News

How to choose a supplier for sheet metal manufacturing

Category:answer Publishing time:2025-11-10 17:20:41 Browse: Times

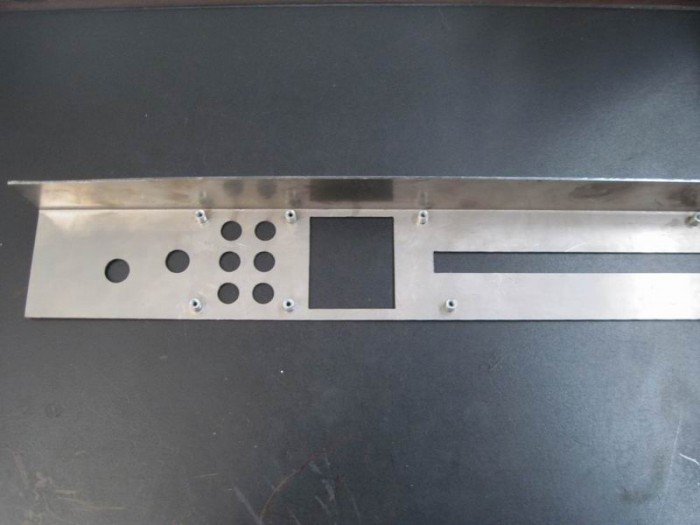

Firstly, investigating the technical strength and production capacity of the supplier is a key step in choosing a sheet metal manufacturing service provider. Enterprises should understand whether the supplier has advanced equipment such as CNC punch presses, laser cutting machines, and bending machines, as well as the degree of automation and processing accuracy of their equipment. In addition, they also need to pay attention to the professional capabilities of their technical team, whether they have the ability to provide one-stop services from design to finished product manufacturing, and whether they can handle the processing requirements of complex structural components.

Secondly, the quality management system is an important standard for measuring the reliability of suppliers. Excellent sheet metal manufacturing suppliers usually have a sound quality control system, such as passing international quality management system certifications such as ISO 9001, IATF 16949, and strictly implementing quality inspection processes during production. Customers can understand their quality control capabilities and stability by reviewing past project cases, customer evaluations, or on-site investigation of their production site.

Thirdly, the rationality of cost and price is also one of the factors that enterprises must consider. Although low prices may bring economic benefits in the short term, sacrificing quality or delivery cycle may cause greater losses. Enterprises should comprehensively consider factors such as processing costs, transportation expenses, and after-sales service to choose suppliers with high cost-performance. At the same time, they should also pay attention to whether the supplier has the ability to produce on a large scale and maintain stable prices and service levels in bulk orders.

Fourthly, delivery cycle and response speed are important factors affecting supply chain efficiency. When selecting a supplier, enterprises should understand whether the supplier's production plan is reasonable and whether they have the ability to flexibly respond to order changes. Especially in industries with fast product upgrades and changing market demand, the supplier's ability to respond quickly to customer needs directly affects the enterprise's market response capability.

Finally, after-sales service and the potential for long-term cooperation should not be overlooked. High-quality sheet metal manufacturing suppliers not only provide products but also offer technical support, maintenance services, and continuous improvement suggestions during the product usage process. Establishing a long-term and stable cooperative relationship is conducive to achieving a win-win situation for both parties in terms of technological research and development, cost control, and supply chain optimization.

In summary, when selecting a sheet metal manufacturing supplier, enterprises should comprehensively consider various factors such as technical capabilities, quality management, cost control, delivery efficiency, and service support. Through scientific evaluation and on-site investigation, they should screen out the most suitable partner for their own needs. Only in this way can they gain a competitive advantage in the fierce market competition and achieve sustainable development.

Firstly, investigating the technical strength and production capacity of the supplier is a key step in choosing a sheet metal manufacturing service provider. Enterprises should understand whether the supplier has advanced equipment such as CNC punch presses, laser cutting machines, and bending machines, as well as the degree of automation and processing accuracy of their equipment. In addition, they also need to pay attention to the professional capabilities of their technical team, whether they have the ability to provide one-stop services from design to finished product manufacturing, and whether they can handle the processing requirements of complex structural components.

Secondly, the quality management system is an important standard for measuring the reliability of suppliers. Excellent sheet metal manufacturing suppliers usually have a sound quality control system, such as passing international quality management system certifications such as ISO 9001, IATF 16949, and strictly implementing quality inspection processes during production. Customers can understand their quality control capabilities and stability by reviewing past project cases, customer evaluations, or on-site investigation of their production site.

Thirdly, the rationality of cost and price is also one of the factors that enterprises must consider. Although low prices may bring economic benefits in the short term, sacrificing quality or delivery cycle may cause greater losses. Enterprises should comprehensively consider factors such as processing costs, transportation expenses, and after-sales service to choose suppliers with high cost-performance. At the same time, they should also pay attention to whether the supplier has the ability to produce on a large scale and maintain stable prices and service levels in bulk orders.

Fourthly, delivery cycle and response speed are important factors affecting supply chain efficiency. When selecting a supplier, enterprises should understand whether the supplier's production plan is reasonable and whether they have the ability to flexibly respond to order changes. Especially in industries with fast product upgrades and changing market demand, the supplier's ability to respond quickly to customer needs directly affects the enterprise's market response capability.

Finally, after-sales service and the potential for long-term cooperation should not be overlooked. High-quality sheet metal manufacturing suppliers not only provide products but also offer technical support, maintenance services, and continuous improvement suggestions during the product usage process. Establishing a long-term and stable cooperative relationship is conducive to achieving a win-win situation for both parties in terms of technological research and development, cost control, and supply chain optimization.

In summary, when selecting a sheet metal manufacturing supplier, enterprises should comprehensively consider various factors such as technical capabilities, quality management, cost control, delivery efficiency, and service support. Through scientific evaluation and on-site investigation, they should screen out the most suitable partner for their own needs. Only in this way can they gain a competitive advantage in the fierce market competition and achieve sustainable development.