News

How to calculate the cutting speed in turning operations

Category:answer Publishing time:2025-10-31 15:15:45 Browse: Times

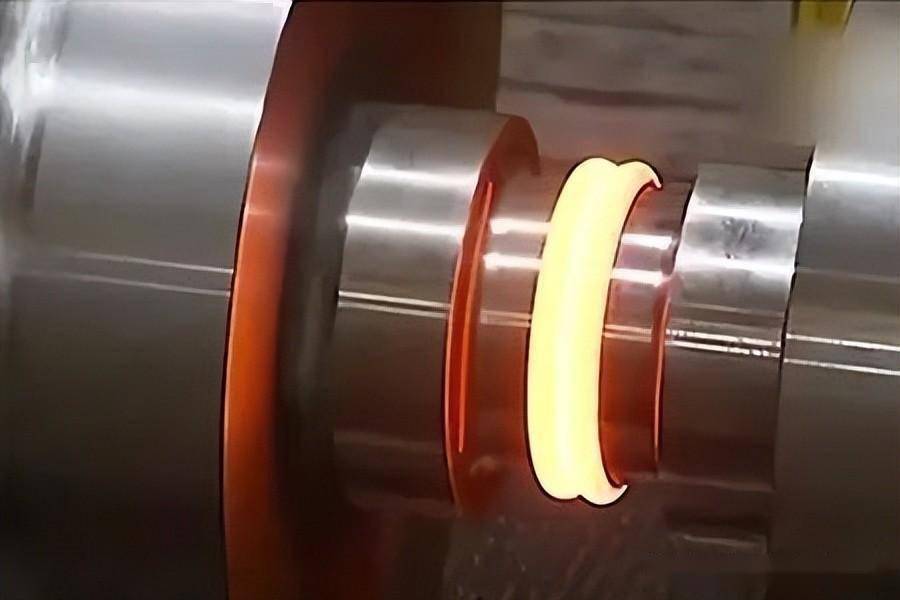

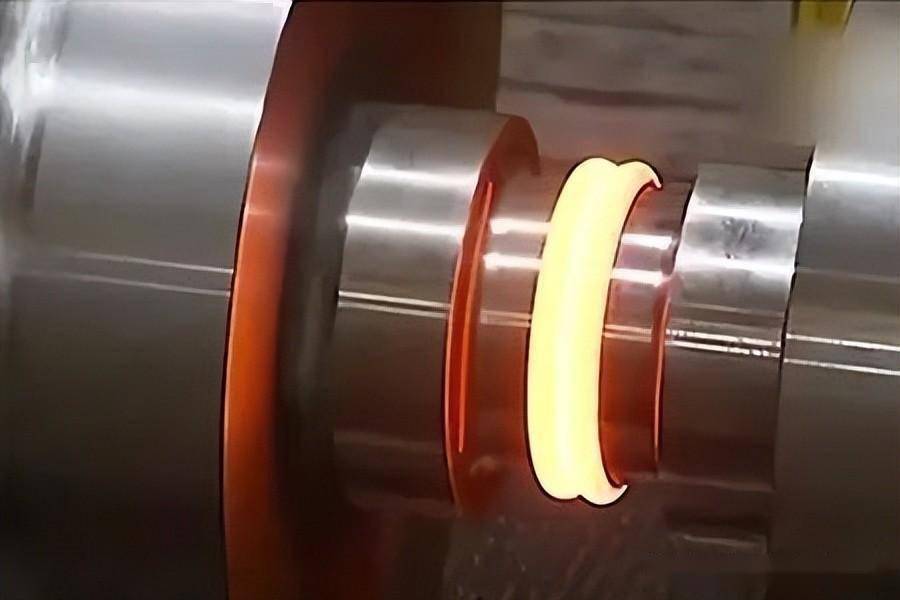

In metal cutting processes, cutting speed (Cutting Speed) is a very critical parameter that directly affects processing efficiency, tool life, and surface quality of the processed parts. Especially in turning operations, the rational selection of cutting speed is crucial for improving production efficiency and ensuring the quality of the processed parts. This article will introduce in detail the definition, calculation method, and influencing factors of cutting speed in turning operations.

## Definition of Cutting Speed

The cutting speed usually refers to the relative motion speed of the workpiece surface to the cutting edge of the tool, and its unit is usually meters per minute (m/min) or feet per minute (ft/min). In turning operations, the workpiece rotates and the tool feeds, so the cutting speed refers to the linear velocity of a point on the outer surface of the workpiece.

## Two, the calculation formula of cutting speed

The cutting speed can be calculated by the following formula:

V_c = \frac{\pi \cdot D \cdot n}{1000}

Among them:

- $ V_c $: cutting speed, unit m/min;

- $ D $: the diameter of the workpiece to be processed, unit mm;

- $ n $: spindle speed, unit r/min (revolutions per minute);

- π: the circle constant, about 3.1416.

The division by 1000 in the formula is to convert the diameter from millimeters to meters, so as to obtain the cutting speed in meters per minute.

For example:

Assuming the diameter of the workpiece is 50 mm and the spindle speed of the machine tool is 800 r/min, the calculation of the cutting speed is as follows:

V_c = \frac{3.1416 \cdot 50 \cdot 800}{1000} ≈ 125.66 \, \text{m/min}

## Three, how to choose the appropriate cutting speed based on the material

The selection of cutting speed is related to many factors such as workpiece material, tool material, and cooling conditions. Generally speaking:

- Workpiece material: the higher the hardness, the lower the cutting speed should be; for example, the cutting speed of casting iron is usually lower than that of aluminum alloy.

- Tool material:

- High-speed steel (HSS): lower cutting speed, generally 30~80 m/min;

- Hard alloy blade: higher cutting speed, up to 100~300 m/min;

- Ceramic or CBN tools: suitable for high-speed cutting.

- Use of cutting fluid: the use of cutting fluid can increase cutting speed and extend tool life;

- Machining type: rough machining generally adopts lower cutting speed and larger cutting depth, while finishing machining is the opposite.

## Four, deducing the spindle speed based on the cutting speed

In actual operation, we often know the recommended cutting speed and need to deduce the spindle speed to set the machine tool parameters. At this time, the following formula can be used:

n = \frac{1000 \cdot V_c}{\pi \cdot D}

Through this formula, it is convenient to set the spindle speed of the lathe to ensure operation at the appropriate cutting speed.

## Conclusion

Accurate calculation and selection of appropriate cutting speeds are important prerequisites for efficient and high-precision turning processing. By mastering the calculation method of cutting speeds and adjusting them in combination with actual materials, tools, and process conditions, it is possible to significantly improve processing efficiency, reduce costs, and extend tool life. Therefore, it is very necessary for mechanical processing technicians to understand and skillfully apply the calculation principles of cutting speeds.

In metal cutting processes, cutting speed (Cutting Speed) is a very critical parameter that directly affects processing efficiency, tool life, and surface quality of the processed parts. Especially in turning operations, the rational selection of cutting speed is crucial for improving production efficiency and ensuring the quality of the processed parts. This article will introduce in detail the definition, calculation method, and influencing factors of cutting speed in turning operations.

## Definition of Cutting Speed

The cutting speed usually refers to the relative motion speed of the workpiece surface to the cutting edge of the tool, and its unit is usually meters per minute (m/min) or feet per minute (ft/min). In turning operations, the workpiece rotates and the tool feeds, so the cutting speed refers to the linear velocity of a point on the outer surface of the workpiece.

## Two, the calculation formula of cutting speed

The cutting speed can be calculated by the following formula:

V_c = \frac{\pi \cdot D \cdot n}{1000}

Among them:

- $ V_c $: cutting speed, unit m/min;

- $ D $: the diameter of the workpiece to be processed, unit mm;

- $ n $: spindle speed, unit r/min (revolutions per minute);

- π: the circle constant, about 3.1416.

The division by 1000 in the formula is to convert the diameter from millimeters to meters, so as to obtain the cutting speed in meters per minute.

For example:

Assuming the diameter of the workpiece is 50 mm and the spindle speed of the machine tool is 800 r/min, the calculation of the cutting speed is as follows:

V_c = \frac{3.1416 \cdot 50 \cdot 800}{1000} ≈ 125.66 \, \text{m/min}

## Three, how to choose the appropriate cutting speed based on the material

The selection of cutting speed is related to many factors such as workpiece material, tool material, and cooling conditions. Generally speaking:

- Workpiece material: the higher the hardness, the lower the cutting speed should be; for example, the cutting speed of casting iron is usually lower than that of aluminum alloy.

- Tool material:

- High-speed steel (HSS): lower cutting speed, generally 30~80 m/min;

- Hard alloy blade: higher cutting speed, up to 100~300 m/min;

- Ceramic or CBN tools: suitable for high-speed cutting.

- Use of cutting fluid: the use of cutting fluid can increase cutting speed and extend tool life;

- Machining type: rough machining generally adopts lower cutting speed and larger cutting depth, while finishing machining is the opposite.

## Four, deducing the spindle speed based on the cutting speed

In actual operation, we often know the recommended cutting speed and need to deduce the spindle speed to set the machine tool parameters. At this time, the following formula can be used:

n = \frac{1000 \cdot V_c}{\pi \cdot D}

Through this formula, it is convenient to set the spindle speed of the lathe to ensure operation at the appropriate cutting speed.

## Conclusion

Accurate calculation and selection of appropriate cutting speeds are important prerequisites for efficient and high-precision turning processing. By mastering the calculation method of cutting speeds and adjusting them in combination with actual materials, tools, and process conditions, it is possible to significantly improve processing efficiency, reduce costs, and extend tool life. Therefore, it is very necessary for mechanical processing technicians to understand and skillfully apply the calculation principles of cutting speeds.