News

How to avoid zinc peeling in the sheet metal processing of galvanized steel plates

Category:answer Publishing time:2025-12-14 16:38:34 Browse: Times

Galvanized steel plate, due to its excellent corrosion resistance, is widely used in sheet metal processing in fields such as construction, automobiles, home appliances, and industrial equipment. However, during the actual processing and use, galvanized steel plates often suffer from zinc peeling, which not only affects the appearance of the product but also reduces its protective performance and shortens its service life. Therefore, how to effectively avoid zinc peeling in the sheet metal processing process of galvanized steel plates has become a key concern for engineering and technical personnel.

1. Understand the structure and characteristics of galvanized steel plate

Galvanized steel plate is a material that improves its corrosion resistance by applying a layer of zinc on the surface of the steel plate. The adhesion of the zinc layer is closely related to its thickness and plating method (such as electroplating zinc or hot-dip galvanized zinc). Generally, the zinc layer of hot-dip galvanized is thicker and has stronger adhesion, while electroplating zinc is thinner and smoother on the surface, but has relatively lower adhesion. Therefore, it is necessary to clarify the material type before processing and choose the appropriate processing method.

2. Rational design of processing technology

1. Control of stamping and bending radius

During stamping and bending processes, if the bending radius is too small, the zinc layer may peel off due to excessive plastic deformation. Therefore, the appropriate bending radius should be selected according to the plate thickness, generally recommended to be not less than 1 times the plate thickness to reduce the risk of zinc layer delamination.

2. Mold design and maintenance

The surface roughness and wear degree of the mold directly affect the stress condition of the galvanized steel plate during processing. Using smooth, burr-free molds can effectively reduce the friction damage to the zinc layer. At the same time, regular maintenance of the mold should be carried out to prevent processing defects caused by mold aging.

3. Control processing speed and pressure

Excessive stamping speed and pressure can cause the zinc layer to bear excessive shearing force and lead to peeling off. Appropriate reduction of processing speed and adjustment of stamping parameters can help protect the integrity of the zinc layer.

3. Strengthen surface treatment and protective measures

1. Pretreatment process

Before welding, spraying, and other subsequent processing, appropriate cleaning treatment should be carried out on the galvanized steel plate to remove surface oil, dust, and other impurities to prevent surface contamination from affecting the stability of the zinc layer.

2. Welding process control

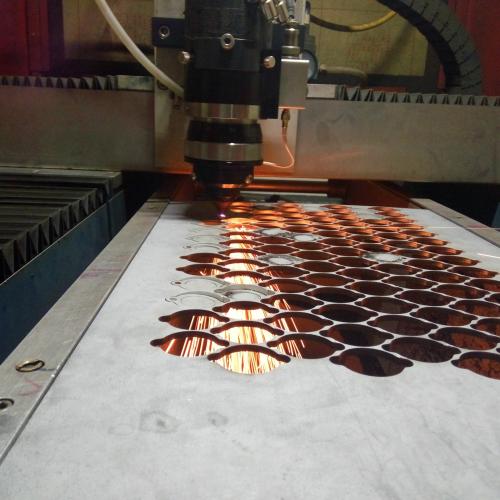

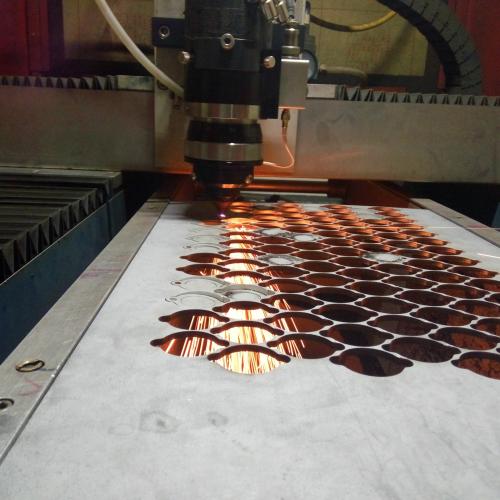

During the welding process, high temperature is prone to cause evaporation or burning of the zinc layer. It is recommended to use welding methods with less thermal impact such as laser welding and spot welding; if traditional arc welding is used, the welding current and time should be controlled as much as possible, and the weld area should be cleaned up in time after welding, and zinc plating treatment should be carried out if necessary.

3. Post-treatment and coating protection

For areas where slight zinc loss has occurred, zinc-rich primer can be used for touch-up painting to restore its corrosion resistance. In addition, spray painting or coating treatment after sheet metal processing can also play a secondary protective role.

4. Rational storage and transportation management

During storage and transportation, galvanized steel plates should be avoided from getting damp or being rained on to prevent the zinc layer from contacting moisture vapor and producing white rust. At the same time, it is necessary to prevent heavy objects from being pressed and collided with, to avoid physical damage causing zinc loss.

Conclusion

Galvanized steel plate has a wide range of application value in sheet metal processing, but the issue of zinc loss should not be neglected. By reasonably selecting materials, optimizing processing technology, strictly controlling the welding and surface treatment process, and doing a good job of storage management, the risk of zinc loss can be significantly reduced, and the product quality and service life can be improved. Only through collaborative control at all stages from design, processing to subsequent treatment can the efficient and high-quality manufacturing of galvanized steel sheet metal products truly be realized.

Galvanized steel plate, due to its excellent corrosion resistance, is widely used in sheet metal processing in fields such as construction, automobiles, home appliances, and industrial equipment. However, during the actual processing and use, galvanized steel plates often suffer from zinc peeling, which not only affects the appearance of the product but also reduces its protective performance and shortens its service life. Therefore, how to effectively avoid zinc peeling in the sheet metal processing process of galvanized steel plates has become a key concern for engineering and technical personnel.

1. Understand the structure and characteristics of galvanized steel plate

Galvanized steel plate is a material that improves its corrosion resistance by applying a layer of zinc on the surface of the steel plate. The adhesion of the zinc layer is closely related to its thickness and plating method (such as electroplating zinc or hot-dip galvanized zinc). Generally, the zinc layer of hot-dip galvanized is thicker and has stronger adhesion, while electroplating zinc is thinner and smoother on the surface, but has relatively lower adhesion. Therefore, it is necessary to clarify the material type before processing and choose the appropriate processing method.

2. Rational design of processing technology

1. Control of stamping and bending radius

During stamping and bending processes, if the bending radius is too small, the zinc layer may peel off due to excessive plastic deformation. Therefore, the appropriate bending radius should be selected according to the plate thickness, generally recommended to be not less than 1 times the plate thickness to reduce the risk of zinc layer delamination.

2. Mold design and maintenance

The surface roughness and wear degree of the mold directly affect the stress condition of the galvanized steel plate during processing. Using smooth, burr-free molds can effectively reduce the friction damage to the zinc layer. At the same time, regular maintenance of the mold should be carried out to prevent processing defects caused by mold aging.

3. Control processing speed and pressure

Excessive stamping speed and pressure can cause the zinc layer to bear excessive shearing force and lead to peeling off. Appropriate reduction of processing speed and adjustment of stamping parameters can help protect the integrity of the zinc layer.

3. Strengthen surface treatment and protective measures

1. Pretreatment process

Before welding, spraying, and other subsequent processing, appropriate cleaning treatment should be carried out on the galvanized steel plate to remove surface oil, dust, and other impurities to prevent surface contamination from affecting the stability of the zinc layer.

2. Welding process control

During the welding process, high temperature is prone to cause evaporation or burning of the zinc layer. It is recommended to use welding methods with less thermal impact such as laser welding and spot welding; if traditional arc welding is used, the welding current and time should be controlled as much as possible, and the weld area should be cleaned up in time after welding, and zinc plating treatment should be carried out if necessary.

3. Post-treatment and coating protection

For areas where slight zinc loss has occurred, zinc-rich primer can be used for touch-up painting to restore its corrosion resistance. In addition, spray painting or coating treatment after sheet metal processing can also play a secondary protective role.

4. Rational storage and transportation management

During storage and transportation, galvanized steel plates should be avoided from getting damp or being rained on to prevent the zinc layer from contacting moisture vapor and producing white rust. At the same time, it is necessary to prevent heavy objects from being pressed and collided with, to avoid physical damage causing zinc loss.

Conclusion

Galvanized steel plate has a wide range of application value in sheet metal processing, but the issue of zinc loss should not be neglected. By reasonably selecting materials, optimizing processing technology, strictly controlling the welding and surface treatment process, and doing a good job of storage management, the risk of zinc loss can be significantly reduced, and the product quality and service life can be improved. Only through collaborative control at all stages from design, processing to subsequent treatment can the efficient and high-quality manufacturing of galvanized steel sheet metal products truly be realized.