider their processability. Generally, austenitic stainless steel has good plasticity and welding properties, which is suitable for complex processing processes.

At the same time, the usage environment also determines the selection of stainless steel. For example:

- High temperature environment: it is necessary to choose materials with good thermal stability;

- High humidity and high salt environment: give priority to the use of 316 stainless steel;

- In the case of contact with strong acid and alkali: consider using higher-grade special stainless steel or carry out surface passivation treatment.

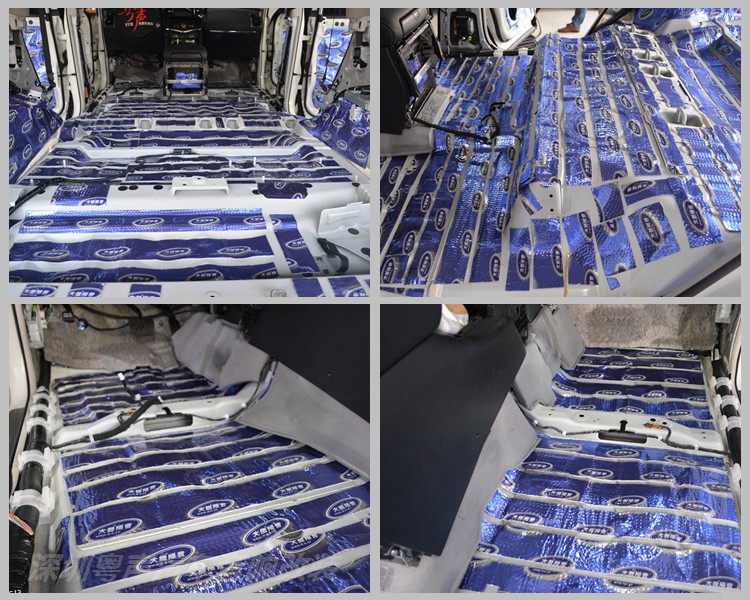

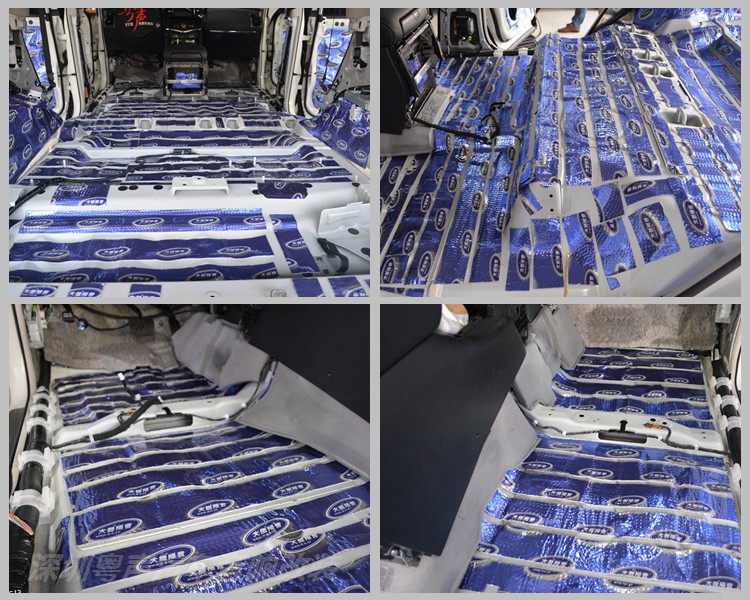

Four, pay attention to surface treatment and cleaning performance

The food contact surface must be easy to clean, not easy to leave food residue, and prevent the growth of bacteria. Therefore, the surface treatment of stainless steel sheet metal is also very important. Common surface treatment methods include:

- Mirror polishing (No.8): suitable for areas with extremely high cleanliness requirements;

- Wire drawing treatment (No.4): beautiful and has certain scratch resistance;

- Electrolytic polishing: can improve the corrosion resistance and cleaning performance of the material.

The surface roughness should generally be controlled within Ra ≤ 0.8 μm to meet the hygiene requirements of the food industry.

Conclusion

In the food processing industry, the selection of appropriate food-grade stainless steel sheet metal is not only related to the safety and quality of the product, but also affects the service life and maintenance cost of the equipment. Enterprises should comprehensively consider factors such as the chemical properties, mechanical properties, processing technology, usage environment, and surface treatment of the material during the procurement process, and choose to cooperate with qualified regular suppliers to ensure the compliance and safety of the production process. Only in this way can the efficient and safe operation of food equipment truly be realized.

In modern industrial production, especially in industries such as food processing, pharmaceuticals, beverages, and dairy products, the hygiene and safety requirements for equipment and materials are extremely strict. Among them, food-grade stainless steel sheet metal, as one of the important raw materials for manufacturing food processing equipment, its selection and quality directly affect the safety of the product and the service life of the equipment. Therefore, correctly selecting food-grade stainless steel sheet metal is a key link in ensuring production safety and improving equipment performance.

1. Understanding the Classification of Food-grade Stainless Steel

Food-grade stainless steel mainly refers to stainless steel materials that meet national or international food safety standards, commonly including grades 304 (06Cr19Ni10) and 316 (06Cr17Ni12Mo2) austenitic stainless steel. These two types of stainless steel have good corrosion resistance, high-temperature resistance, and non-toxic and odorless properties, making them suitable for the manufacturing of equipment that comes into direct contact with food.

- 304 stainless steel: is the most commonly used material in the food industry, with good corrosion resistance and mechanical properties, suitable for food processing under normal or medium temperature conditions.

- 316 stainless steel: contains molybdenum, which has stronger resistance to chloride ion corrosion and is more suitable for high salt content, high corrosive environments, such as seafood processing, dairy products, and acidic liquid treatment fields.

Two, selection standards and certifications

When choosing food-grade stainless steel sheet metal, it is necessary to pay attention to whether it has passed relevant food safety certifications, such as China's GB 4806 series food contact material standards, the EU's EC No 1935/2004 regulations, and the US FDA (Food and Drug Administration) standards. These standards have clear provisions on the heavy metal migration amount, surface roughness, corrosion resistance, and other aspects of the material.

In addition, during the procurement process, it is necessary to require suppliers to provide material certificates (such as quality assurance certificates, material analysis reports) and relevant inspection reports to ensure the authenticity and compliance of the material.

Three, consider processing technology and usage environment

Food equipment often needs to go through stamping, welding, bending and other sheet metal processing processes, so when choosing stainless steel materials, it is necessary to consider their processability. Generally, austenitic stainless steel has good plasticity and welding properties, which is suitable for complex processing processes.

At the same time, the usage environment also determines the selection of stainless steel. For example:

- High temperature environment: it is necessary to choose materials with good thermal stability;

- High humidity and high salt environment: give priority to the use of 316 stainless steel;

- In the case of contact with strong acid and alkali: consider using higher-grade special stainless steel or carry out surface passivation treatment.

Four, pay attention to surface treatment and cleaning performance

The food contact surface must be easy to clean, not easy to leave food residue, and prevent the growth of bacteria. Therefore, the surface treatment of stainless steel sheet metal is also very important. Common surface treatment methods include:

- Mirror polishing (No.8): suitable for areas with extremely high cleanliness requirements;

- Wire drawing treatment (No.4): beautiful and has certain scratch resistance;

- Electrolytic polishing: can improve the corrosion resistance and cleaning performance of the material.

The surface roughness should generally be controlled within Ra ≤ 0.8 μm to meet the hygiene requirements of the food industry.

Conclusion

In the food processing industry, the selection of appropriate food-grade stainless steel sheet metal is not only related to the safety and quality of the product, but also affects the service life and maintenance cost of the equipment. Enterprises should comprehensively consider factors such as the chemical properties, mechanical properties, processing technology, usage environment, and surface treatment of the material during the procurement process, and choose to cooperate with qualified regular suppliers to ensure the compliance and safety of the production process. Only in this way can the efficient and safe operation of food equipment truly be realized.